Minerals are the building blocks of our world, forming the foundation of everything from construction materials to precious gemstones. Understanding their composition is crucial across a spectrum of industries, informing decisions that impact everything from resource exploration to environmental protection. This is where X-ray fluorescence (XRF) mineral analyzers step in, offering a revolutionary tool for identifying and analyzing mineral elements with unparalleled accuracy and efficiency.

Why Using XRF Mineral Analyzers

Traditionally, mineral analysis involved complex laboratory procedures that were often time-consuming, destructive, and required specialized expertise. Enter XRF, a non-invasive technique that utilizes X-rays to excite atoms within a material, causing them to fluoresce at specific wavelengths unique to their elemental composition. By measuring these fluorescent signals, XRF analyzers can quickly and accurately determine the precise elemental makeup of a sample, providing invaluable insights into its properties and applications.

But why choose XRF over other methods? The advantages are numerous:

- Accuracy and Speed: XRF provides fast and accurate measurements of the elemental composition of minerals. Depending on the type of analyzer and the complexity of the sample, results can be obtained in seconds or minutes, with typical detection limits in the parts per million (ppm) range.

- Non-destructive Analysis: XRF is a non-destructive technique, meaning it does not require grinding or dissolving the sample, which can alter its composition. This allows for analysis of valuable or unique specimens without damaging them.

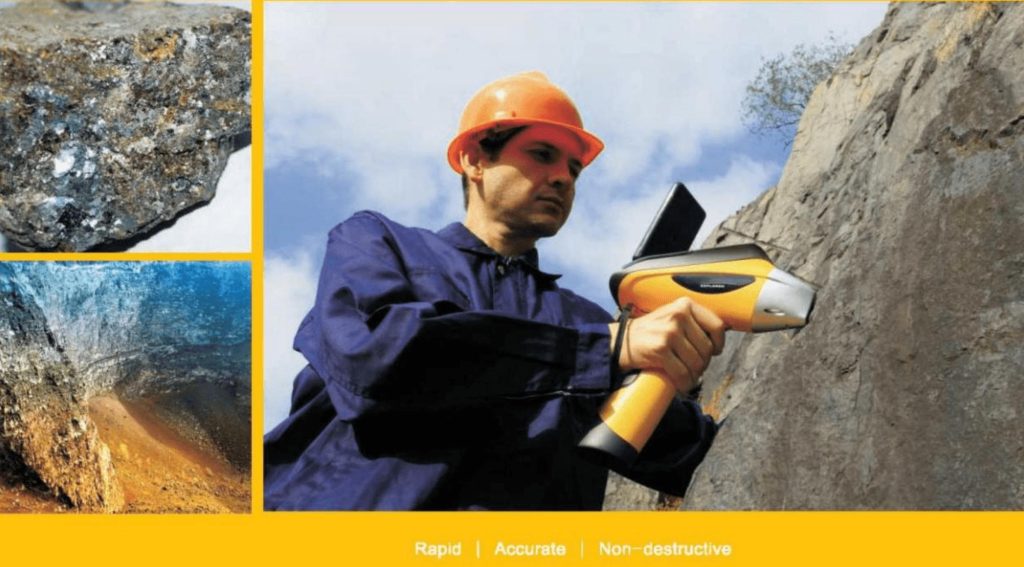

- Portability: Handheld XRF analyzers are available, making it possible to conduct mineral analysis in the field, at mine sites, or even during geological surveys. This allows for rapid decision-making and real-time data collection.

- Multi-elemental Analysis: XRF can simultaneously analyze for multiple elements present in a mineral, providing a comprehensive understanding of its composition. This is particularly useful for identifying specific minerals or characterizing mineral assemblages.

- Ease of Use: XRF analyzers are relatively easy to operate, even for users with limited technical experience. Many modern instruments have intuitive software and straightforward data interpretation tools.

- Cost-effectiveness: Compared to other techniques for mineral analysis, such as electron microprobe analysis (EMPA) or inductively coupled plasma mass spectrometry (ICP-MS), XRF is often more cost-effective, especially for routine analysis.

- Versatility: XRF can be used to analyze a wide variety of mineral types, including ores, gemstones, industrial minerals, and even archaeological artifacts.

However, it’s important to note that XRF also has limitations:

Light elements: Lighter elements, such as hydrogen and lithium, are not easily detected by XRF due to their lower energy X-rays.

Matrix effects: The presence of certain elements in a sample can interfere with the analysis of other elements, requiring additional calibration or data correction.

Bulk analysis: XRF provides information about the average elemental composition of the analyzed area, not the distribution of elements within the sample.

Despite these limitations, XRF remains a valuable tool for mineral analysis due to its speed, accuracy, ease of use, and versatility.

How to Use XRF Mineral Analyzers in Material Identification?

Here’s a general guide on how to use XRF mineral analyzers in material identification:

1. Prepare the sample

Clean the sample to remove any surface dirt or contamination that could interfere with the analysis.

If the sample is too large, you may need to crush or grind it into a smaller size.

For some types of XRF analyzers, you may need to prepare the sample in a specific way, such as making a powder or pressing it into a pellet.

2. Place the sample in the analyzer

Follow the instructions for your specific XRF analyzer to position the sample correctly.

Some XRF analyzers have a built-in sample chamber, while others require you to hold the sample in front of the X-ray source.

3. Run the analysis

Once the sample is in place, start the analysis.

The XRF analyzer will irradiate the sample with X-rays and measure the fluorescent X-rays that are emitted.

The analysis time can vary depending on the type of XRF analyzer and the settings you choose.

4. Analyze the results

The XRF analyzer will display the results of the analysis on its screen or computer software.

The results will typically show a list of the elements that were detected in the sample, along with their concentrations.

You can use the results to identify the material, or to compare it to known materials.

Here are some additional tips for using XRF mineral analyzers:

- Choose the right type of XRF analyzer for your needs. There are many different types of XRF analyzers available, with different capabilities and price points.

- Calibrate the XRF analyzer regularly. This will ensure that the results of your analyses are accurate.

- Use reference materials to verify the accuracy of your results.

- If you are not familiar with XRF analysis, it is a good idea to get training from a qualified professional.

By following these tips, you can use XRF mineral analyzers to quickly and easily identify the elemental composition of materials. Drawell can provide you different types of XRF analyzer and also can teach you how to use it. Please feel free to contact them for any needs.

How to Choose the XRF Mineral Analyzer?

There are two types of XRF mineral analyzers: Portable XRF Analyzers and desktop XRF mineral analyzers. They both are powerful tools for identifying the elemental composition of materials, but they have some key differences that make them suitable for different situations.

| Feature | Portable XRF | Desktop XRF |

| Portability | Highly portable | Stationary |

| Performance | Lower detection limits, less analytical power | Higher detection limits, more analytical power |

| Cost | More affordable | More expensive |

| Applications | Field applications | Laboratory applications |

Conclusion

In conclusion, XRF mineral analyzers represent a transformative leap in material identification. It have revolutionized mineral analysis, transforming how we explore, utilize, and protect Earth’s valuable resources. Their unmatched accuracy, speed, and non-destructive nature empower decision-making across diverse industries, from unlocking the secrets of the earth’s composition to ensuring the quality and safety of everyday materials. As XRF technology continues to evolve, its impact on our understanding and utilization of minerals is set to become even more profound, shaping the way we interact with the very foundation of our world.