The growing demand for food safety and quality has driven the adoption of advanced analytical techniques to ensure products meet regulatory standards. UV-Vis spectrophotometer adopting ultraviolet (UV) and visible (Vis) light, allows for the precise analysis of a wide range of food components, contaminants, and additives, becoming a essential tool in food inspection. Its applications in food inspection span from monitoring chemical composition to detecting adulteration and ensuring compliance with food safety regulations.

What is a UV-Vis Spectrophotometer

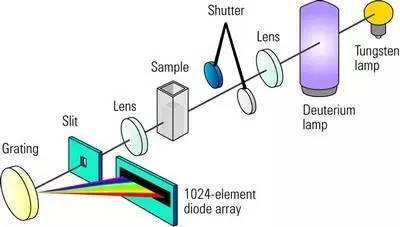

A UV-Vis spectrophotometer is an analytical instrument used to measure the absorbance of ultraviolet (UV) and visible (Vis) light by a substance. It works by passing light through a sample and detecting how much of that light is absorbed at different wavelengths. The resulting absorbance data is used to analyze the concentration of specific compounds, identify substances, or assess the purity of samples. UV-Vis spectrophotometry is widely used in fields like chemistry, biology, food inspection, etc, for precise and non-destructive analysis.

Why Choosing a UV-Vis Spectrophotometer in Food Inspection

| Reason | Description | Benefits |

| Accurate Quantification of Nutrients | Measures absorbance of key food components like vitamins, proteins, and sugars. | – High accuracy in nutrient concentration – Ensures product quality and consistency |

| Detection of Adulteration | Identifies the presence of inferior or foreign substances in food products. | – Protects against fraud – Ensures product integrity and safety |

| Monitoring Additives and Preservatives | Analyzes food colorants, additives, and preservatives for regulatory compliance. | – Ensures food safety – Maintains acceptable levels of additives |

| Sensitive Detection of Contaminants | Detects harmful substances like heavy metals, pesticides, and mycotoxins. | – Protects consumer health – Complies with safety regulations |

| Non-Destructive Analysis | Provides a non-invasive way to analyze food samples without altering or destroying them. | – Preserves sample integrity – Minimizes waste and cost |

| Rapid and Cost-Effective | Delivers fast results with minimal sample preparation. | – Reduces time spent in analysis – Low operational costs compared to other techniques |

| Versatile for Different Food Types | Applicable to a wide range of food matrices, from solids to liquids. | – Highly adaptable for different industries – Covers a broad spectrum of food inspection needs |

Key Applications of UV-Vis Spectrophotometer in Food Inspection

1. Determining Nutritional Content

UV-Vis spectrophotometer is commonly used to quantify key nutrients in food products, such as vitamins, proteins, and sugars. The technique measures the absorbance of specific wavelengths of light by these compounds, enabling accurate assessment of their concentration.

- Vitamin Analysis: For example, vitamins such as B1 (thiamine) and B2 (riboflavin) exhibit characteristic absorption peaks in the UV range. By measuring these peaks, the UV-Vis spectrophotometer can determine the concentration of vitamins in fortified foods and dietary supplements.

- Protein Content: Proteins, particularly those containing aromatic amino acids, absorb light in the UV range (around 280 nm). UV-Vis spectrophotometry can be used to assess protein levels in food products like dairy and meat, providing insight into nutritional quality.

- Sugar Determination: Certain sugars, when derivatized with specific reagents, form chromophores that absorb light in the visible range. This allows UV-Vis spectrophotometers to determine the sugar content in products such as fruit juices and beverages.

2. Detecting Food Adulteration

Food adulteration poses significant risks to both public health and brand integrity. UV-Vis spectrophotometry helps detect the presence of unwanted substances or inferior ingredients that may have been intentionally or unintentionally added to food products.

- Oil and Fat Adulteration: UV-Vis spectrophotometry is used to detect adulteration in edible oils, such as the addition of cheaper oils (e.g., palm oil in olive oil). By measuring absorption spectra, inspectors can identify discrepancies in the chemical composition that suggest adulteration.

- Honey Adulteration: In honey, UV-Vis spectrophotometry can detect the addition of sugar syrups by identifying the presence of specific markers that are absent in pure honey.

3. Analyzing Food Additives and Preservatives

Many food products contain additives, colorants, and preservatives, which must be monitored to ensure they are within permissible levels. The UV-Vis spectrophotometer is highly effective in analyzing these compounds due to their light-absorbing properties.

- Food Colorants: Artificial and natural colorants are often measured using UV-Vis spectrophotometry. The technique can identify and quantify the concentration of food dyes such as tartrazine (yellow) and sunset yellow by analyzing their absorbance spectra at specific wavelengths.

- Preservative Detection: Common preservatives, such as sodium benzoate and sorbic acid, exhibit unique absorption characteristics in the UV range. UV-Vis spectrophotometry allows inspectors to verify that these substances are present within legal limits in processed foods.

4. Monitoring Contaminants and Toxins

Contaminants such as heavy metals, pesticides, and mycotoxins present serious health risks when found in food products. UV-Vis spectrophotometer plays a crucial role in detecting these harmful substances.

- Mycotoxin Detection: Mycotoxins, which are toxic compounds produced by certain fungi, can contaminate crops such as corn and peanuts. Specific mycotoxins, like aflatoxins, absorb UV light, making UV-Vis spectrophotometry a valuable tool for their detection.

- Pesticide Residues: UV-Vis spectrophotometry, in combination with other analytical techniques, is used to detect pesticide residues in fruits, vegetables, and cereals. It helps ensure that the levels of these chemicals remain within the safety thresholds set by regulatory authorities.

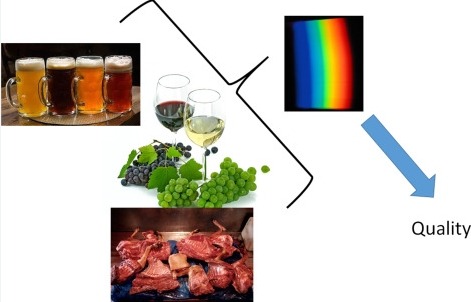

5. Quality Control in Beverage Industry

In the beverage industry, UV-Vis spectrophotometry is used extensively for quality control purposes. It allows for the analysis of color, turbidity, and clarity, which are critical factors in ensuring product consistency and customer satisfaction.

- Beer and Wine Quality: The UV-Vis spectrophotometer can monitor the color and clarity of beer and wine, providing quality control data on phenolic compounds, which affect the taste, color, and stability of these beverages.

- Juice Clarity: The presence of haze or turbidity in fruit juices can indicate quality degradation or contamination. UV-Vis spectrophotometry helps quantify turbidity and color to ensure that juices meet product specifications.

6. Detecting Spoilage Indicators

Food spoilage often results from microbial contamination, leading to the production of byproducts that can be monitored using UV-Vis spectrophotometry. For instance, certain spoilage organisms produce metabolites that absorb UV light, which can be detected to assess food freshness.

- Lipid Oxidation: In fats and oils, spoilage often occurs due to oxidation, which produces compounds that absorb UV light. By measuring these compounds, UV-Vis spectrophotometry can monitor the onset of rancidity in oils and fats, enabling timely quality control interventions.

- Protein Degradation: The breakdown of proteins in perishable foods, such as meat and fish, can lead to the production of UV-absorbing compounds. UV-Vis spectrophotometry helps in detecting these degradation products, offering a way to monitor spoilage.

7. Ensuring Regulatory Compliance

Food inspection using UV-Vis spectrophotometry helps manufacturers comply with local and international food safety regulations. By accurately measuring nutrient content, contaminants, and additives, this technology ensures that food products meet safety standards and legal requirements.

For instance, international regulations like those from the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) set strict limits on the presence of contaminants and additives in food products. UV-Vis spectrophotometer plays a crucial role in verifying compliance, ensuring that products are safe for consumers and can be legally sold in the market.

Overall, the ability to precisely analyze nutrients, detecting adulteration, measuring additives, monitoring contaminants, etc, makes UV-Vis spectrophotometer a powerful tool across the food industry. With increasing concerns over food safety, the use of this versatile technology is set to grow, contributing to better consumer protection and enhanced quality control in food production and processing.