A muffle furnace is a powerful tool used in laboratories and industrial settings for high-temperature applications. Whether you need to heat-treat materials, perform material testing, or conduct ashing experiments, understanding how to properly use a muffle furnace is crucial. This article provides a comprehensive guide on the operation of a muffle furnace, from setup to temperature control and sample handling. By following these steps, you can maximize the effectiveness and safety of your experiments while achieving accurate and consistent results.

1. Safety Precautions of Muffle Furnace Use

- Put on appropriate personal protective equipment (PPE) such as heat-resistant gloves, goggles, and a lab coat.

- Ensure the workspace is clear of any flammable materials and well-ventilated.

- Familiarize yourself with the emergency shutdown procedures and location of fire safety equipment.

- Preparing the Furnace of Muffle Furnace Use

- Check the power supply and ensure it is properly grounded.

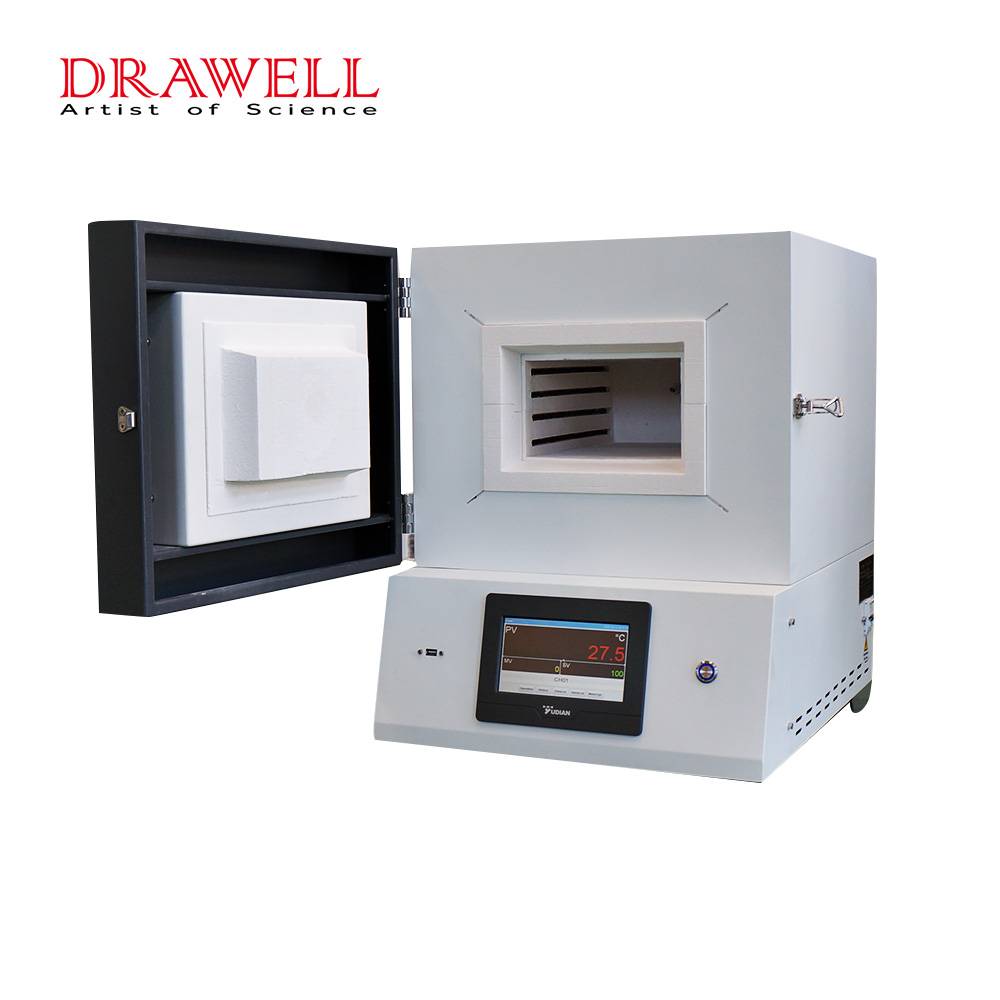

- Ensure the muffle chamber is clean and free from any debris or previous samples.

- Ensure that the muffle, the heating chamber, is securely inserted into the furnace and properly closed.

3. Setting the Temperature of Muffle Furnace Use

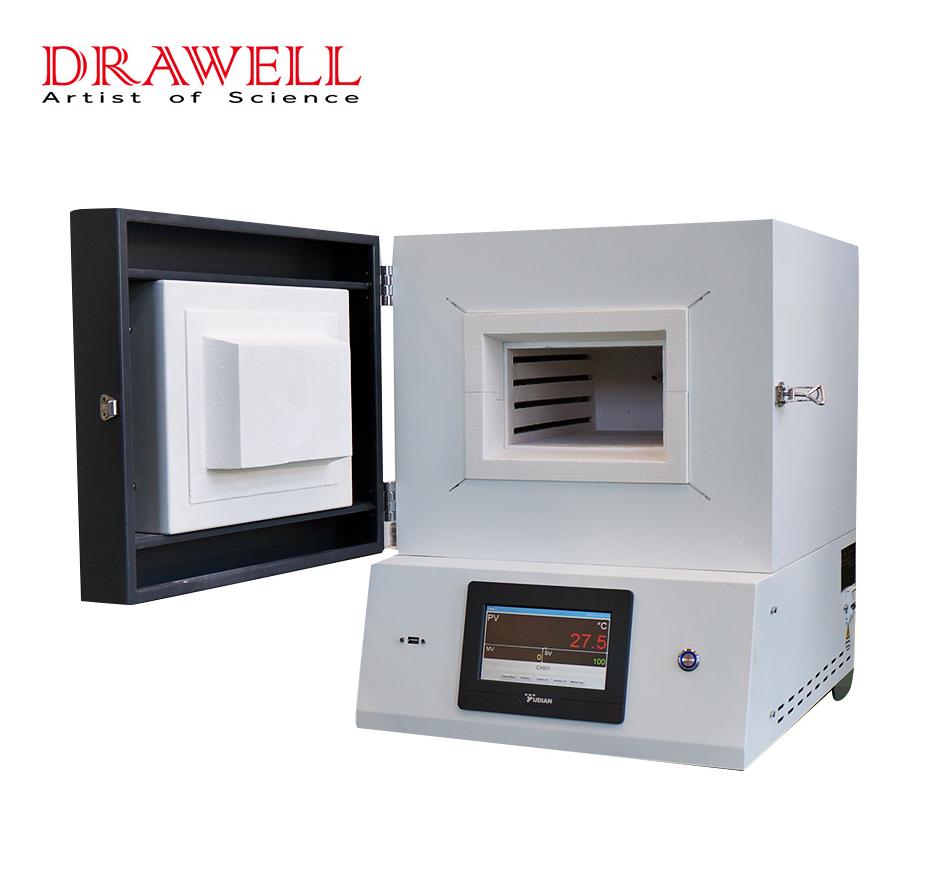

- Consult the operating manual for your specific muffle furnace model to understand its temperature control system.

- Use the temperature control knobs or digital display to set the desired temperature for your experiment.

- Take note of any specific heating rate or ramping instructions if required for your application.

4. Loading the Sample of Muffle Furnace Use

- Prepare your sample according to the specific requirements of your experiment.

- Use appropriate crucibles or containers that can withstand high temperatures.

- Ensure the sample is properly positioned within the muffle chamber for accurate heating.

5. Closing the Furnace of Muffle Furnace Use

- Once the sample is loaded, close the muffle furnace securely.

- Ensure that the furnace door is tightly sealed to prevent heat loss during operation.

6. Starting the Heating Process of Muffle Furnace Use

- Turn on the power supply and activate the muffle furnace according to the manufacturer’s instructions.

- The heating elements will start generating heat, and the furnace will begin to heat up towards the set temperature.

7. Monitoring the Process of Muffle Furnace Use

- Keep an eye on the temperature display or indicator throughout the heating process.

- Periodically check the temperature inside the muffle chamber to ensure it is reaching and maintaining the desired temperature.

- Avoid unnecessary opening of the furnace door to prevent heat loss and temperature fluctuations.

8. Cooling Down of Muffle Furnace Use

- Once the desired heating cycle is complete, gradually decrease the temperature of the furnace following your experimental requirements.

- Allow the furnace to cool down to a safe temperature before opening the door.

9. Retrieving the Sample of Muffle Furnace Use

- Once the furnace has cooled down sufficiently, open the door carefully.

- Use appropriate tools such as tongs or heat-resistant gloves to remove the sample from the muffle chamber.

- Be cautious as the sample may still be hot.

10. Cleaning and Maintenance of Muffle Furnace Use

- After completing your experiment, clean the muffle furnace by removing any residue or debris left behind from the sample.

- Follow the manufacturer’s instructions for specific cleaning and maintenance procedures to ensure the longevity of the furnace.

Conclusion

In conclusion, knowing how to use a muffle furnace correctly is essential for carrying out a wide range of high-temperature applications. By following the steps outlined in this guide, you can ensure the safe and efficient operation of your muffle furnace, as well as maintain the integrity of your samples. Always remember to prioritize safety precautions and consult the manufacturer’s instructions for your specific furnace model. With practice and adherence to proper techniques, you can harness the power of a muffle furnace to accomplish precise heat treatment, material testing, and other thermal processes with confidence.