A soxhlet extractor is a common scientific instrument used to extract soluble components from solid materials using a continuous solvent extraction technique. It is widely used in chemistry, pharmaceuticals, food testing, and environmental testing. In this article, we will discuss the topic of how to use a soxhlet extractor efficiently and safely.

What is a Soxhlet Extractor?

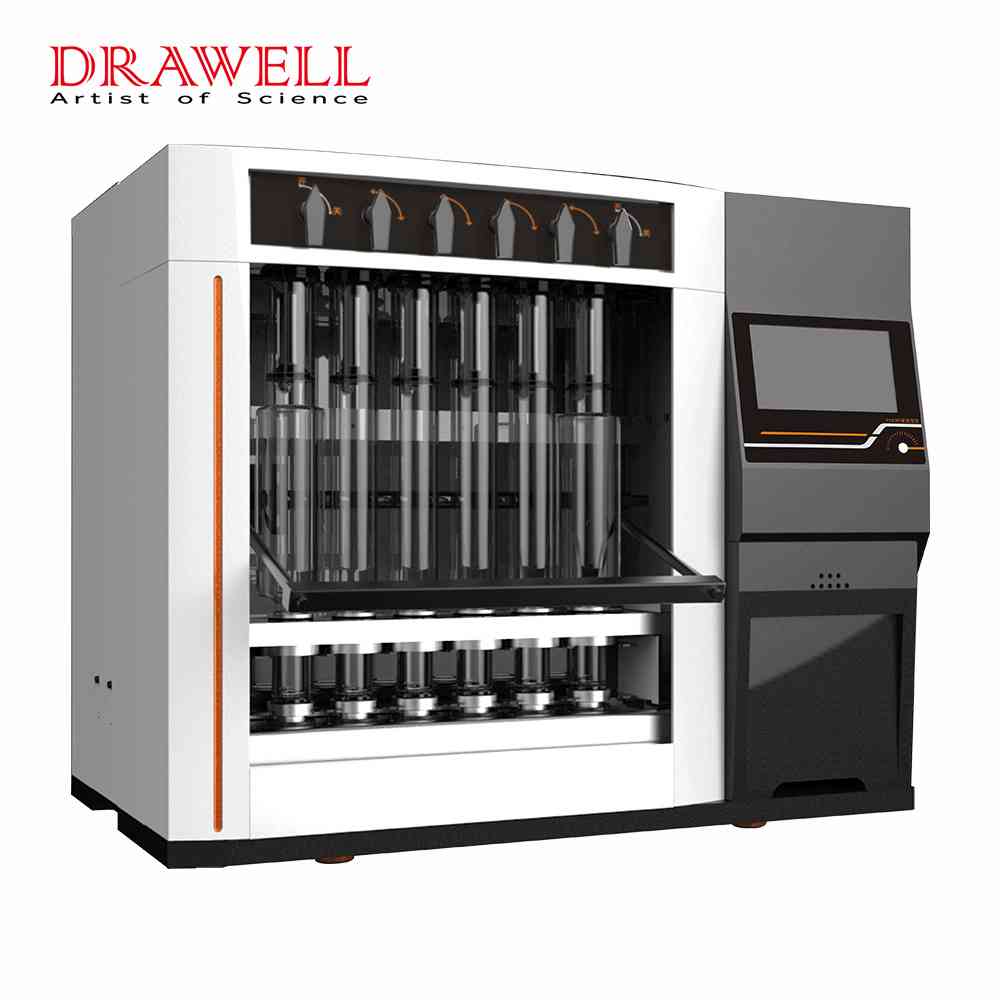

A round-bottom flask, a soxhlet extraction chamber, and a condenser comprise a soxhlet extractor. The extraction chamber, which is a thimble constructed of cellulose or other porous materials, is filled with the solid material to be removed. The solvent is circulated through the system constantly, allowing for optimal extraction.

Choosing the Solvent Before Using a Soxhlet Extractor

Choosing the right solvent is critical for a successful extraction. The solvent should have a higher boiling point than the substance to be extracted and be capable of successfully dissolving the target compound. Depending on the sort of substances you want to extract, common solvents include ethanol, methanol, chloroform, and hexane.

Assembling a Soxhlet Extractor

Assembling a Soxhlet extractor is a relatively simple operation, but it is critical to carefully follow the instructions to ensure good functionality and safety.

Step 1: Prepare the Round-bottom Flask

Place the round-bottom flask on a heat source with a consistent temperature, such as a heating mantle or hot plate. The flask will hold the solvent as well as serve as a reservoir for the extracted solution.

Step 2: Set Up the Soxhlet Extraction Chamber

Attach the soxhlet extraction chamber to the round-bottom flask’s top. The extraction chamber is a vertically extended tube that fits snugly around the flask’s neck. To prevent the solvent from escaping, it should have a tight and leak-proof connection.

Step 3: Insert the Soxhlet Extraction Thimble

Consider the soxhlet extraction thimble, a tiny cellulose or other porous material tube. Fill it with the solid material to be extracted. Make sure the thimble is large enough to fit inside the Soxhlet extraction chamber without hitting the walls.

Step 4: Secure the Condenser

Connect the condenser to the soxhlet extraction chamber’s top. The condenser is a cooling appliance that aids in the conversion of solvent vapor to liquid as it passes through the extraction process.

Step 5: Check Connections

Check all connections (flask, extraction chamber, condenser) to ensure they are secure and airtight before beginning the extraction process. To keep the system’s integrity, use rubber stoppers or glass joints to seal any gaps.

Loading the Solid Material in a Soxhlet Extractor

Weigh the material to be extracted and place it within a soxhlet extraction thimble. Ascertain that the thimble is constructed of a material that is resistant to the solvent being employed.

Starting the Extraction Process Using a Soxhlet Extractor

Fill the round-bottom flask halfway with the solvent of choice. The solvent volume should be sufficient to fill the extraction chamber but not so large that it causes overflow throughout the procedure.

Turn on the heat source, and the solvent will boil and vaporize. Due to cooling, the vapor will rise through the flask, enter the condenser, and condense into liquid form.

As the liquid solvent accumulates in the extraction chamber, it will progressively fill to a particular level before siphoning back into the round-bottom flask through the siphon arm.

Continuous Extraction Process in a Soxhlet Extractor

The soxhlet extractor works in a continuous cycle, with the solvent passing over the solid material repeatedly. The solvent dissolves the target chemical as it travels through the material, and upon recondensation in the round-bottom flask, it deposits the dissolved compounds. The process is repeated until the extracted compound’s concentration in the solvent achieves equilibrium.

To avoid problems, keep a watchful eye on the extraction process. To avoid overflow, keep an eye on the level of the solvent in the extraction chamber and flask. Adjust the heat source as needed to keep the solvent boiling gently and steadily.

Completion of Extraction Process in a Soxhlet Extractor

Depending on the nature of the solid material and the solvent’s efficacy, the soxhlet extraction procedure can take several hours. Turn off the heat source and allow the system to cool before handling the equipment once the extraction is complete.

After finishing the extraction, carefully remove the soxhlet extraction thimble containing the extracted chemical. To acquire the pure component, evaporate the solvent from the extracted solution.

Summary

A soxhlet extractor is an extremely useful equipment for extracting soluble chemicals from solid materials. You can use the Soxhlet extractor to obtain high-quality extracts for various analytical and research objectives by following the instructions indicated in this guide and paying attention to safety measures. To guarantee a successful and safe extraction operation, always handle the apparatus with care and follow normal laboratory safety practices.