In the realm of microbiological analysis, the accuracy and reliability of sample preparation are pivotal. The lab blender stomacher has emerged as a crucial tool, streamlining the homogenization of samples ranging from food products to environmental specimens. This article aims to provide a comprehensive guide on effectively using a lab blender stomacher, ensuring precise and reproducible results in microbiological analysis.

Understanding the Lab Blender Stomacher

Components

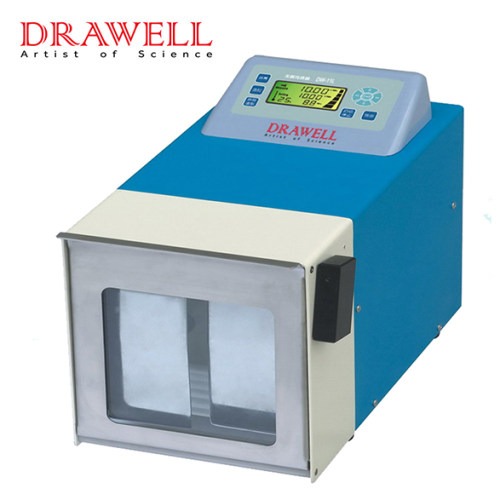

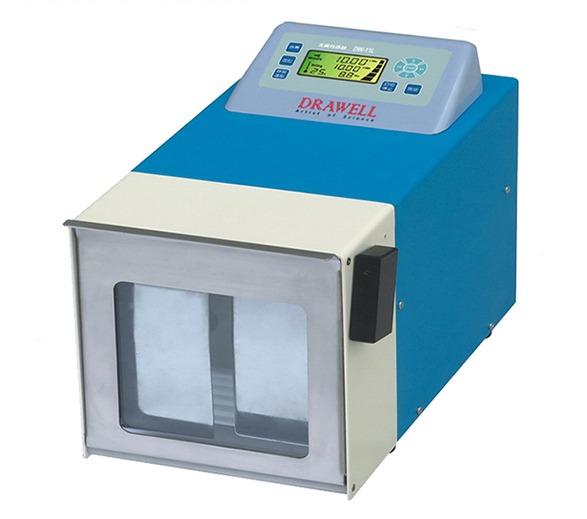

A lab blender stomacher is a sophisticated device designed for homogenizing samples by applying a combination of mechanical blending and agitation. Key components include:

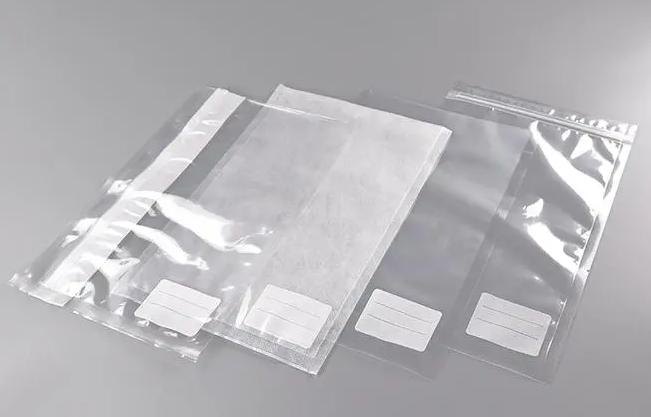

- Blending Bag: A sterile, leak-proof bag where the sample is placed. Various types exist, including plain and filter bags, catering to different sample types and analyses.

- Paddle Mechanism: Paddles within the stomacher that move back and forth, effectively crushing and mixing the sample within the bag.

- Motor: Drives the paddle mechanism, offering variable speeds and blending intensities.

- Control Panel: Allows the user to set parameters such as blending time, speed, and program.

Principles

The lab blender stomacher operates on the principle of mechanical blending combined with the pulverization of samples. The paddles exert a pressure that forces the sample to mix thoroughly within the blending bag, ensuring a uniform homogenate. This process is critical in microbiological analysis, as it ensures that microbial cells are evenly distributed, facilitating accurate detection and enumeration.

How to Use a Lab Blender Stomacher Effectively in Microbiological Analysis?

Using a lab blender stomacher effectively in microbiological analysis involves meticulous preparation, precise operation, and thorough post-processing. Here’s a detailed guide to ensure optimal results:

Preparation for Use

1. Choosing the Right Blending Bag

Sterility: Always use sterile blending bags to avoid introducing contaminants into your sample. Ensure the bags are sealed and stored in a sterile environment until use.

Type: Select the appropriate type of bag for your sample:

- Plain Bags: Suitable for general homogenization.

- Filter Bags: Ideal for samples with solid particles, as they allow the liquid to pass through while retaining solids, facilitating easier extraction of the homogenate.

2. Sample Preparation

Volume: Make sure the sample volume is compatible with the capacity of the blending bag and the stomacher. Overloading the bag can lead to leaks and inadequate blending.

Size: Cut larger samples into smaller, manageable pieces. This ensures more efficient and uniform blending. For hard or fibrous samples, smaller pieces reduce the risk of bag tears.

3. Stomacher Setup

Calibration: Regularly calibrate the stomacher according to the manufacturer’s instructions. This ensures that the blending times and speeds are accurate, contributing to reproducibility.

Bag Placement: Properly place the blending bag within the stomacher:

- Ensure the bag is centered and evenly distributed.

- Remove any air pockets by gently pressing down on the bag before sealing it.

- Make sure the bag is securely closed to prevent leaks during operation.

Setting Adjustments: Adjust the control panel settings to match the specific requirements of your sample and analysis:

- Blending Time: Typically ranges from 30 seconds to 2 minutes.

- Speed: Adjust according to the sample type. Softer samples may require lower speeds, while tougher samples might need higher speeds.

Running the Stomacher

1. Loading the Sample

Placement: Carefully place the sample into the blending bag, ensuring that it is evenly distributed.

Sealing: Seal the bag tightly to avoid any leaks during the blending process.

Securing the Bag: Load the sealed bag into the stomacher, ensuring it is properly aligned and securely fastened to prevent it from shifting during operation.

2. Operating the Machine

Program Selection: Choose the appropriate program based on the sample type and desired results. Some stomachers have preset programs for common sample types.

Time and Speed Settings: Set the blending time and speed according to the nature of your sample:

- Soft Samples: Typically require shorter blending times and lower speeds.

- Hard or Fibrous Samples: May need longer blending times and higher speeds to ensure complete homogenization.

Start the Machine: Once all settings are adjusted, start the stomacher and monitor its operation to ensure it is running smoothly.

3. Monitoring the Process

Observation: Keep an eye on the blending process to detect any issues such as leaks or improper mixing. Make adjustments as needed to optimize the homogenization.

Consistency: Ensure that the blending is consistent throughout the process. If blending appears uneven, consider stopping the machine to reposition the bag and restart.

Post-Processing

1. Sample Extraction

Careful Handling: After the blending cycle is complete, carefully remove the blending bag from the stomacher.

Sterile Techniques: Use sterile pipettes or tools to extract the homogenized sample from the bag, ensuring that the sample remains uncontaminated.

Filtering: If using a filter bag, allow the liquid homogenate to pass through the filter, leaving solids behind. This makes extraction easier and more precise.

2. Cleaning and Maintenance

Cleaning: Clean the stomacher and its components after each use:

- Wipe down all surfaces with a suitable disinfectant.

- If applicable, run a cleaning cycle as per the manufacturer’s instructions.

Maintenance: Regularly check and maintain the stomacher to ensure its longevity and reliability:

- Inspect the paddles for wear and tear and replace them if necessary.

- Check the motor and other mechanical components for any signs of malfunction.

3. Disposal of Blending Bags

Safety: Dispose of used blending bags according to your laboratory’s waste disposal protocols. This is especially important for samples that may contain pathogens or hazardous materials.

Biohazard Waste: Bags used for potentially hazardous samples should be treated as biohazard waste and disposed of accordingly, following proper safety guidelines.

Best Practices

Consistency and Reproducibility: Always use consistent sample preparation techniques and blending settings to ensure reproducibility of results.

Avoiding Contamination: Use sterile equipment and work in a clean environment to prevent cross-contamination between samples.

Documentation: Keep detailed records of blending settings and sample information to facilitate reproducibility and traceability.

By following these detailed steps and best practices, you can use a lab blender stomacher effectively in microbiological analysis, ensuring reliable and accurate results.

Common Issues and Troubleshooting Methods

Here are common issues that can arise when using a lab blender stomacher for microbiological samples, along with troubleshooting methods to address them:

1. Leaks and Bag Tears

Issue:

Blending bags may develop leaks or tears during the homogenization process, leading to sample loss and contamination.

Troubleshooting Methods:

- Bag Quality: Ensure you are using high-quality, durable blending bags designed for use with the stomacher.

- Overfilling: Avoid overfilling the blending bag. Leave sufficient headspace to prevent excessive pressure on the bag seams.

- Bag Placement: Ensure the bag is correctly positioned in the stomacher, with no folds or creases that could lead to punctures.

- Sample Size: Cut large or hard samples into smaller pieces to reduce stress on the bag.

2. Inconsistent Blending

Issue:

The sample is not uniformly homogenized, leading to inconsistent results in microbiological analysis.

Troubleshooting Methods:

Blending Time and Speed: Adjust the blending time and speed settings. For tougher samples, a longer blending time or higher speed may be necessary.

Sample Size: Ensure the sample pieces are uniform in size for even blending.

Bag Placement: Properly align the bag to ensure it sits flat and is evenly distributed within the stomacher.

3. Machine Errors and Malfunctions

Issue:

Operational errors or malfunctions occur during the stomacher’s operation, such as the paddles not moving or the machine stopping unexpectedly.

Troubleshooting Methods:

- Power Supply: Check the power supply and ensure the machine is properly plugged in and switched on.

- Calibration: Regularly calibrate the stomacher according to the manufacturer’s instructions to maintain optimal performance.

- Overheating: Allow the machine to cool down if it has been in use for an extended period, as overheating can cause malfunctions.

- Technical Support: Refer to the user manual for error codes and troubleshooting steps. Contact technical support if issues persist.

4. Cross-Contamination

Issue:

Contamination between samples can occur, leading to inaccurate microbiological results.

Troubleshooting Methods:

- Sterile Technique: Use sterile blending bags and tools to handle samples. Work in a clean environment to prevent contamination.

- Cleaning: Thoroughly clean the stomacher after each use, following the manufacturer’s recommended cleaning procedures.

- Separation: Process high-risk samples (e.g., pathogens) separately from other samples to avoid cross-contamination.

5. Noise and Vibration

Issue:

Excessive noise and vibration during operation can indicate issues with the machine or improper setup.

Troubleshooting Methods:

- Machine Placement: Ensure the stomacher is placed on a stable, level surface to minimize vibration.

- Sample Size: Avoid overloading the bag, as large samples can cause imbalance and excessive noise.

- Maintenance: Regularly inspect and maintain the machine. Loose components can cause noise and should be tightened or replaced.

6. Difficulty in Extracting Samples

Issue:

Difficulty in retrieving the homogenized sample from the blending bag, leading to potential sample loss.

Troubleshooting Methods:

Bag Handling: Use appropriate tools (e.g., sterile pipettes or scoops) to extract the sample from the bag.

Bag Design: Consider using filter bags, which allow for easier separation of the homogenate from solid particles.

Technique: Gently massage the bag before opening to ensure the sample is fully mixed and easier to extract.

Effectively using a lab blender stomacher in microbiological analysis requires not only understanding its operation but also being prepared to address common issues that may arise. By implementing these troubleshooting methods, you can maintain the integrity of your samples and ensure reliable, accurate results in your microbiological analyses. Regular maintenance, proper sample preparation, and adherence to best practices are key to minimizing problems and maximizing the efficiency of your lab blender stomacher.

Summary

The lab blender stomacher is an indispensable tool in microbiological analysis, providing an efficient and reproducible method for homogenizing samples. Effective use involves careful preparation, precise operation, and diligent post-processing. By adhering to best practices and maintaining the equipment properly, researchers can ensure consistent and accurate results, enhancing the reliability of their microbiological analyses.