In laboratories and research facilities, precise measurement of melting points is crucial for characterizing various substances. However, this process comes with inherent risks if not conducted safely. This article aims to provide comprehensive guidance on using automatic melting point apparatus securely, ensuring both accurate results and personal safety.

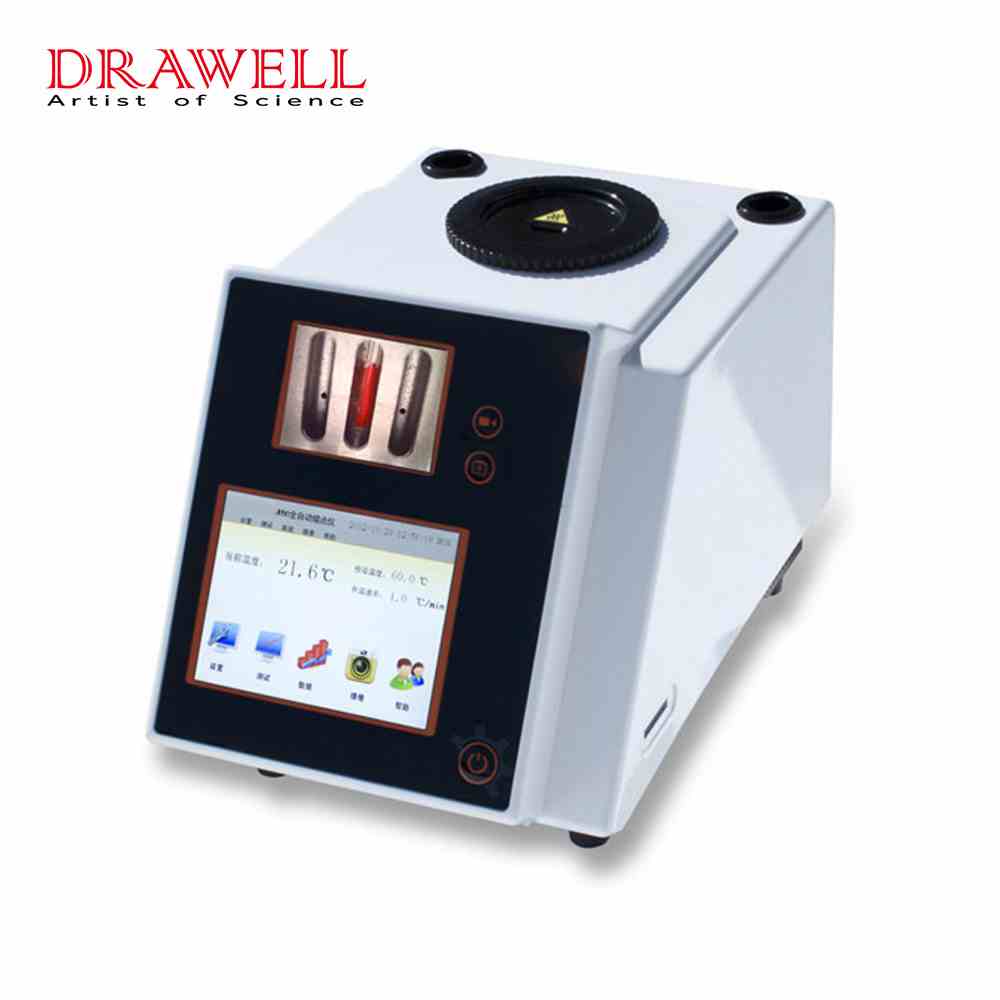

What are the Automatic Melting Point Apparatus?

Automatic melting point apparatus is a device used in laboratories to determine the melting point of a substance with high precision and accuracy. It offers automated temperature control and monitoring during the melting process, eliminating human error and providing consistent results.

Key components of an automatic melting point apparatus typically include:

- Heating Block: This is where the sample is placed for heating. It usually consists of a metal block with precise temperature control mechanisms.

- Heating Element: The heating element is responsible for generating heat to raise the temperature of the sample.

- Temperature Sensor: A sensor is used to monitor the temperature of the sample during the melting process. This data is typically displayed on a digital screen.

- Cooling System: Some apparatus may include a cooling system to rapidly cool the sample once it has reached its melting point.

- Digital Display: Most modern automatic melting point apparatus have a digital display that shows the current temperature and other relevant information.

- Automated Controls: These controls allow the user to set parameters such as the desired heating rate, temperature range, and cooling options. Once set, the apparatus operates automatically until the melting point is reached.

- Sample Holder: A mechanism for securely holding the sample, ensuring uniform heating and accurate temperature measurement.

- Safety Features: Automatic melting point apparatus may include safety features such as overheating protection to prevent damage to the device or the sample.

Overall, automatic melting point apparatuses streamline the process of determining the melting point of a substance, making it faster, more reliable, and easier for researchers and analysts in various fields such as chemistry, pharmaceuticals, and materials science.

Safety Precautions When Using Automatic Melting Point Apparatus

When using an automatic melting point apparatus, it’s important to follow safety precautions to prevent accidents and ensure accurate results. Here are some common safety measures:

Before Operation:

- Read the Manual: Familiarize yourself with the operation and safety guidelines provided by the manufacturer in the user manual.

- Inspect the Apparatus: Check for any visible damage or defects in the apparatus. Ensure that all components are in good working condition.

- Wear Personal Protective Equipment (PPE): Wear appropriate PPE such as lab coat, safety goggles, and heat-resistant gloves to protect yourself from potential hazards.

- Prepare the Workspace: Ensure that the workspace is clean, well-ventilated, and free from clutter. Remove any flammable materials or sources of ignition from the vicinity of the apparatus.

- Power Connection: Ensure that the apparatus is properly grounded and connected to a stable power source to prevent electrical hazards.

Sample Preparation Before Operation

When preparing samples for use in an automatic melting point apparatus, it’s crucial to follow specific precautions to ensure accurate and reliable results. Here’s a guide to sample preparation with safety in mind:

- Use High-Quality Samples: Ensure that the samples you are using are of high purity and quality. Impurities or contaminants can affect the melting point and lead to inaccurate results.

- Handle Samples Carefully: Handle samples with care to prevent contamination and minimize the risk of spills or accidents. Use clean, dry utensils and avoid touching the sample with bare hands to prevent introducing oils or other substances.

- Label Samples Clearly: Clearly label each sample with relevant information such as its identity, batch number, and any other pertinent details. This helps prevent mix-ups and ensures accurate record-keeping.

- Weigh Samples Accurately: Use an accurate balance or scale to weigh out the desired amount of sample. Ensure that the sample is evenly distributed and free from clumps or aggregates to ensure consistent melting behavior.

- Avoid Overfilling Sample Containers: Do not overfill sample containers or capillaries beyond the recommended capacity. Overfilled samples can lead to uneven heating and inaccurate results.

- Clean Sample Containers: Ensure that sample containers, such as capillaries or melting point tubes, are clean and free from residues from previous experiments. Contaminated containers can affect the melting behavior of the sample.

- Consider Sample Solubility: If the sample is soluble in a particular solvent, ensure that it is completely dissolved before transferring it to the sample container. Insoluble particles can affect the accuracy of the melting point determination.

- Protect Samples from Moisture: Keep samples protected from moisture and humidity, as these can alter the melting behavior of certain substances. Store samples in a dry environment and minimize exposure to air when handling.

- Use Suitable Sample Containers: Select appropriate sample containers based on the nature of the sample and the requirements of the apparatus. For example, use capillaries for small, powdery samples and melting point tubes for larger samples or those with higher melting points.

- Handle Hazardous Samples Safely: If working with hazardous or toxic substances, take appropriate safety precautions as per laboratory protocols. Wear appropriate personal protective equipment and handle the samples in a fume hood if necessary.

By following these precautions, you can ensure that your sample preparation process is conducted safely and effectively, leading to reliable melting point determinations in an automatic melting point apparatus.

During Operation:

During the operation of an automatic melting point apparatus, several safety precautions must be observed:

- Follow Operating Instructions: Operate the apparatus according to the manufacturer’s instructions. Avoid making any modifications or adjustments that are not recommended by the manufacturer.

- Monitor Temperature: Keep a close eye on the temperature display throughout the operation. Avoid overheating the apparatus or the sample, as it can lead to damage or safety hazards.

- Avoid Contact with Hot Surfaces: Handle the apparatus with care, especially when it is heated. Avoid touching hot surfaces and use heat-resistant tools or gloves when necessary.

- Do Not Leave Unattended: Never leave the apparatus unattended while it is in operation. Stay vigilant and ready to respond to any emergencies that may arise.

- Emergency Procedures: Familiarize yourself with the emergency shutdown procedures in case of malfunction or overheating. Know the location of emergency exits and safety equipment in the laboratory.

Post-Operation:

After completing the melting point determination process, it is essential to follow proper post-operation safety procedures:

- Cool Down Period: Allow sufficient time for the apparatus to cool down before attempting to clean or perform maintenance tasks.

- Turn Off Power: Switch off the power supply to the apparatus once the operation is complete. Unplug the apparatus if it is not going to be used for an extended period.

- Clean and Maintain: Clean the apparatus regularly according to the manufacturer’s recommendations to prevent buildup of contaminants or residues. Keep the apparatus in good condition by performing routine maintenance checks.

- Store Properly: Store the apparatus in a dry, clean, and well-ventilated area when not in use. Avoid exposure to extreme temperatures or environmental conditions that could affect its performance.

- Report Any Issues: If you encounter any problems or safety concerns with the apparatus, report them to the appropriate personnel or supervisor immediately. Do not attempt to repair or troubleshoot the apparatus yourself unless you are qualified to do so.

By following these safety precautions, you can minimize the risks associated with using an automatic melting point apparatus and ensure a safe working environment in the laboratory.

Conclusion

Using an automatic melting point apparatus safely requires careful attention to detail and adherence to established safety protocols at every stage of operation. By following the guidelines outlined in this article, researchers and laboratory personnel can minimize risks, safeguard their well-being, and obtain accurate melting point measurements essential for their scientific endeavors. Feel free to contact us if you buy Drawell automatic melting point apparatus, we will provide you satisfied after-sale services.