Biosafety cabinets are used to protect the operator, the laboratory environment, and experimental materials from infectious aerosols and splash when operating infectious experimental materials such as primary cultures, bacterial strains, and diagnostic specimens. Biological safety cabinets are designed for harm to the laboratory environment and experimenters. Today, this article will introduce tips to buy biosafety cabinets and install biosafety cabinets.

How to Select Biosafety Cabinet?

When you buy a biosafety cabinet, the selection of an appropriate biosafety cabinet is mainly based on the following types of protection required:

- Protecting the experimental subjects with biosafety cabinets.

- Personal protection when handling pathogenic microorganisms with hazard degrees 1 to 4 by using biosafety cabinets

- Personal protection when exposed to radionuclides and volatile toxic chemicals.

- Different combinations of the various protections mentioned above.

When handling volatile or toxic chemicals, biosafety cabinets that recirculate air into the room should not be used. Class II Type B1 and Class II Type A2 (external piping) biosafety cabinets can be used to handle small amounts of volatile chemicals and radioactive nuclear substances or elements. Class II B2 type biosafety cabinets are also called full-discharge safety cabinets, which are suitable for handling a large number of radionuclides and a large number of volatile toxic chemicals. When extracting nucleic acids, such full-discharge biosafety cabinets should be selected to avoid cross-contamination to avoid molecular contamination.

How to Install Biosafety Cabinets?

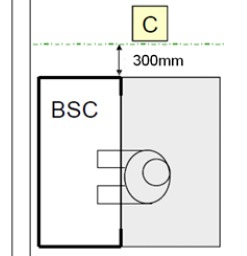

Air enters the biosafety cabinet through the front entrance at a rate of 0.38 to 0.5 ml/s. The directional airflow at such a speed is easily disturbed, and the airflow formed by people approaching the biosafety cabinet, the adjustment of the air supply system, and the opening and closing of doors and windows may cause. Therefore, it is ideal to install the biosafety cabinet away from personnel activities, article flow, and possible disturbed airflow. There should be a space of about 30cm behind the safety cabinet and on each side as much as possible, to facilitate the cleaning and maintenance of the safety cabinet. There should be a space of 30 to 35 cm above the safety cabinets to accurately measure the speed of the air passing through the exhaust filter and replace the exhaust filter.

The installation of biosafety cabinets is relatively strict, so they should be installed according to the regulations.

No matter what type of biosafety cabinets they are, they must be placed according to their air intake and exhaust requirements. Regarding the placement of biological safety cabinets, there are 5 basic away principles, the core of which is to stay away from airflow fluctuation points. It Includes doors, fans, air conditioners, open windows, and high-traffic areas.

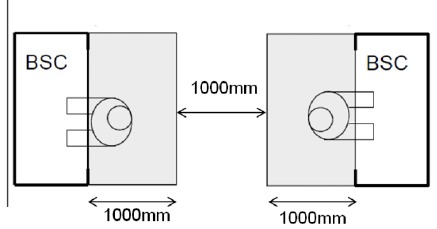

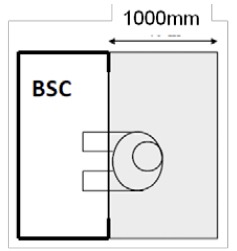

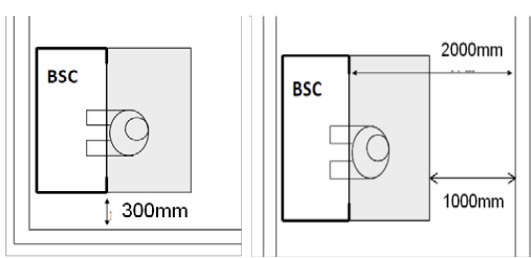

For the placed ground and surrounding dimensions, there are two basic requirements of biosafety cabinets:

- A stable platform or stand.

- Reserve 30cm on both sides, back, and top of the cabinet.

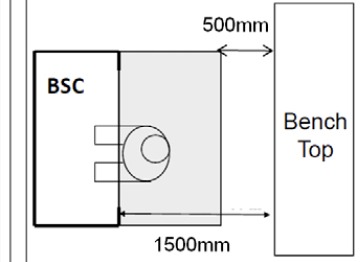

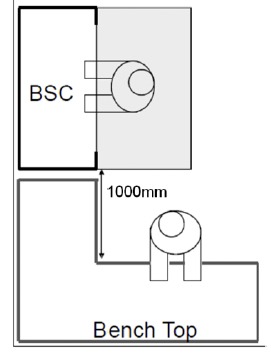

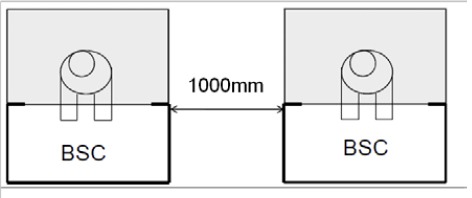

For different situations where safety cabinets are placed, the distance requirements are shown in a simplified diagram as follows:

- Schematic diagram of operating space

- Schematic diagram of distance from the wall

- Schematic diagram of the distance from the operating table

- Schematic diagram of distance from a side console

- Schematic diagram of the distance between columns

- Schematic diagram of side-by-side distance

- Schematic diagram of Back to back placement distance