Introduction of High Speed Benchtop Refrigerated Centrifuge

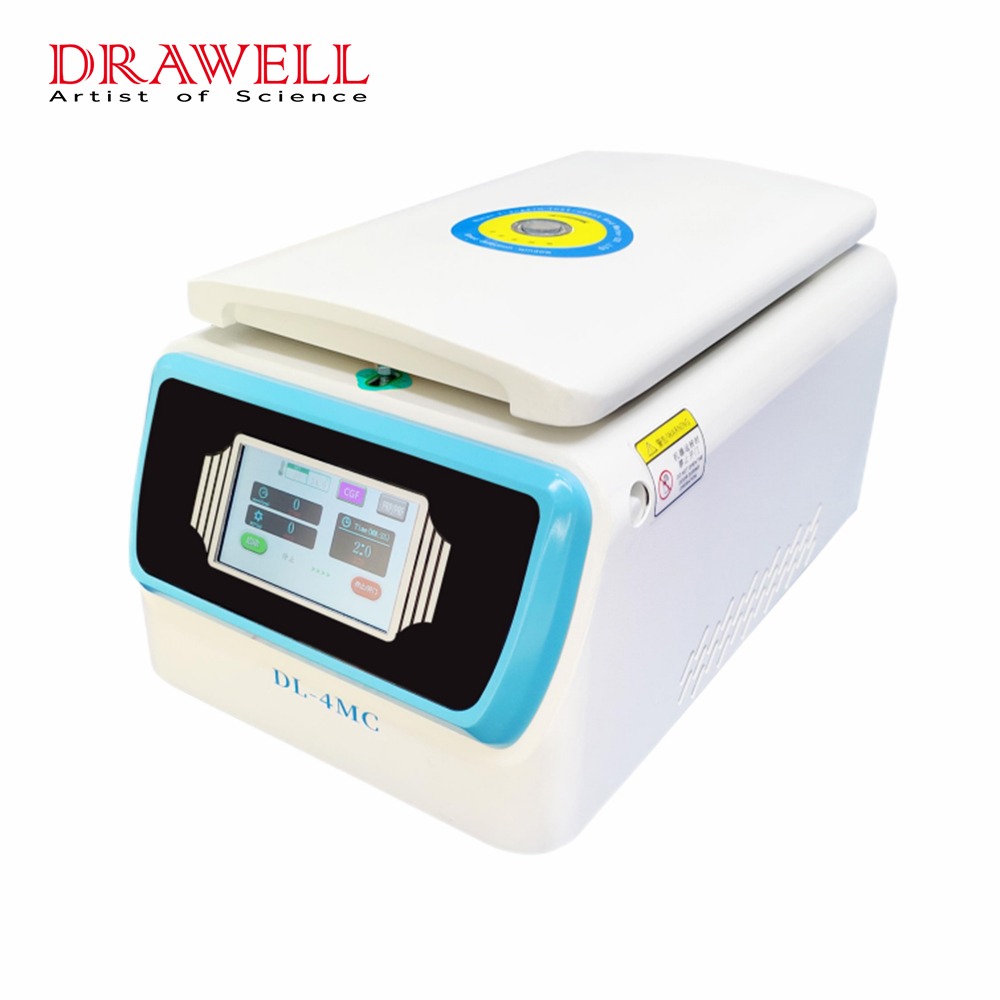

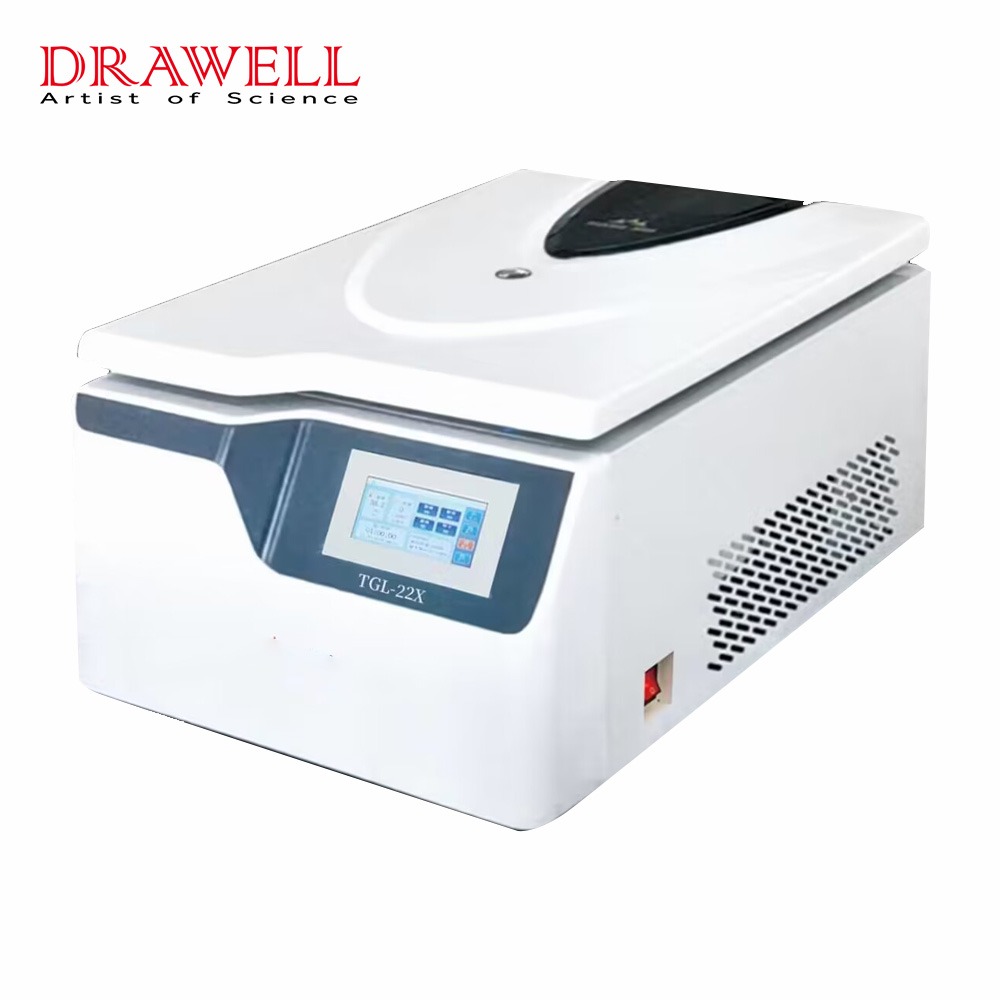

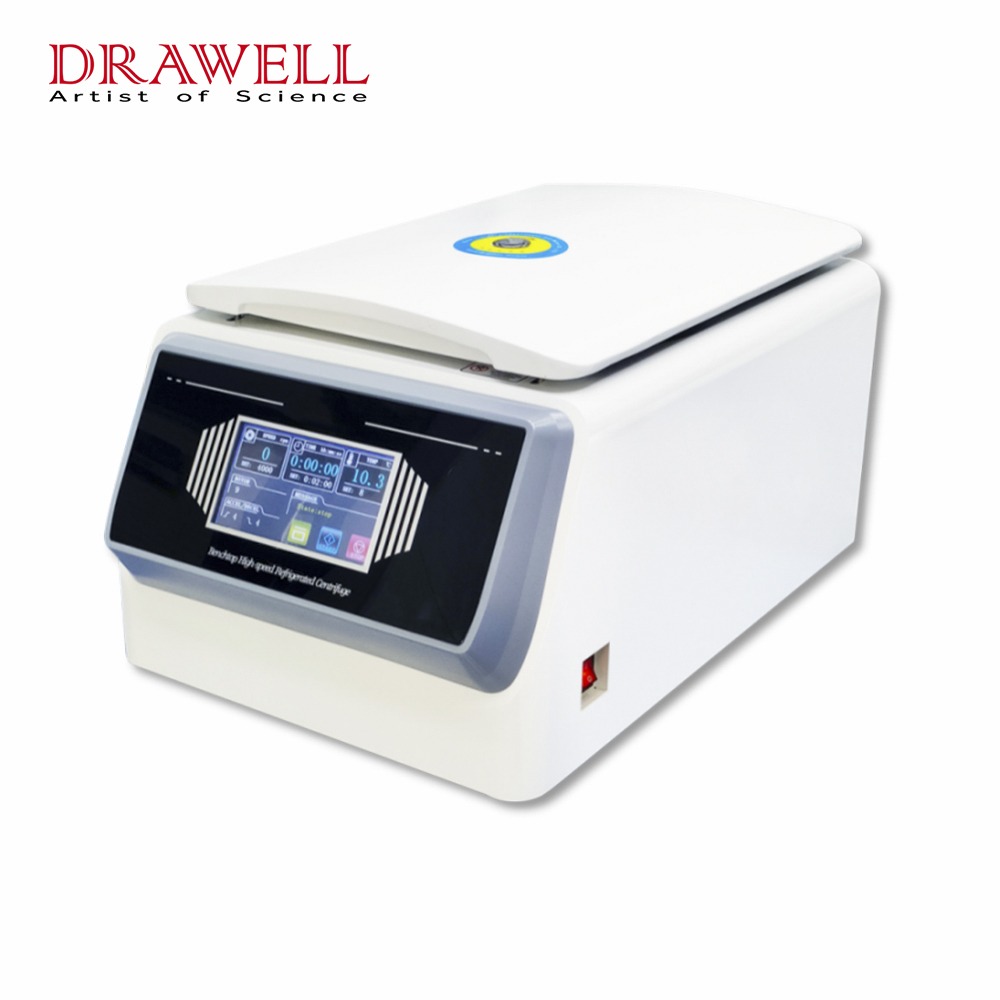

The high-speed benchtop refrigerated centrifuge is a device used for refrigerated centrifuge, which is an important tool for separation in the fields of medicine, life science, and agricultural science. This machine can be equipped with different kinds of rotors, which can largely meet the requirements of various scientific research experiments. In addition, it has high-quality compressors, motors, and rotors, which are low vibration and low noise. The maximum speed noise of a high-speed refrigerated centrifuge is less than 67dB. When it works normally, the normal working noise is lower than 62dB. In order to prolong the life of a high-speed benchtop refrigerated centrifuge, here are ten tips for the refrigerated benchtop centrifuge.

10 Tips for Maintaining a High-speed Benchtop Refrigerated Centrifuge

1. To prevent the rotor from sticking to the rotating shaft, or prevent the transmission shaft from bending due to static load for a long period of time, the rotor must be removed from the centrifuge after each use of the refrigerated centrifuge machine. If the machine has to work for a long time, please apply a layer of grease to the connection between the rotor and the rotating shaft before using the rotor.

2. Do not use sharp objects to collide with the rotor. Also, avoid shocks during transportation and disassembly and prevent cracks in the rotor during use due to scratches or trauma.

3. Periodically inspect the rotor parts, especially the inside of the centrifuge bowl. Check for corrosive spots, grooves, and small cracks. If any of the above conditions are found, stop using the rotor and contact the manufacturer.

4. Normally, the rotor and centrifuge cup are cleaned once a week. After separating saline solutions or other corrosive samples, the benchtop high-speed refrigerated centrifuge should be cleaned immediately. If the sample has splashed, soaked, or dripped onto the rotor during use, it should be immediately vacuumed dry and cleaned on site.

5. In order to prevent the surface oxide layer from being damaged when cleaning the rotor, apply the cleaning agent to a sponge or cotton cloth. Then wash off the cleaning agent with distilled water or rub it off with 70% olein. Do not spray or splash the rotor with water, as the liquid could get caught somewhere and cause. When cleaning the centrifuge cup, pay special attention to the grooves on both sides, and allow it to dry upside down after cleaning.

6. Immediately remove frost and moisture in the chamber.

7. The dust on the condenser radiator must be removed every three months.

8. After replacing the belt, you should turn the belt of the motor clockwise by hand several times to check the balance of the running stagnation balance and to see if the belt is twisted and slipping. Once you have determined this, you can install the rotor for a test run.

9. Before removing the side panel of the high-speed benchtop refrigerated centrifuge, first, disconnect the power supply, and live operation is not allowed to protect the operator from electric shock or damage to the machine.

10. Turn off the power supply when the centrifuge is not in use.

Conclusion

In a word, you can maintain a high-speed benchtop refrigerated centrifuge using the above methods. If the above methods can not help you, you need to contact the manufacturer or supplier of a high-speed benchtop refrigerated centrifuge.