The Kjeldahl nitrogen analyzers are widely used in laboratories for analyzing nitrogen content in various samples, particularly in food, agricultural, and environmental studies. However, measuring low-nitrogen samples poses unique challenges that demand innovative solutions to enhance precision and accuracy. This article explores the key strategies and technologies that can improve the performance of Kjeldahl nitrogen analyzers when dealing with low-nitrogen samples.

Challenges of Low-Nitrogen Sample Analysis Using Kjeldahl Nitrogen Analyzers

1. Low Signal-to-noise Ratio

Analyzing low-nitrogen samples using Kjeldahl nitrogen analyzers comes with unique hurdles. One primary challenge is the low signal-to-noise ratio, where the nitrogen concentration is so close to the detection limit that background interference can significantly affect precision. This makes it difficult to differentiate between actual nitrogen content and noise in the analytical system.

2. Contamination Risks

Another significant issue is the heightened susceptibility to contamination. Even minor traces of nitrogen from reagents, glassware, or environmental factors can skew results, making it challenging to obtain accurate measurements. Proper cleaning protocols and the use of high-purity reagents are essential, yet these measures often add complexity to the process.

3. Sensitivity of Detection

Moreover, the sensitivity of traditional Kjeldahl systems may not always be sufficient for low-nitrogen content. Older analyzers might struggle to detect and quantify nitrogen accurately at such minimal levels, necessitating the adoption of advanced technologies or modifications to existing methods. These challenges demand innovative approaches to ensure reliability and precision in low-nitrogen analyses.

Strategies to Enhance Precision of Kjeldahl Nitrogen Analyzer for Low-Nitrogen Samples

1. Optimizing Sample Preparation

Using larger sample sizes is a simple yet effective approach to amplify the nitrogen signal. This ensures better detection accuracy. Additionally, employing high-purity reagents minimizes background noise and reduces the risk of contamination that could compromise the results.

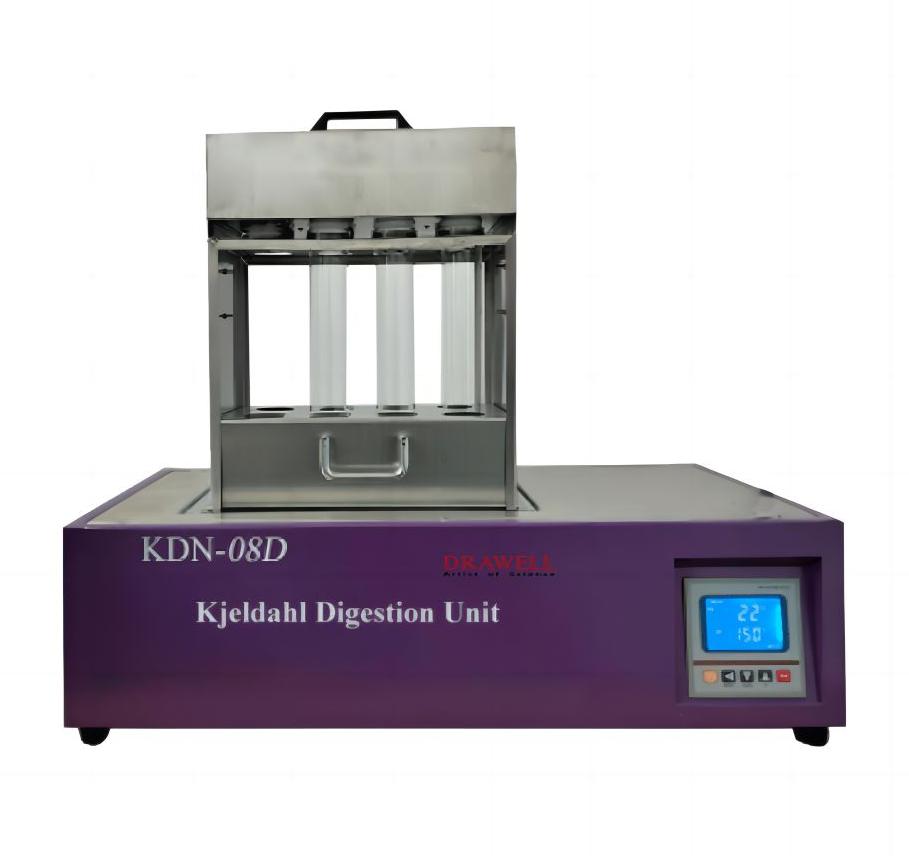

2. Advancing Digestion Techniques

Uniform digestion is critical when working with low-nitrogen samples. Efficient heating systems with precise temperature controls in digestion furnace ensure consistent results. Moreover, selecting optimized catalyst blends can speed up the digestion process while minimizing interference from external contaminants.

3. Upgrading Detection and Titration Systems

Automated titration systems equipped with micro-titration capabilities significantly reduce human error, improving endpoint detection accuracy. Advanced detection methods, such as colorimetric or potentiometric sensors, are particularly valuable for enhancing sensitivity when working with minimal nitrogen concentrations.

4. Minimizing Environmental Contamination

Maintaining a clean workspace is crucial. Analytical processes should be conducted in isolated environments to prevent airborne nitrogen contamination. Regular calibration of the equipment using low-nitrogen standards further ensures consistent and accurate results.

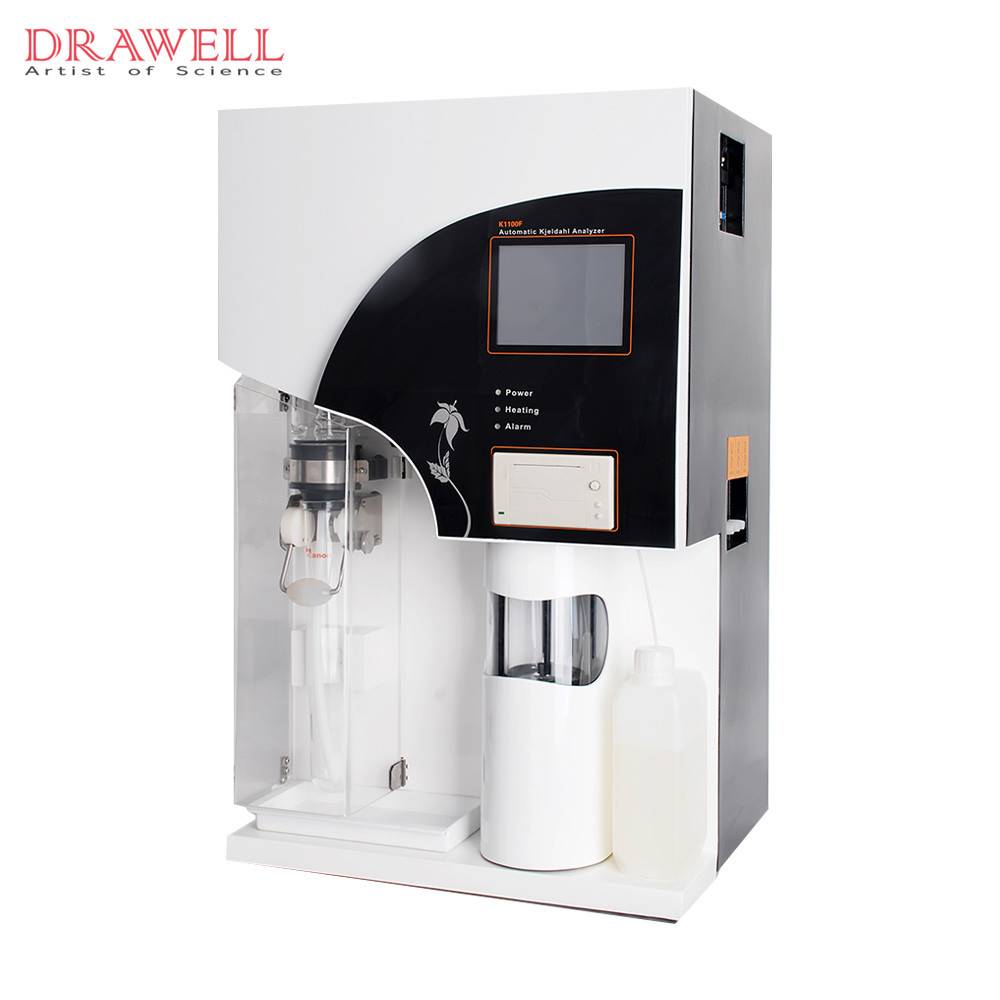

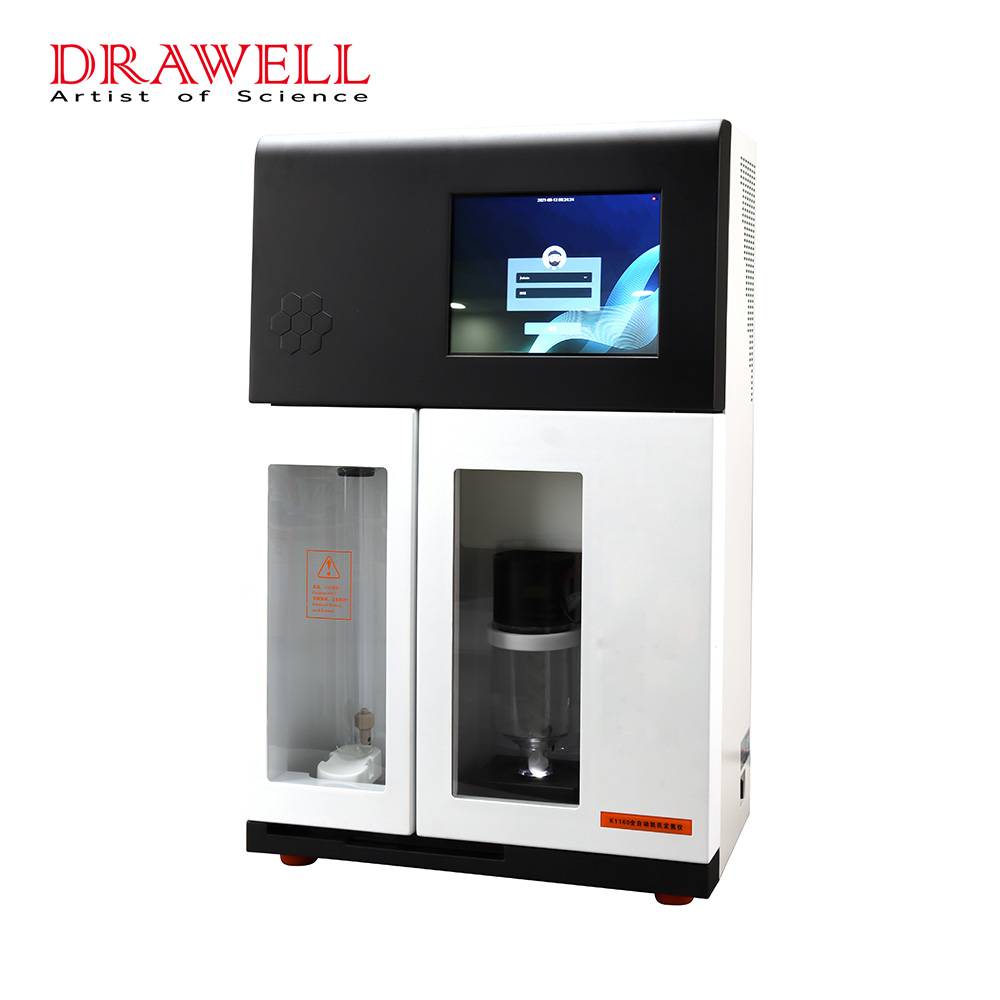

5. Adopting Modern Features in Kjeldahl Systems

Advanced Kjeldahl nitrogen analyzers often come with high-sensitivity sensors designed to detect trace nitrogen levels. These systems, when integrated with digital data analysis and monitoring software, provide precise control and facilitate real-time adjustments, ensuring better outcomes in low-nitrogen applications.

Technological Innovations in Kjeldahl Nitrogen Analyzer for Low-Nitrogen Samples

- Micro-Digestion Systems

Modern Kjeldahl analyzers now feature micro-digestion units that require smaller reagent volumes while ensuring thorough and efficient digestion. These systems are particularly beneficial for low-nitrogen analysis, as they reduce contamination risks and improve reaction consistency.

- High-Sensitivity Detection Methods

Advanced analyzers incorporate highly sensitive sensors, such as colorimetric or potentiometric detectors, to precisely measure nitrogen levels, even in trace amounts. These technologies enhance the signal-to-noise ratio, allowing for accurate detection in low-concentration samples.

- Automated Titration Systems

Automated Kjeldahl analyzers with titration units ensure precise endpoint detection by minimizing manual intervention. These systems often use micro-titration capabilities to achieve unparalleled accuracy, particularly in low-nitrogen content analysis.

- Enhanced Heating and Digestion Control

Enhanced heating systems with precise temperature regulation guarantee uniform digestion across samples, which is critical when dealing with low concentrations of nitrogen. Additionally, smart monitoring systems and real-time digital integration have made it possible to track every stage of the analysis process. These technologies allow laboratories to identify anomalies, adjust parameters in real-time, and perform comprehensive data analysis to ensure consistent and reproducible results.

- Real-Time Monitoring and Digital Integration

Many Kjeldahl analyzers now feature smart monitoring systems that provide real-time data on digestion, distillation, and titration processes. Coupled with digital analysis software, these tools enable trend analysis, anomaly detection, and automatic parameter adjustments, ensuring consistent results.

- Contamination-Resistant Components

To address the challenges of low-nitrogen sample analysis, manufacturers have introduced contamination-resistant glassware, tubing, and reagent systems. These components minimize external interference, leading to more accurate results.

- Compact and Eco-Friendly Designs

Some modern analyzers have been designed to be compact and energy-efficient. By using smaller amounts of reagents and producing less waste, these systems align with green laboratory practices while maintaining high precision.

Applications of Kjeldahl Nitrogen Analyzers with Enhanced Precision in Low-Nitrogen Sample Analysis

This chart demonstrates the broad applicability of enhanced Kjeldahl nitrogen analyzers in industries and fields where precision in low-nitrogen sample analysis is essential.

| Application Area | Examples | Significance |

| Agriculture and Soil Science | Fertilizer testing, soil nitrogen content analysis | Enables precise measurement of trace nitrogen, aiding in optimal crop nutrition and soil management. |

| Food and Beverage Industry | Protein analysis in low-protein foods, water testing in beverages | Ensures accurate labeling of low-protein products and compliance with quality standards. |

| Pharmaceutical Research | Nitrogen analysis in drug formulations, trace nutrient content verification | Facilitates precise formulation and regulatory compliance for pharmaceutical products. |

| Environmental Monitoring | Water and wastewater testing, atmospheric nitrogen content analysis | Provides accurate data for pollution control and regulatory reporting of environmental samples. |

| Industrial Applications | Polymer production, industrial effluent analysis | Enhances quality control and minimizes environmental impact by monitoring trace nitrogen. |

| Academic and Scientific Research | Studies on nitrogen cycling, nutrient dynamics in ecosystems | Supports high-precision research in ecological and biochemical studies involving low nitrogen levels. |

Final Thoughts

Enhancing the precision of Kjeldahl nitrogen analyzers in low-nitrogen samples requires a combination of optimized sample preparation, advanced detection methods and the integration of modern technology. By addressing these challenges, laboratories can achieve reliable results even when working with trace levels of nitrogen.