Bromides, which include a range of organic and inorganic salts, often have well-defined melting points that can be used to confirm their identity and assess their purity. This article will guide you through the process of determining the melting point of bromide samples using both manual and automated techniques.

Understanding the Importance of Melting Point Determination in Bromide Samples

This chart highlights the critical reasons why melting point determination is vital for analyzing and working with bromide samples, emphasizing its role in identification, purity assessment, quality control, and more.

| Aspect | Description | Importance |

| Identification | Melting point is a characteristic physical property of bromide compounds. | Helps in confirming the identity of a bromide compound by comparing its melting point with known values. |

| Purity Assessment | Pure compounds have a sharp, well-defined melting point, while impurities cause melting point depression and broadening. | Indicates the purity of the bromide sample; a narrow melting point range suggests high purity. |

| Quality Control | Regular melting point checks are part of quality control processes in industrial and laboratory settings. | Ensures consistency and reliability in the production and handling of bromide compounds. |

| Comparison with Literature Values | Melting point can be compared with standard reference values for specific bromide compounds. | Facilitates verification against standard references to ensure correct formulation and synthesis of bromides. |

| Thermal Stability Analysis | Monitoring melting point under varying conditions can indicate the thermal stability of bromide samples. | Helps in determining the suitability of bromide compounds for various applications, particularly those involving heat. |

| Characterization of New Compounds | Determining the melting point is essential when synthesizing or isolating new bromide compounds. | Provides foundational data for the characterization and documentation of new bromide compounds. |

Preparing Bromide Samples

Before measuring the melting point, ensure that your bromide sample is adequately prepared.

- Purity: The sample should be free of impurities, as contaminants can alter the melting point.

- Grinding: If the bromide is crystalline, grind it into a fine powder to ensure uniform heating.

- Drying: Make sure the sample is dry, as moisture can affect the melting process.

Manual Melting Point Determination Methods in Bromide Samples

1. Capillary Method

Equipment Needed: Capillary tubes, a thermometer, a heating apparatus (like a Thiele tube or oil bath), and a magnifying lens.

Procedure

- Fill a capillary tube with the bromide sample, ensuring that the sample is compacted at the bottom of the tube.

- Attach the capillary tube to a thermometer using a rubber band or clip.

- Immerse the thermometer and capillary tube in the heating apparatus, ensuring the sample is fully submerged.

- Slowly heat the apparatus while closely observing the sample through the magnifying lens.

- Record the temperature at which the sample starts to liquefy and the temperature at which it is completely melted. The range between these temperatures represents the melting point.

2. Hot Stage Microscopy

Equipment Needed: A microscope with a hot stage, thermometer, and a heat source.

Procedure

- Place a small amount of the bromide sample on the microscope’s hot stage.

- Gradually heat the stage while observing the sample through the microscope.

- Record the temperature at which the first sign of melting occurs and when the sample is fully liquefied.

Key Automated Melting Point Determination Methods in Bromide Samples

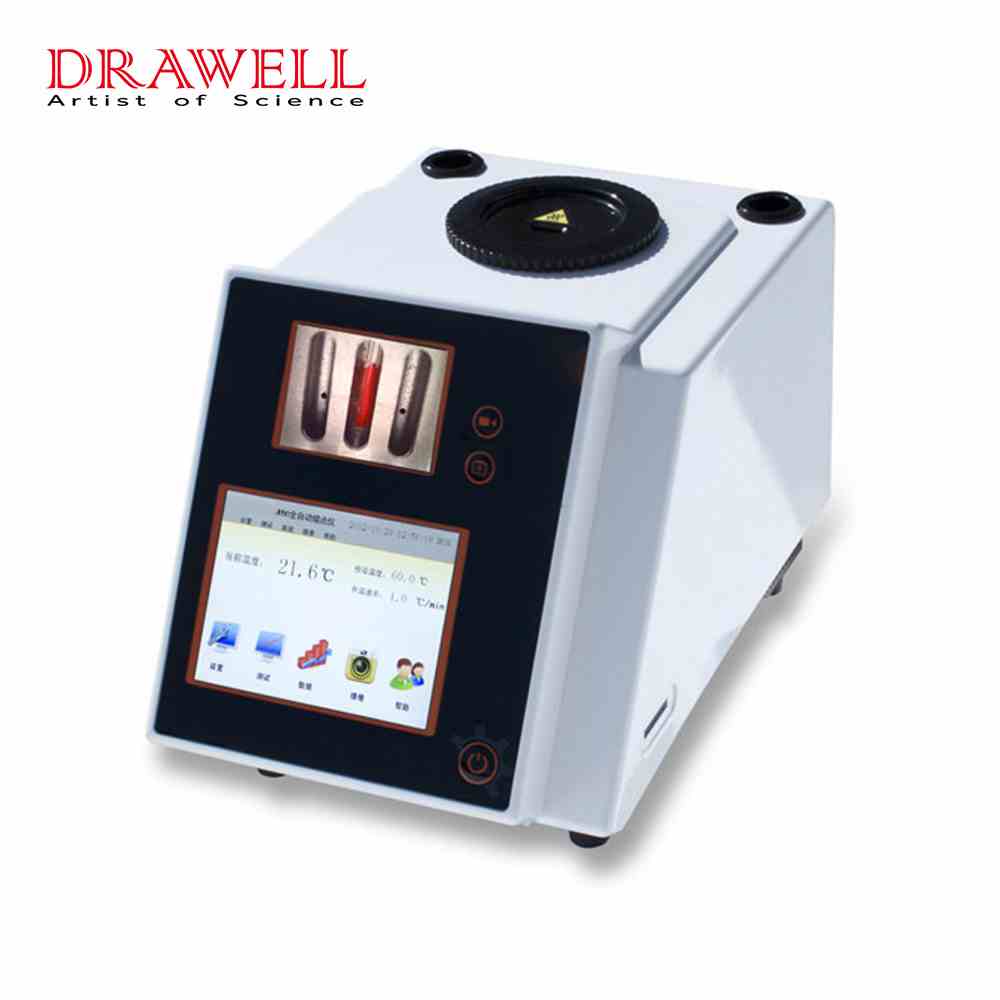

1. Automatic Melting Point Meters

Automatic melting point meters are compact and user-friendly instruments designed to automatically detect the melting point of a substance. They are equipped with a digital display, automated heating controls, and sensors that precisely determine when a sample starts and finishes melting.

Procedure

- Sample Preparation: Load the finely powdered bromide sample into a capillary tube.

- Insertion: Place the capillary tube into the designated slot in the melting point meter.

- Programming: Set the desired heating rate and other parameters on the device’s interface.

- Automatic Measurement: The device will automatically heat the sample at the programmed rate, detect the onset and end of melting, and display the melting point on the digital screen.

Advantages

- High Precision: Digital sensors and automated controls ensure accurate detection of melting points.

- Ease of Use: Simple programming and automated processes make these meters accessible for users at all skill levels.

- Quick Results: Automated systems provide faster results compared to manual methods.

2. Advanced Melting Point Apparatus with Photometric Detection

Advanced automatic melting point apparatuses often incorporate photometric detection to enhance the accuracy of melting point determination. These systems use light transmission or reflection to detect changes in the physical state of the sample, providing precise measurements.

Procedure

- Sample Loading: Place the bromide sample in a capillary tube and insert it into the instrument.

- Heating Process: The apparatus will gradually heat the sample while a light beam passes through or reflects off the sample.

- Detection: As the sample melts, the light transmission or reflection changes, which is detected by the instrument’s sensors.

- Data Output: The melting point is calculated based on these changes and displayed digitally.

Advantages

- Increased Accuracy: Photometric detection reduces the risk of human error and provides highly accurate melting point readings.

- Comprehensive Data: Some models offer detailed graphical representations of the melting process, which can be useful for more in-depth analysis.

3. Automated Multi-Sample Melting Point Systems

For laboratories that need to analyze multiple samples simultaneously, automated multi-sample melting point systems are ideal. These systems can process several samples at once, significantly increasing throughput.

Procedure

- Sample Loading: Prepare multiple bromide samples and load them into the system’s sample holders.

- Automated Operation: The system will heat each sample in parallel, using individual sensors to monitor the melting points of each sample.

- Batch Analysis: Results for all samples are recorded and displayed, allowing for easy comparison and analysis.

Advantages

- High Throughput: Multiple samples can be analyzed simultaneously, saving time and resources.

- Consistency: Automated systems ensure consistent heating and measurement across all samples.

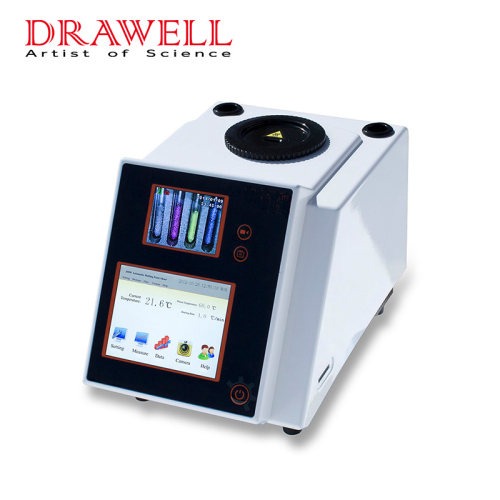

4. Automatic Image Processing in Melting Point Determination

Some advanced automatic video melting point detection meters utilize digital image processing to capture real-time images of the sample during the heating process. This method allows for a detailed analysis of the melting behavior of bromide samples.

Procedure

- Sample Placement: The bromide sample is placed in a transparent capillary tube.

- Imaging: The system captures images of the sample as it heats, using software to analyze changes in the sample’s appearance.

- Analysis: The system detects the melting point based on visual cues and changes in the sample’s structure.

- Output: The melting point is displayed along with a visual record of the melting process.

Advantages

- Visual Documentation: Provides a visual record of the melting process, which can be useful for further analysis and documentation.

- Enhanced Detection: Image processing can detect subtle changes that may not be captured by other methods.

Accurate determination of the melting point offers valuable insights into the purity and identity of the bromide compound. This information is critical for both research and quality control in various industrial and laboratory settings. Automated melting point detection methods offer significant advantages over traditional manual techniques, which provide high precision, repeatability, and efficiency, making them essential tools in modern laboratories.