Elemental analysis is a crucial technique in various scientific fields, including chemistry, environmental science, materials science, and pharmaceuticals. It involves determining the elemental composition of a substance, providing valuable insights into its chemical structure, purity, and properties. With a wide array of elemental analyzers available, selecting the right instrument for specific research or industrial needs can be challenging. Here we outlines the key factors to consider and provides actionable steps to help you make an informed decision.

Key Factors to Consider

Choosing the right elemental analyzer involves evaluating multiple critical aspects to ensure the instrument meets your specific needs. From the elements to be analyzed to the level of vendor support, each factor contributes to the overall effectiveness and suitability of the analyzer. By carefully assessing these key considerations, you can streamline the selection process and avoid costly mismatches.

1. Elements to be Analyzed

The first and foremost consideration is the specific elements of interest. Different analyzers are designed to measure different elements.

Types of Analyzers:

- CHNS/O Analyzers: Ideal for organic materials, measuring carbon, hydrogen, nitrogen, sulfur, and oxygen.

- Trace Element Analyzers: Suitable for detecting low concentrations of elements in complex matrices.

- Halogen Analyzers: Designed for elements like chlorine, bromine, and fluorine.

- Spectroscopy-Based Analyzers: Useful for metals, minerals, and a broad range of elements.

- Specific Element Analyzers: These are designed for the analysis of a single element, such as dedicated sulfur analyzers used in the petrochemical industry or chlorine analyzers for environmental applications.

2. Sample Type and Size

The nature and size of the samples to be analyzed significantly influence the efficiency of the analysis process.

- Solid Analyzers: These are designed for analyzing solid samples, such as organic compounds, polymers, environmental samples (soil, sediments), and geological materials.

- Liquid Analyzers: These are used for analyzing liquid samples, including oils, solvents, pharmaceuticals, and biological fluids.

- Gas Analyzers: These are specialized for analyzing gaseous samples, such as industrial emissions, atmospheric gases, and natural gas.

Furthermore, consider the typical sample size.

- Macro Analyzers: Suitable for relatively large samples (milligrams to grams).

- Micro Analyzers: Designed for smaller samples (micrograms to milligrams).

- Ultramicro Analyzers: Capable of analyzing extremely small samples (nanograms to micrograms), valuable for precious samples or trace element analysis.

Choosing an analyzer compatible with the sample type and size range ensures efficient and accurate analysis while minimizing sample preparation time and potential sample loss.

3. Analytical Technique

Analytical techniques vary based on application and precision requirements. Each technique has its strengths, limitations, and specific use cases.

Types of Techniques:

- Combustion Method: This technique involves burning the sample at high temperatures to break it down into its elemental components. The gases released (e.g., CO2, H2O, NOx, SOx) are measured to determine the composition. Such as CHNS/O analyzer for organic materials.

- Ion Detection Method: This approach uses ionization techniques to detect and quantify elements, particularly in gases or liquids. The sample is ionized, and the ions are separated and measured. Such as ICP-MS, offering high sensitivity for trace metal detection.

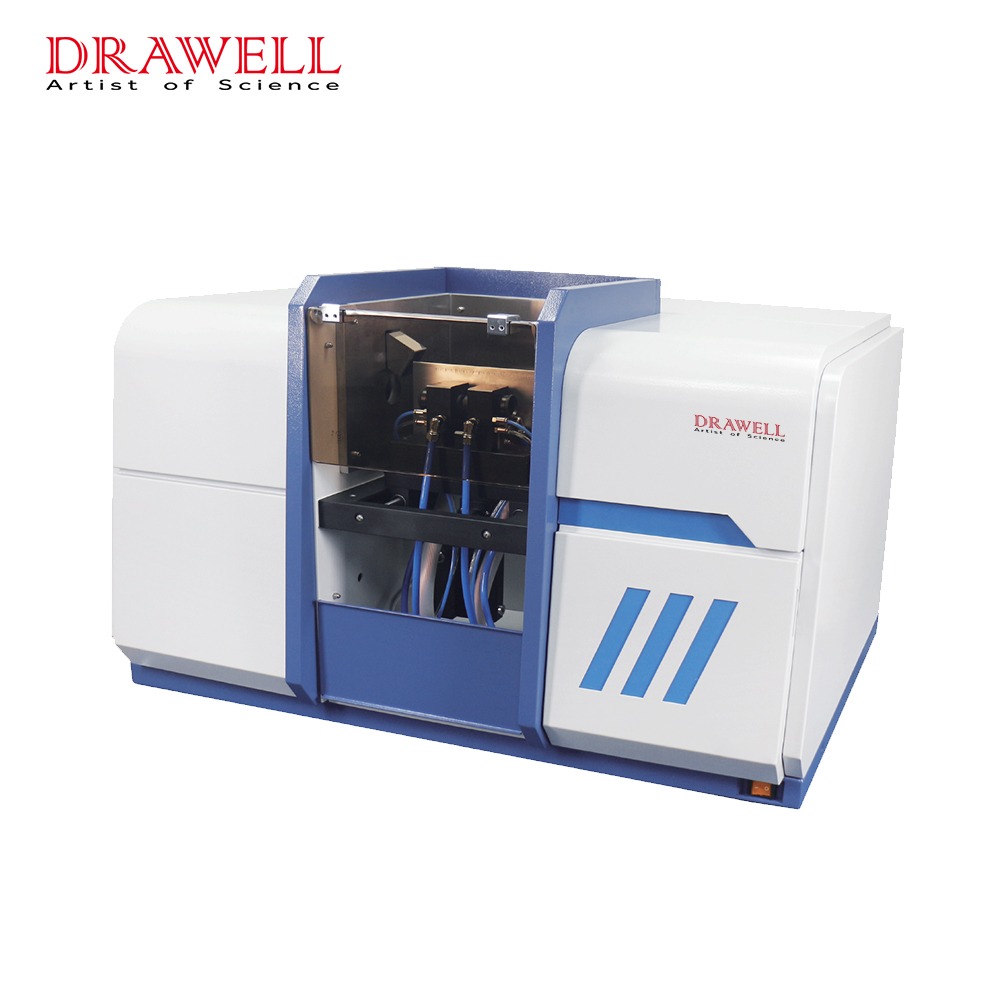

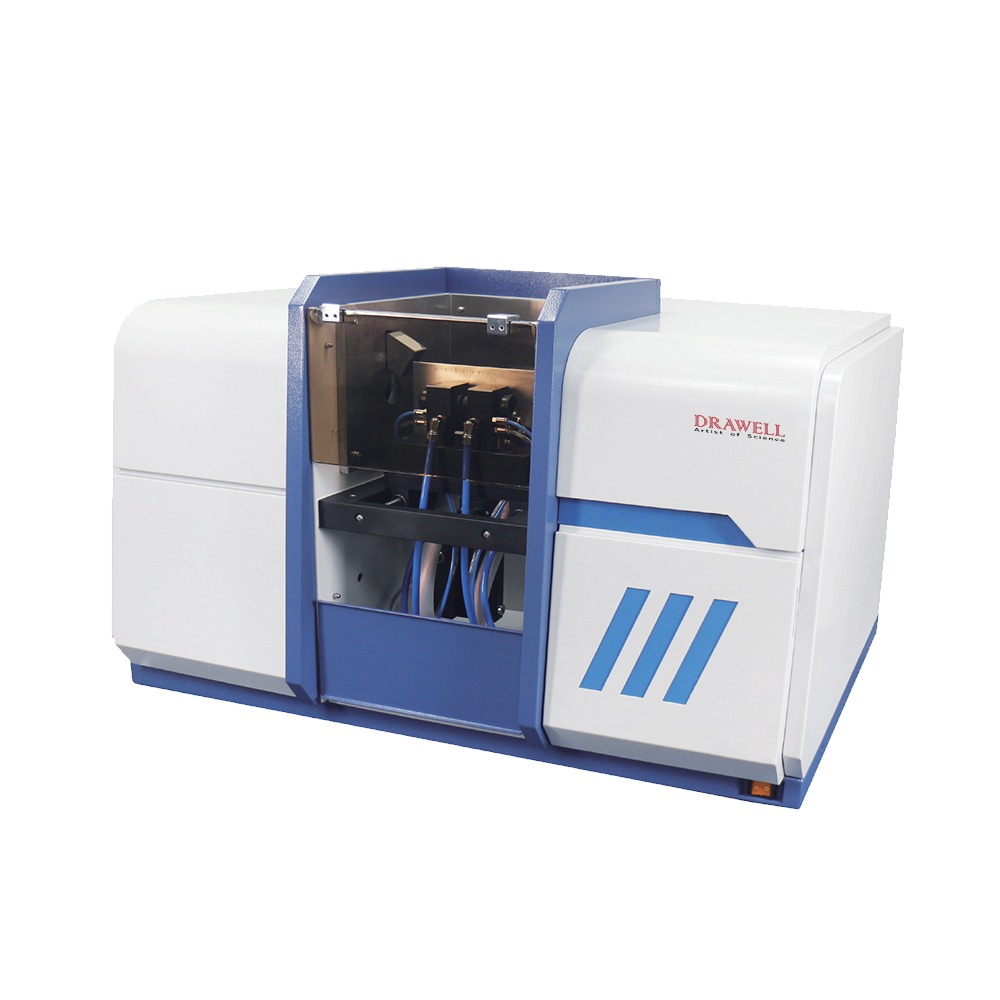

- Atomic Absorption Spectrometry (AAS): AAS measures the absorption of light by atoms in the gas phase, commonly used for detecting metals in liquid samples.

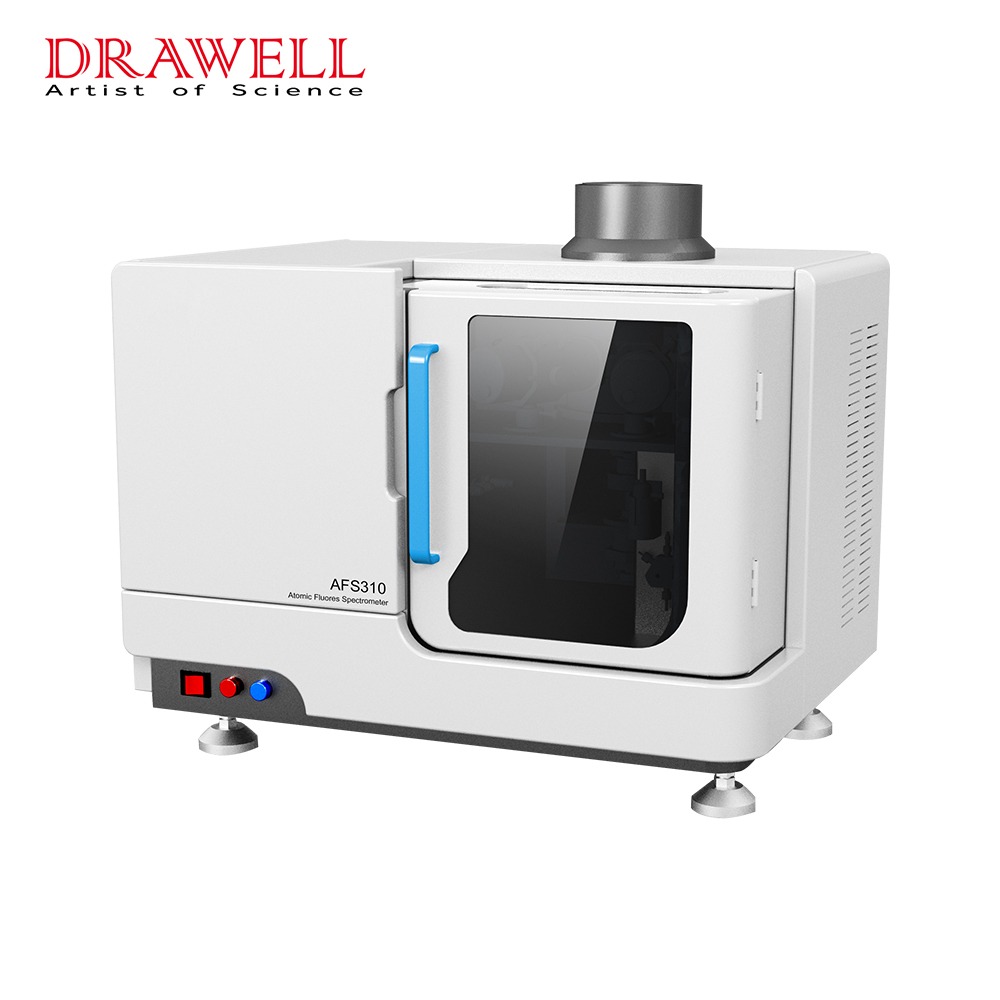

- Atomic Fluorescence Spectrometry (AFS): This technique measures the fluorescence emitted by atoms excited by a light source, often used for trace element analysis like mercury.

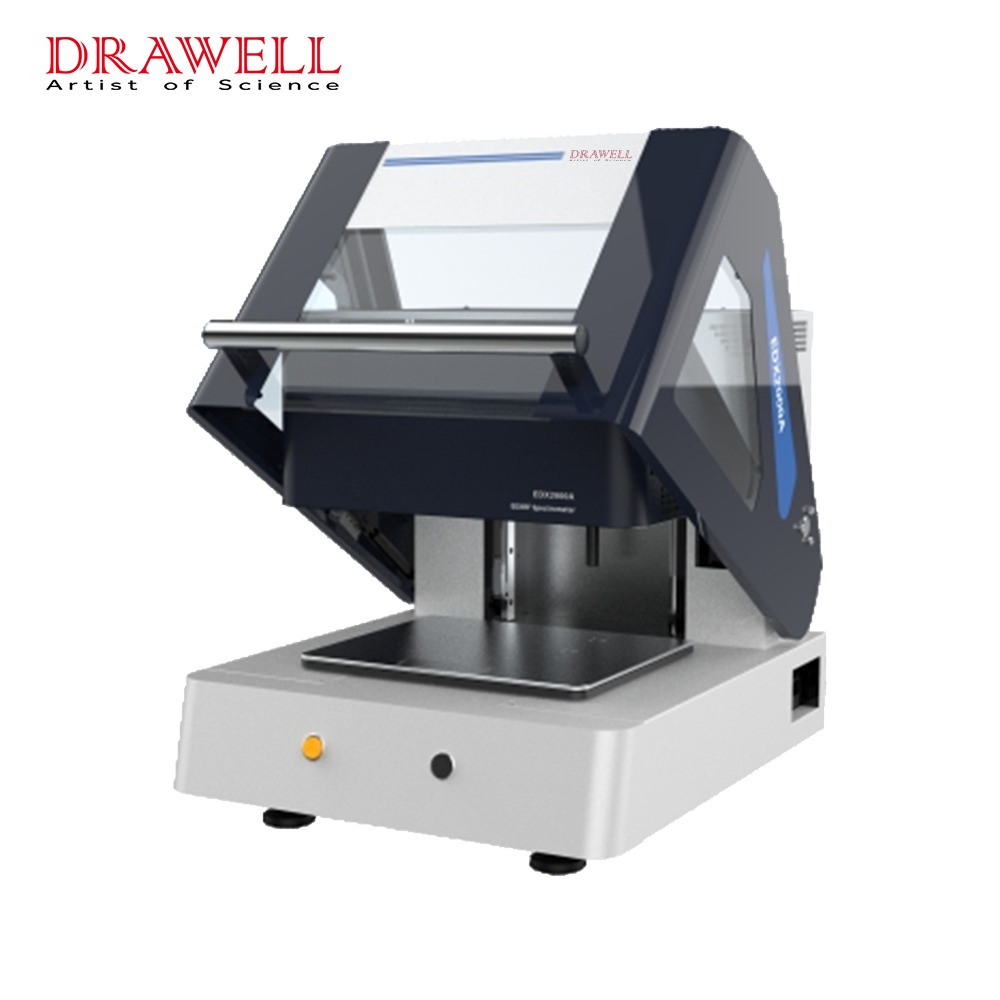

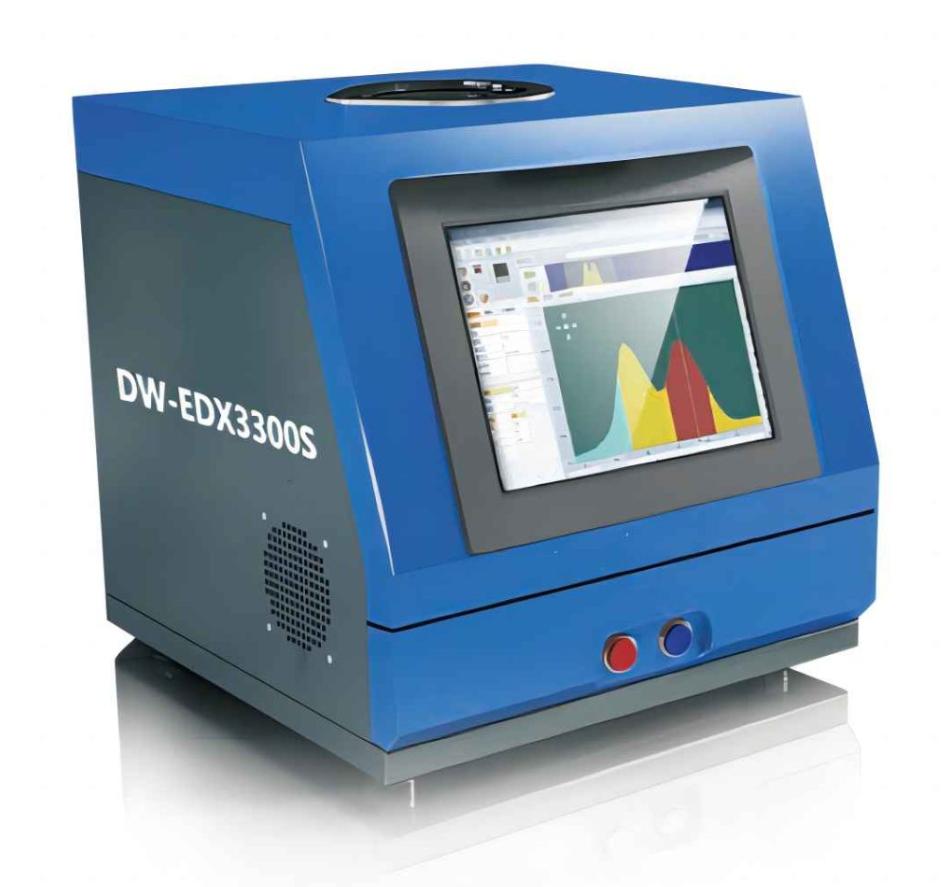

- X-Ray Fluorescence (XRF): XRF involves bombarding a sample with high-energy X-rays to excite atoms, causing them to emit secondary X-rays. These emissions are analyzed to identify and quantify elements in the sample. XRF is widely used for non-destructive analysis of metals, minerals, and industrial materials.

Select a technique that aligns with the material type, accuracy requirements, and regulatory standards specific to your application.

4. Required Sensitivity and Accuracy

Sensitivity and accuracy are critical for applications where small errors can have significant consequences.

- Sensitivity: Refers to the ability of the analyzer to detect and quantify low concentrations of elements. High sensitivity is critical for trace element analysis and environmental applications.

- Accuracy: Represents the closeness of the measured value to the true value. Accurate results are essential for reliable data interpretation and decision-making.

The required sensitivity and accuracy will depend on the specific application. For example, environmental monitoring may require high sensitivity to detect trace contaminants, while quality control in the pharmaceutical industry demands high accuracy for ensuring product safety and efficacy.

5. Sample Throughput and Automation

Consider the required sample throughput and the desired level of automation:

- High-throughput applications: May require automated sample handling systems, including auto-samplers and robotic arms, to increase efficiency and minimize labor costs.

- Manual Analyzers: Suitable for lower-throughput applications or situations where manual intervention is preferred.

Automation can significantly improve productivity and reduce the risk of human error. Evaluate the level of automation required to meet the specific needs of the laboratory and the available resources.

6. Budget and Cost of Ownership

Budget constraints often influence decision-making, but the total cost of ownership should also be considered.

- Initial Purchase Cost: Analyzers can range from relatively affordable benchtop models to highly sophisticated and expensive systems.

- Cost of Ownership: Consider ongoing costs, including consumables (reagents, gases, standards), maintenance, and service contracts.

Opt for an analyzer that balances performance and affordability, considering both upfront and long-term costs.

7. Vendor Support and Service

Reliable vendor support is crucial for ensuring the long-term success of the investment. Choose a vendor that provides excellent training, responsive technical support, and a comprehensive service network.

- Training and Support: Consider the availability of training programs, technical support, and application assistance from the vendor.

- Service Contracts: Evaluate the options for service contracts, including preventive maintenance, on-site service, and emergency repair services.

By addressing these key factors, you can simplify the selection process and choose an elemental analyzer that best fits your specific analytical needs.

Choosing the Right Analyzer

Selecting the right elemental analyzer requires balancing technical capabilities, industry requirements, and future adaptability.

Matching the Analyzer to Your Industry

Industries have unique requirements for elemental analysis. Aligning the analyzer’s capabilities with your industry ensures optimal performance. Such as:

- Pharmaceutical Industry: Requires high accuracy and precision for quality control, impurity analysis, and drug development.

- Environmental Science: Often requires high sensitivity for trace element analysis in environmental samples (water, soil, air).

- Materials Science: Used for characterizing materials, such as metals, polymers, and ceramics, to understand their composition and properties.

- Food and Beverage Industry: Used for quality control, nutritional analysis, and detecting contaminants.

- Petrochemical Industry: Used for analyzing crude oil, petroleum products, and natural gas.

Industry-specific analyzers provide tailored solutions for better outcomes.

Evaluating Instrument Features

Modern elemental analyzers come with various features to enhance usability and performance. Key features need to be considered are:

- User Interface: Intuitive software for easy operation.

- Data Integration: Connectivity for data sharing and reporting.

- Maintenance Needs: Automated cleaning and diagnostic tools.

- Durability: Build quality for demanding environments.

Evaluate features based on your workflow and operational demands.

Future-Proofing Your Investment

Technology evolves rapidly, making future-proofing an important consideration.

- Opt for scalable analyzers with upgrade options.

- Ensure compatibility with emerging software and data platforms.

A future-proof analyzer provides long-term value and adaptability to evolving needs.

Selecting the right elemental analyzer involves a thorough understanding of your analytical requirements, industry-specific needs, and budget constraints. By considering factors such as the elements to be analyzed, sample type, sensitivity, throughput, and vendor support, you can ensure an informed decision. With the right analyzer, you’ll achieve accurate, efficient, and reliable results, maximizing your investment and enhancing your operational capabilities. Feel free to contact us when you need elemental analyzer or any other analytical instruments.