Sterile sample preparation is a fundamental aspect of numerous industries, including pharmaceuticals, biotechnology, and food safety. Any contamination during this process can lead to compromised results, inefficiencies, and even health risks. One key tool for preventing contamination while ensuring consistency is the sterile homogenizer. These devices play a critical role in preparing samples that are free of contaminants while maintaining uniformity.

This article explores the importance of sterile homogenizers, how they ensure consistency and purity, key precautions to follow when using them, and their applications across various industries.

What is a Sterile Homogenizer?

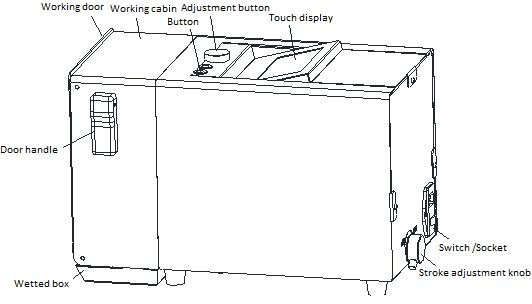

A sterile homogenizer is a specialized laboratory instrument designed to blend, emulsify, or disrupt samples while maintaining a sterile environment. These devices typically use mechanical force to break down materials into uniform particles, ensuring consistency without compromising sterility. Sterile homogenizers often feature sealed systems or utilize disposable components, such as bags, probes, or rotors, to prevent contamination.

The key function of a sterile homogenizer is to process samples in a way that ensures the sample’s environment remains free from external contaminants. These devices are essential for work involving sensitive biological materials, where contamination can skew results or pose health hazards.

How Sterile Homogenizers Ensure Consistency and Purity

Why Consistency Matters in Sample Preparation

Consistency in sample preparation is crucial across all laboratory disciplines. When preparing biological, chemical, or pharmaceutical samples, any variation in the homogenization process can lead to inconsistent results, reduced reproducibility, and inaccurate conclusions. For example, in pharmaceutical testing, uneven homogenization could cause unequal distribution of active ingredients, potentially compromising the safety and efficacy of a drug.

Sterile homogenizers ensure that the process of homogenization is uniform and repeatable. By preventing contamination, they also eliminate a significant variable that can affect experimental outcomes, helping maintain the integrity of results.

How Sterile Homogenizers Ensure Consistency and Purity

Sterile homogenizers use advanced mechanisms to provide consistent, reproducible results while preventing contamination. Here are the key ways these devices achieve their goals:

a. Sealed Systems and Disposable Components

Sterile homogenizers often use sealed systems or disposable parts to ensure no outside contaminants come into contact with the sample. Disposable components such as homogenizing bags, sterile probes, or disposable rotors prevent cross-contamination between samples. This is particularly important in microbiology or pharmaceuticals, where even trace contaminants can drastically alter results.

b. Controlled Processing Environment

These devices are designed to function in highly controlled environments, ensuring that factors like speed, temperature, and pressure are consistent throughout the homogenization process. Consistent mechanical forces lead to uniform particle sizes, which are critical for accurate downstream processing such as filtration or centrifugation.

c. Sterility Validation

Modern sterile homogenizers are subject to rigorous sterility validation processes, ensuring that the equipment is free from microbial contaminants before use. This is particularly important for industries like biotechnology and pharmaceuticals, where contamination can lead to significant regulatory and safety issues.

Precautions for Operating a Sterile Homogenizer

To achieve consistent and contamination-free results when using a sterile homogenizer, follow these specific operational precautions:

- Initial Setup and Sterility Check: Begin by setting up the homogenizer in a clean, designated workspace. Wipe down all surfaces with an appropriate disinfectant, ensuring that both the work area and the homogenizer are as free from contaminants as possible. Place any sample containers, probes, and blades into the sterilizer before starting, and allow them to cool in a sterile environment.

- Assembly in Sterile Conditions: After sterilizing, assemble the homogenizer components within a laminar flow hood or other sterile environment. Avoid touching sterilized parts with bare hands; instead, use sterilized tools or gloved hands, changing gloves if necessary to prevent recontamination.

- Sample Loading and Avoiding Air Contamination: Load samples into the homogenizer chamber carefully to prevent spillage or aerosol generation. Use a sealed sample container if available, or close the homogenizer lid tightly to prevent contamination from the air. Ensure sample containers are closed securely during operation to maintain sterility.

- Set Homogenization Parameters Precisely: Carefully select the appropriate speed and duration for the specific sample type. Lower speeds are generally suitable for fragile cell suspensions, while higher speeds are recommended for denser tissue samples. Adjust these parameters accurately, as incorrect settings can compromise both the sterility and the quality of the homogenized sample.

- Minimizing Sample Exposure and Cross-Contamination: Between runs, always use sterilized probes and containers. If working with multiple samples, consider using single-use, sterile homogenizer probes or containers to prevent any cross-contamination. If reusable, clean and autoclave probes immediately after each use.

- Monitor for Aerosol and Leakage Control: Homogenizing can produce aerosols, especially at high speeds. Always ensure the equipment is securely closed, and if possible, use an aerosol containment hood to protect samples and maintain laboratory safety. Check for leaks during operation and pause immediately if any are detected.

- Post-Processing Clean-Up and Disassembly: After homogenization, carefully remove samples in a sterile environment and promptly transfer them to clean, sealed containers. Disassemble the homogenizer, taking care to keep components sterile if they need to be reused immediately. Clean and sterilize all parts following the manufacturer’s instructions to prepare for the next use.

- Storage and Maintenance for Consistent Sterility: After each session, store all homogenizer parts in a sterilized, sealed container to protect them from dust and contaminants. Regularly maintain and inspect the equipment, replacing worn parts to ensure continued sterility and efficient operation.

By following these detailed operational steps, you can ensure that the sterile homogenizer functions effectively and maintains contamination-free processing across multiple uses.

Applications of Sterile Homogenizers

Sterile homogenizers are indispensable tools in various industries where maintaining sample integrity is critical. Here are some of the key applications:

Pharmaceutical Industry

Sterile homogenizers are widely used in the pharmaceutical industry to prepare samples for drug formulation and testing. During vaccine development, for example, maintaining sterility during sample preparation is essential for producing safe and effective vaccines. These devices ensure that biological samples are blended uniformly without contamination, helping scientists achieve reproducible results.

Microbiology and Biotechnology

In microbiological and biotechnological research, sterile homogenizers are essential for preparing cultures and processing biological samples. Whether used for breaking down cell walls or preparing samples for DNA and RNA extraction, these devices allow researchers to work with pure, uncontaminated samples, critical for accurate data in genetic research.

Food and Beverage Industry

Sterile homogenizers play a vital role in food safety testing, ensuring that samples are prepared in a sterile environment to detect pathogens such as Salmonella or E. coli. In this context, consistent homogenization is important for ensuring that testing is reliable, helping identify potential contaminants before products reach consumers.

Environmental Testing

Environmental labs rely on sterile homogenizers to process soil, water, or air samples for contamination testing. By ensuring the consistency of particle size and purity during preparation, sterile homogenizers help guarantee that environmental samples are free of external contaminants, leading to accurate analyses.

Sterile homogenizers are crucial for ensuring both consistency and purity in sample preparation across various industries. By using sealed systems, disposable components, and maintaining controlled environments, these devices prevent contamination and guarantee uniform homogenization. Their applications span pharmaceutical development, microbiological research, food safety, and environmental testing, making them essential tools for laboratories worldwide. Following proper precautions and maintenance practices can further enhance the performance of these devices, ensuring they continue to deliver contamination-free, consistent results.