Fat extraction is a crucial step in many analytical procedures, particularly in the food, pharmaceutical, and environmental industries. It involves separating fats and oils from a sample matrix. One of the most widely used techniques for this purpose is soxhlet extraction. Here we explores how the soxhlet extractor work in crude fat extraction.

What is Crude Fat?

Crude fat refers to the total lipid content of a sample. It includes a variety of lipids such as triglycerides, phospholipids, and sterols. Accurate determination of crude fat content is essential for various reasons, including:

- Food quality and labeling: Ensuring accurate nutritional information and compliance with food regulations.

- Feed formulation: Optimizing animal feed formulations to meet specific nutritional requirements.

- Pharmaceutical analysis: Assessing the lipid content of drugs and drug products.

- Environmental monitoring: Monitoring lipid pollution in water bodies and soil.

Why Use Soxhlet Extraction for Fat?

Soxhlet extraction is a preferred method for fat extraction due to its several advantages:

- High Efficiency: It enables repeated solvent extraction cycles, reducing solvent consumption. At the same time, the repeated cycles of solvent extraction ensure efficient removal of lipids.

- Automated process: The extraction process can be automated, minimizing labor and time.

- Precision: The closed system minimizes sample loss and contamination.

- Versatility: Suitable for a wide range of sample types, including seeds, meat, dairy, and soil.

In summary, the soxhlet method offers a robust and reproducible approach for crude fat analysis, making it indispensable in laboratories.

How the Soxhlet Extraction Process Works

By leveraging a continuous solvent recycling mechanism, the soxhlet apparatus ensures thorough and consistent fat extraction. This part outlines the preparation, practical steps, and result recording involved in the process, providing a clear guide for you.

Preparation:

- Equipment needed:

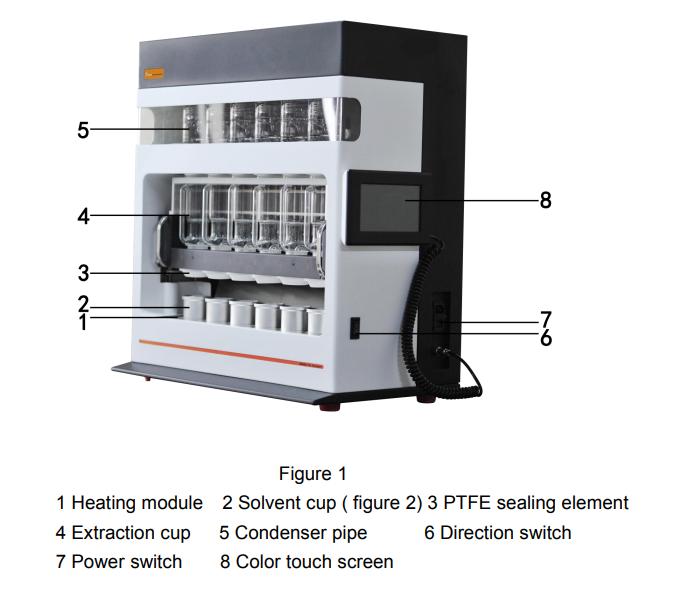

- Soxhlet extractor: A specialized glassware apparatus consisting of a thimble, flask, condenser, and siphon tube.

- Analytical balance: For precise weighing of samples.

- Drying oven: For drying samples and glassware.

- Rotary evaporator: For solvent recovery.

- Water bath: To provide a stable heat source.

- Samples:

Solid samples should be dried and ground to a fine powder.

Liquid samples may require dilution or concentration.

- Reagents/Solvents:

Commonly used solvents include petroleum ether, hexane, or diethyl ether, depending on the sample and fat type.

Practice Steps

- Setup:

- Start by preparing the soxhlet apparatus. Securely connect the round-bottom flask, extraction chamber, and condenser using clamps and ensure all joints are tight to prevent solvent leakage.

- Place the prepared sample into a cellulose thimble and insert it into the extraction chamber. Ensure the thimble fits well to prevent the sample from spilling.

- Fill the round-bottom flask with a sufficient volume of the chosen solvent, typically enough to fill the siphon several times during the extraction.

- Position the soxhlet apparatus on a heating mantle or water bath to provide a stable heat source.

- Extraction:

- Gradually heat the solvent in the round-bottom flask. As it reaches its boiling point, the solvent vaporizes and moves upward into the condenser.

- The condenser cools the solvent vapor, converting it back into liquid form, which drips into the extraction chamber containing the sample.

- As the solvent interacts with the sample, it dissolves the fat and other soluble components. When the solvent in the extraction chamber reaches the siphon’s level, it automatically flows back into the round-bottom flask, carrying the dissolved fat.

- This cycle of evaporation, condensation, extraction, and siphoning continues for 4-6 hours or until complete extraction is achieved. The duration may vary depending on the sample and solvent used.

- Recovery:

- After the extraction, turn off the heat and allow the apparatus to cool to room temperature. Carefully dismantle the soxhlet setup to avoid spills or burns.

- Recover the solvent from the round-bottom flask using a rotary evaporator or similar distillation system. This step helps reduce waste and allows for solvent reuse.

- Dry the flask containing the extracted fat residue in a desiccator or oven at a controlled temperature to remove residual solvent. Continue drying until a constant weight is achieved.

Record Results

Weigh the flask with the extracted fat to determine the crude fat content.

Calculate the fat percentage using the formula:

Crude Fat (%) = [(Weight of Extracted Fat) / (Weight of Sample)] × 100

By adhering to these steps, the soxhlet process ensures accurate and reproducible results.

Applications of Soxhlet in Crude Fat Extraction

The soxhlet extractor is extensively used across various domains:

| Field | Applications |

| Food Industry | Determining fat content in dairy, meat, and processed foods. |

| Ensuring compliance with nutritional labeling standards. | |

| Animal Feed Analysis | Evaluating the energy content and quality of feed. |

| Assessing the suitability of feed formulations for livestock. | |

| Agricultural Research | Measuring lipid content in seeds, nuts, and plant materials. |

| Supporting breeding programs to enhance oil yield. | |

| Environmental Studies | Extracting lipids from soil or sediment samples for pollution analysis. |

| Investigating the bioavailability of hydrophobic contaminants. |

Soxhlet extraction is a reliable and efficient technique for crude fat extraction. By understanding the principles of the process and following proper procedures, accurate and precise results can be obtained. If you have any questions about soxhlet extractor, please feel free to contact us.