Mineral exploration plays a pivotal role in industries such as mining, construction, and energy production. The search for valuable minerals, however, has traditionally been a time-consuming and labor-intensive process. Enter mineral analyzers—a revolutionary technology that has transformed the way we identify and evaluate mineral deposits. By offering unparalleled accuracy, speed, and efficiency, these tools are reshaping the landscape of mineral exploration and unlocking new opportunities for both researchers and industry professionals. This article delves into how mineral analyzers are driving this transformation, exploring their evolution, types, and impact.

The Challenges of Traditional Mineral Exploration

For centuries, mineral exploration relied on manual methods and rudimentary tools. Prospectors would often engage in laborious fieldwork, collecting rock samples for subsequent laboratory analysis. While effective to some degree, this approach posed significant challenges:

- Time-Consuming Processes: Collecting, transporting, and analyzing samples often took weeks or even months.

- High Costs: Laboratory tests and extensive fieldwork required substantial financial investment.

- Inaccuracy: Limited tools often led to imprecise results, resulting in missed opportunities or misjudged mineral deposits.

- Environmental Impact: Traditional exploration methods often disrupted ecosystems, causing long-term damage.

How Modern Mineral Analyzers Overcoming These Challenges?

Mineral analyzers have emerged as a game-changer by addressing these limitations head-on. These devices leverage advanced technologies, such as X-ray fluorescence (XRF), near-infrared (NIR) spectroscopy, and laser-induced breakdown spectroscopy (LIBS), to provide rapid, accurate, and non-destructive analysis of mineral samples. Key aspects including:

Improving Efficiency:

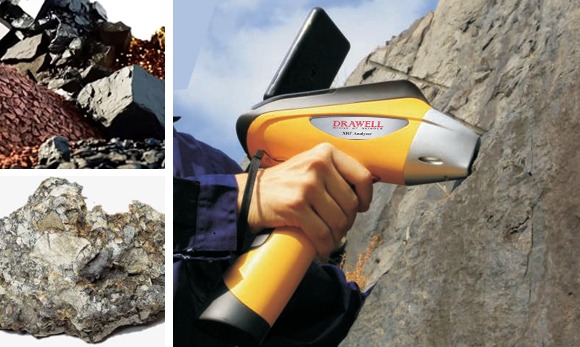

- Faster Analysis: Portable analyzers provide rapid on-site results, significantly accelerating the exploration process. Geologists can quickly assess the mineral composition of rock samples, allowing for immediate decision-making and adjustments to exploration strategies.

- Reduced Sampling: By providing more accurate and timely data, analyzers can minimize the number of samples required, reducing the need for extensive drilling and sampling programs. This translates to significant cost savings and a reduced environmental footprint.

- Real-time Decision Making: Real-time analysis empowers geologists to make informed decisions on-site, such as adjusting drilling plans based on immediate results. This iterative approach optimizes exploration efforts and increases the probability of success.

Reducing Costs:

- Reduced Drilling Costs: By identifying target zones more accurately, analyzers can minimize the number of boreholes required, leading to substantial cost savings in drilling operations.

- Lower Laboratory Costs: On-site analysis significantly reduces the reliance on expensive and time-consuming laboratory tests, further contributing to cost reduction.

- Increased Success Rates: By improving the accuracy and efficiency of exploration, analyzers increase the likelihood of successfully identifying and delineating economically viable mineral deposits.

Enhancing Sustainability:

- Minimized Environmental Impact: By reducing the need for extensive drilling and sampling, analyzers help minimize the environmental disturbance associated with traditional exploration methods.

- Improved Resource Utilization: Analyzers can help identify and extract lower-grade ores more efficiently, maximizing resource recovery and minimizing waste.

These advancements have redefined mineral exploration, making it faster, more sustainable, and more precise than ever before.

Types of Mineral Analyzers

Mineral analyzers can be broadly classified based on the analytical technique they employ:

- X-ray Fluorescence (XRF) Spectrometers:

- Portable XRF (pXRF): Handheld devices widely used for rapid on-site analysis of major and trace elements in rocks, soils, and ores.

- Benchtop XRF: Larger, more powerful systems typically used in laboratories for higher accuracy and precision.

- Raman Spectrometers:

- Handheld Raman: Portable devices used for identifying minerals based on their unique vibrational properties.

- Laser-Induced Breakdown Spectroscopy (LIBS):

- Portable LIBS: Handheld or small, portable systems used for rapid elemental analysis.

- Other Techniques:

- Infrared Spectroscopy (IR): Analyzes the interaction of infrared radiation with the sample.

- Geochemical Sensors: Measure specific geochemical parameters in the environment.

Here are a comparative explanation about these types of mineral analyzers:

| Type | Key Features | Specific Applications | Minerals Analyzed |

| X-Ray Fluorescence (XRF) Spectrometers | Accurate elemental composition analysis. | On-site ore grading and mineral identification. | Metals (e.g., gold, silver, copper, iron), oxides (e.g., titanium dioxide), sulfides (e.g., pyrite, galena), and more. |

| Non-destructive method. | Soil and sediment analysis. | ||

| Portable and lab-based models available. | Quality control in mining and metallurgy. | ||

| Raman Spectrometers | High specificity for crystal structures. | Identifying gemstones and crystalline minerals. | Gemstones (e.g., diamond, sapphire), carbonates (e.g., calcite, aragonite), and silicates (e.g., quartz, feldspar). |

| Non-destructive and portable. | Research in mineralogical studies. | ||

| Effective for complex mineral mixtures. | Detecting inclusions in rocks. | ||

| Laser-Induced Breakdown Spectroscopy (LIBS) | Capable of detecting trace elements. | Exploration of lithium and other light elements. | Light elements (e.g., lithium, beryllium), rare earth elements, alkali metals (e.g., sodium, potassium), and trace metals. |

| Compact and field-friendly. | Rapid field surveys for trace elements. | ||

| Real-time analysis with minimal preparation. | Ore quality assessment. | ||

| Infrared Spectroscopy (IR) | Detects molecular bonds and vibrations. | Identifying clays, carbonates, and organics. | Clays (e.g., kaolinite, montmorillonite), carbonates (e.g., calcite, dolomite), organic compounds, and hydrated minerals. |

| Effective for non-metallic minerals. | Geological surveys and environmental studies. | ||

| Non-invasive method. | Moisture content analysis. | ||

| Geochemical Sensors | Continuous, real-time monitoring. | Monitoring geochemical changes during drilling. | Minerals containing key geochemical indicators (e.g., arsenic, cadmium, lead) and compounds affecting soil/water quality. |

| Integration with drilling equipment. | Environmental impact studies. | ||

| High durability in harsh environments. | Detecting pollutants in soil and water. |

This table summarizes the strengths and uses of these mineral analyzers, making it easy to select the right type for specific tasks.

Mineral analyzers are transforming the landscape of mineral exploration, offering unprecedented speed, accuracy, and efficiency. By overcoming the limitations of traditional methods, these technologies are enabling more targeted exploration programs, reducing costs, and minimizing environmental impact. As technology continues to advance, we can expect even more sophisticated and integrated solutions, further revolutionizing the way we discover and extract the Earth’s valuable mineral resources.