The field of melting point determination has experienced remarkable advancements, particularly in instruments designed to analyze multiple samples simultaneously. These innovations are transforming the landscape of laboratory testing, offering laboratories the ability to process larger volumes of samples in a more efficient, accurate, and cost-effective manner. With growing demand for higher throughput, precision, and automation, multi-sample melting point meters are more and more widely in various industries such as pharmaceuticals, chemicals, food science, and materials research.

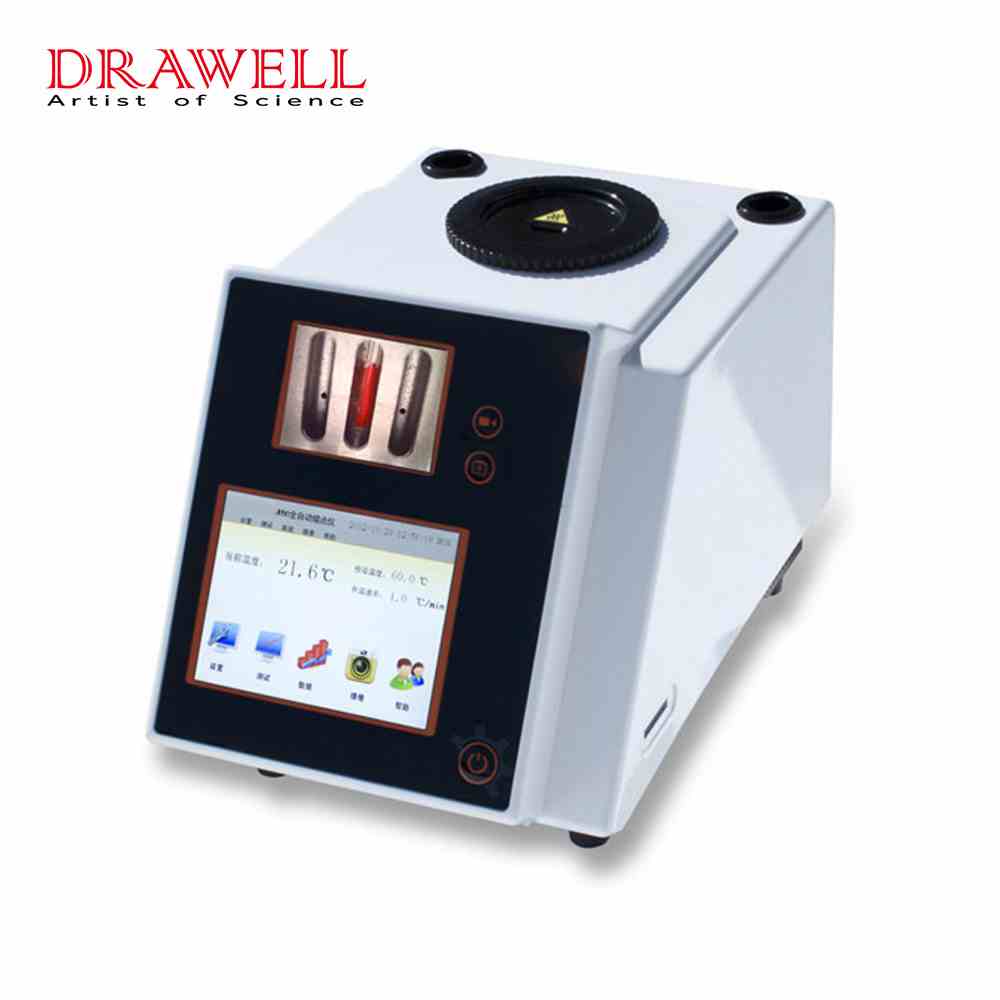

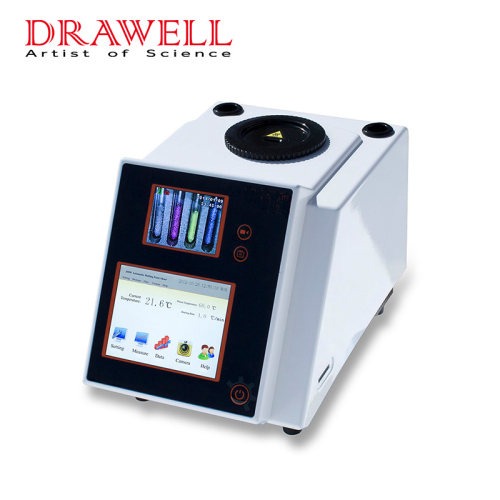

What are Melting Point Meters

Melting point meters are analytical instruments used to determine the temperature at which a substance transitions from a solid to a liquid. This temperature, known as the melting point, is an essential property for characterizing materials in various industries, such as pharmaceuticals, chemicals, and materials science. Melting point meters work by gradually heating a sample and monitoring the temperature at which it begins to melt, providing precise measurements that can help identify purity, composition, and quality of a substance. Advanced models can automate the testing process, improving accuracy, efficiency, and throughput in laboratories.

Why Need Melting Point Meters for Analyzing Multiple Samples Simultaneously

- Increased Throughput and Efficiency

In traditional methods, each sample is tested one at a time, which can be highly time-consuming. Laboratories, especially those working with high volumes of samples such as in pharmaceutical or chemical industries, need to perform multiple analyses in a short amount of time. Multi-sample melting point meters allow for the simultaneous analysis of several samples, significantly reducing the total testing time. By processing multiple samples at once, laboratories can achieve higher throughput, optimizing their operations and speeding up the entire testing process.

- Accurate Results for Multiple Samples

When analyzing multiple samples simultaneously, melting point meters are vital that each sample is accurately measured to ensure the reliability of results. This level of accuracy is essential when working with substances that have narrow or overlapping melting point ranges, as even the slightest variation can significantly impact the outcome.

- Enhanced Productivity and Resource Utilization

Laboratories often operate under tight deadlines, and with the growing demand for testing, productivity has become a critical factor. The ability to test multiple samples in one go maximizes the use of equipment, space, and technician time. With fewer machines required and less manual labor involved, laboratories can manage resources more efficiently, improving productivity and reducing operational costs. This is especially valuable in research settings where the time to complete experiments is critical and where cost efficiency can directly impact the overall budget.

- Cost Savings

Traditional melting point meters, which analyze one sample at a time, require more time, labor, and often more equipment to meet testing demands. In contrast, multi-sample meters that can handle several samples simultaneously reduce the number of tests that need to be run, minimizing labor and time costs. These meters often come with integrated software that streamlines data collection, reducing the need for additional personnel for data entry or result processing. As a result, laboratories benefit from lower operating costs while still meeting high testing demands.

- Improved Quality Control and Consistency

Multi-sample meters help improve the consistency of results, especially when analyzing substances with similar characteristics or testing multiple batches of the same compound. By analyzing all samples simultaneously under identical conditions, the potential for inconsistencies caused by minor procedural or environmental differences is minimized. This is particularly important in quality control processes, where precision is key to maintaining product standards and ensuring that each batch meets the required specifications.

- Scalability for Large-Scale Operations

As laboratories scale up operations, the need for equipment that can handle increased workloads becomes essential. Multi-sample melting point meters offer scalability, allowing laboratories to expand their testing capabilities without needing to invest in a large number of individual instruments. This scalability is particularly beneficial in industries such as pharmaceuticals, where large batches of materials need to be tested quickly and efficiently, ensuring that production timelines are met without compromising quality.

Advancements in Melting Point Meters for Analyzing Multiple Samples Simultaneously

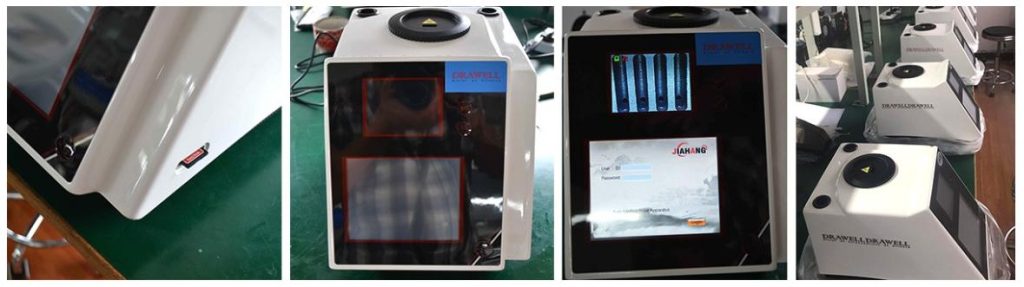

1. Integration of Advanced Automation Systems

In earlier versions of melting point meters, the process was largely manual. Technicians were required to load each sample, monitor the heating process, and record results individually. Advanced automatic melting point meters allows for the simultaneous analysis of multiple samples with minimal human intervention. Automation reduces the potential for human error and accelerates the testing process, thus improving overall laboratory efficiency. This also frees up technicians to focus on other tasks, leading to optimized workflow and greater productivity in busy research or quality control environments.

2. Improved Precision of Temperature Control and Monitoring Systems

Advanced sensors and temperature management technology have allowed for more accurate and reliable measurements, even when analyzing samples with narrow or overlapping melting point ranges. Multi-sample melting point meters are now equipped with high-resolution thermometers that can detect minute temperature fluctuations, ensuring that each sample’s melting point is recorded with unparalleled accuracy. These improvements are particularly vital for industries like pharmaceuticals, where even small variations in melting point can have significant implications for product quality and consistency.

3. Enhanced Capacity for Handling Multiple Samples

The newer models of multi-sample melting point meters are equipped with modular sample holders, allowing for a greater number of samples to be analyzed simultaneously. These meters can manage up to ten or more samples at a time, depending on the model, greatly increasing throughput. This increased capacity not only reduces the time required to test a large batch of samples but also minimizes the need for additional equipment, consolidating multiple analyses into one efficient process. The versatility of these devices has made them invaluable in laboratories that need to analyze a high volume of substances quickly and accurately.

4. Improved Sample Handling Capabilities

Melting point instruments now accommodate a wide range of sample types, including pure compounds, mixtures, and complex formulations. The ability to adjust sample containers and sizes according to specific requirements allows for better customization. This flexibility is essential for industries that work with diverse materials, as the same instrument can be used for different types of analyses. Some meters even allow for the use of different types of sample holders, such as capillaries, microtubes, or specialized crucibles, ensuring compatibility with a broad spectrum of sample configurations.

5. Integrated Data Management Systems

With the incorporation of advanced software, these meters can now record, analyze, and store data automatically, streamlining the process of result analysis. Real-time monitoring and visualization features enable users to track the progress of each sample’s melting process, providing immediate feedback on their condition. Some models can even generate detailed reports and provide statistical analysis, allowing for a more thorough evaluation of sample properties. Furthermore, these systems often offer seamless integration with laboratory information management systems (LIMS), facilitating enhanced data organization, compliance, and traceability.

6. Faster Analysis Time

In traditional setups, each sample had to be tested individually, leading to longer analysis periods, especially when working with large numbers of samples. Multi-sample meters allow laboratories to analyze several samples in parallel or sequentially with rapid temperature changes, thus significantly reducing the total testing time. This rapid analysis is especially valuable in environments where time is of the essence, such as in high-throughput pharmaceutical testing or research settings.

7. Precisely Control Temperature Ramp Rates

By allowing users to control the heating speed with great accuracy, modern meters are able to analyze substances with complex phase transitions or overlapping melting points more effectively. This is essential for differentiating between similar substances or evaluating materials with very close melting ranges. The ability to adjust ramp rates also adds another layer of customization to the analysis, enabling operators to fine-tune their experiments for more detailed and comprehensive results.

8. User-friendly Interfaces and Compact Designs

Multi-sample melting point meters have become more accessible and practical. Advanced models often come with intuitive touchscreens, streamlined controls, and simple navigation, making them easier to operate for both novice and experienced technicians. Additionally, the compact design of many of these instruments ensures they can fit comfortably into a variety of laboratory environments without taking up excessive space.

In summary, the advancements in multi-sample melting point meters have revolutionized laboratory analysis, providing significant improvements in automation, accuracy, speed, and data management. These instruments offer increased throughput, enhanced accuracy, and greater versatility, making them a valuable tool in any laboratory that deals with large sample sets.