Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) has emerged as a vital tool for high-throughput analysis in industrial laboratories. Its ability to simultaneously detect and quantify multiple elements with high precision and speed makes it critical in modern analytical workflows. This article explores how ICP-OES addresses the demands of industrial laboratories for efficiency, accuracy, and scalability.

The Role of ICP-OES in Industrial Laboratories

Industrial laboratories are often tasked with processing large volumes of samples while maintaining stringent accuracy and compliance standards. ICP-OES meets these requirements by offering:

- Simultaneous Multi-Element Analysis: ICP-OES can measure multiple elements simultaneously in a single sample, making it ideal for industries like metallurgy, environmental monitoring, and pharmaceuticals.

- High Sensitivity and Accuracy: The technique’s capacity to detect trace and ultra-trace levels of elements ensures compliance with quality and safety standards, particularly in highly regulated industries.

- Rapid Throughput: With its ability to analyze hundreds of samples per day, ICP-OES helps laboratories meet tight deadlines without compromising reliability.

Key Features of ICP-OES Driving High-throughput Analysis in Industrial Laboratories

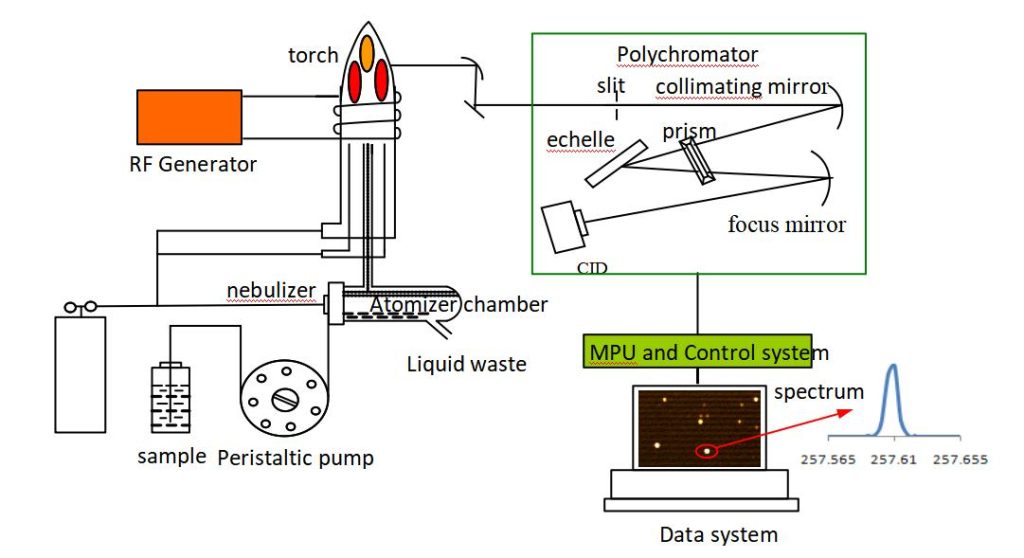

- Simultaneous Multi-Element Detection: ICP-OES systems are designed to detect multiple elements simultaneously, significantly reducing analysis time. By measuring several wavelengths in a single run, laboratories can increase sample throughput without sacrificing accuracy.

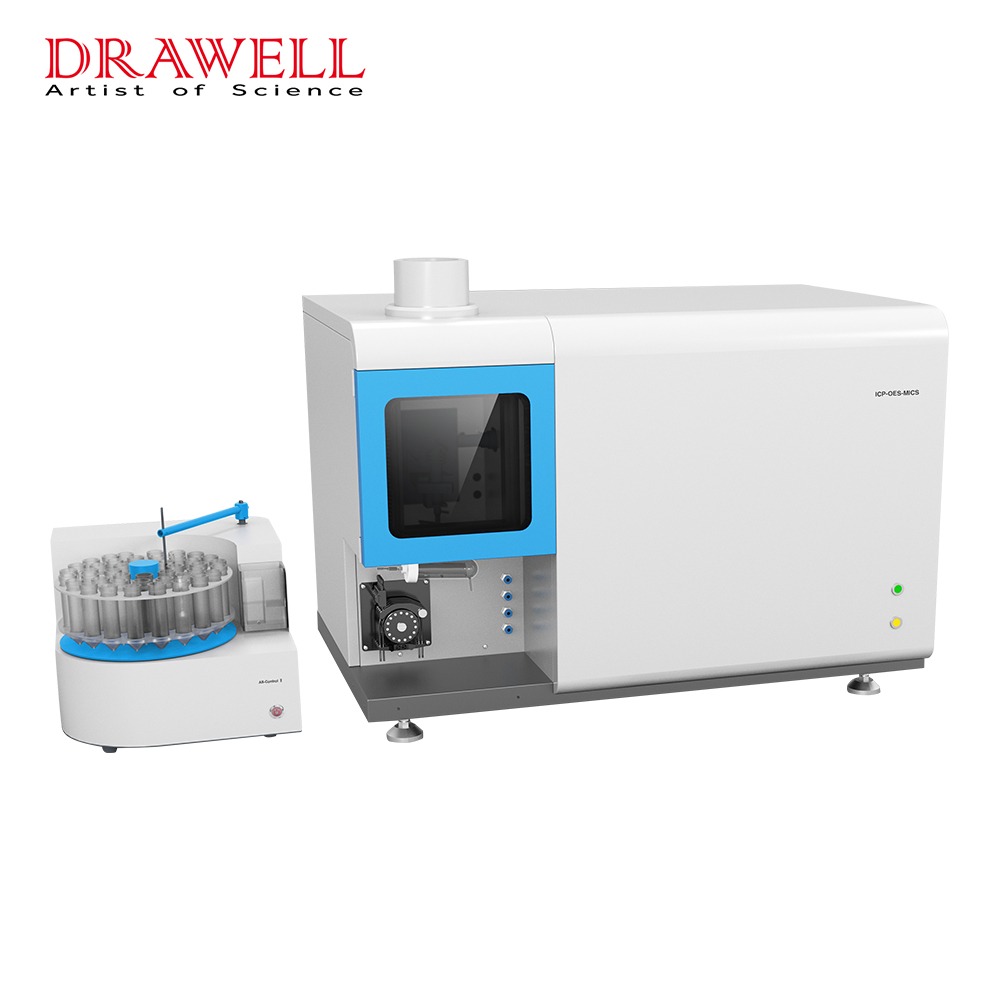

- Automated Sample Handling: Modern ICP-OES instruments incorporate advanced autosamplers and automated sample introduction systems. These features allow seamless, unattended operation for extended periods, minimizing operator intervention and enhancing workflow efficiency.

- High Sensitivity and Wide Dynamic Range: ICP-OES offers excellent detection limits, often in the parts-per-billion (ppb) range, while also accommodating high-concentration samples. This dual capability ensures that a wide range of industrial applications—from trace metal analysis to bulk composition determination—can be handled without additional sample preparation.

- Robust Plasma Technology: The robustness of ICP-OES plasma sources allows the analysis of diverse sample matrices, including those with high dissolved solids or complex organic components. This capability reduces the frequency of instrument cleaning and maintenance, ensuring uninterrupted operation in demanding environments.

- Advanced Optical Systems: State-of-the-art optical designs enhance resolution and sensitivity, enabling accurate differentiation between closely spaced spectral lines. These innovations improve data reliability, especially when analyzing samples with overlapping elemental spectra.

- Software and Data Management Integration: ICP-OES spectrometers feature intuitive software with functionalities, which includes real-time monitoring of analysis progress, automatic calibration and optimization, integration with Laboratory Information Management Systems (LIMS) ,etc. These capabilities streamline data management and reporting, supporting laboratories with high sample loads.

- Matrix Tolerance: ICP-OES systems are engineered to handle complex matrices such as brines, alloys, or industrial waste with minimal interferences. Advanced technologies, like internal standardization and background correction, further enhance accuracy in challenging samples.

- Minimal Downtime with Durable Components: Durable torch designs, self-cleaning nebulizers, and efficient cooling systems reduce wear and maintenance. This reliability ensures maximum instrument uptime, which is critical for high-throughput operations.

- Energy Efficiency and Cost-Effectiveness: Modern ICP-OES systems consume less argon gas and have optimized power consumption. These improvements reduce operational costs, making high-throughput analysis more economically viable for industrial labs.

- Scalability and Customization: Many ICP-OES systems offer scalable configurations, allowing laboratories to adapt the instrument to their specific throughput and analytical needs. Optional accessories, such as microwave digestions or dilution systems, further enhance flexibility.

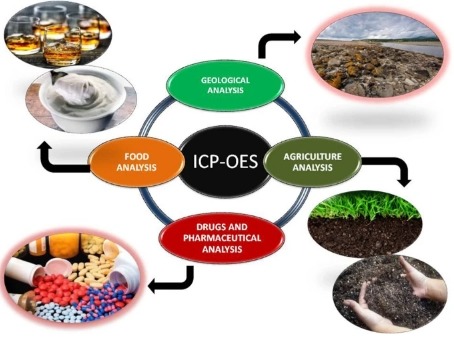

Applications of ICP-OES in Industrial Laboratories

This chart highlights the versatility and importance of ICP-OES in addressing the analytical needs of various industrial sectors.

| Industry | Application | Purpose |

| Metallurgy | Composition analysis of alloys and metals | Ensures material properties meet design and performance specifications. |

| Environmental Monitoring | Analysis of water, soil, and air for heavy metals and pollutants | Aids in pollution control, regulatory compliance, and environmental remediation. |

| Pharmaceuticals | Detection of elemental impurities in drug formulations | Ensures compliance with regulatory guidelines like ICH Q3D and guarantees patient safety. |

| Petrochemicals | Detection of trace metals in fuels, lubricants, and crude oil | Maintains product quality, prevents equipment corrosion, and adheres to environmental regulations. |

| Mining and Geology | Elemental analysis of ores, minerals, and geological samples | Supports resource estimation, quality control, and process optimization in mining operations. |

| Food and Beverage | Analysis of trace elements in food products, beverages, and agricultural inputs | Ensures product safety, quality, and compliance with food safety regulations. |

| Electronics | Purity testing of raw materials and quality control in semiconductor manufacturing | Guarantees high-purity materials for optimal device performance. |

| Energy and Power | Analysis of feedstocks, catalysts, and by-products in power generation and renewable energy sectors | Optimizes efficiency, ensures compliance with safety standards, and monitors environmental impact. |

| Chemical Manufacturing | Quality control of raw materials, intermediates, and finished products | Ensures consistent product composition and performance in industrial chemical production. |

| Automotive | Elemental analysis of coatings, fluids, and components | Ensures durability, performance, and compliance with automotive industry standards. |

Challenges and Solutions in ICP-OES for High-throughput Analysis in industrial laboratories

- Matrix Interferences

Complex sample matrices, such as those with high dissolved solids, organics, or acids, can lead to spectral interferences and signal suppression or enhancement.

Solutions:

- Use internal standards to correct matrix effects.

- Optimize sample preparation techniques, such as dilution or digestion, to reduce complexity.

- Implement background correction methods to minimize spectral overlap.

- Instrument Downtime

Frequent maintenance due to clogs, torch wear, or contamination disrupts workflow in high-throughput operations.

Solutions:

- Employ self-cleaning nebulizers and durable torch designs to reduce maintenance frequency.

- Schedule regular preventive maintenance to avoid unexpected breakdowns.

- Use high-quality reagents and ultrapure water to minimize contamination.

- Data Overload

Handling and interpreting large volumes of data generated during high-throughput analysis can be overwhelming.

Solutions:

- Leverage integrated software for automated data processing and reporting.

- Implement Laboratory Information Management Systems (LIMS) for efficient data management and traceability.

- Use real-time monitoring tools to identify and address anomalies during analysis.

- High Argon Gas Consumption

ICP-OES systems require a significant amount of argon gas, leading to high operational costs.

Solutions:

- Opt for gas-saving modes available in modern ICP-OES instruments.

- Use plasma optimization techniques to reduce gas flow rates without compromising performance.

- Consider alternative gas supplies or bulk purchasing agreements to lower costs.

- Sensitivity to Contaminants

Contaminants in the laboratory environment or during sample handling can compromise accuracy.

Solutions:

- Work in clean environments to minimize airborne contaminants.

- Use dedicated sample handling tools to prevent cross-contamination.

- Perform regular calibration and use high-purity standards to ensure accuracy.

- Long Analysis Times for Complex Samples

Samples with multiple analytes or high matrix complexity can extend analysis time.

Solutions:

- Use simultaneous multi-element detection capabilities to analyze multiple elements at once.

- Employ optimized methods and pre-defined protocols to streamline operations.

- Upgrade to high-speed ICP-OES systems for faster processing.

- Training and Skill Requirements

Operating and maintaining ICP-OES instruments require skilled personnel, which can be a bottleneck in high-throughput labs.

Solutions:

- Provide comprehensive training programs for laboratory staff.

- Use intuitive software interfaces that simplify operation for users of varying skill levels.

- Partner with instrument manufacturers for technical support and advanced training.

In conclusion, ICP-OES has proven itself as an indispensable tool for high-throughput analysis in industrial laboratories. Through combining speed, accuracy and adaptability, it ensures laboratories can meet the evolving demands of modern industries.

2.jpg)