In the intricate world of food processing, precision and efficiency are paramount. Moisture content plays a pivotal role in determining the quality, safety, and shelf life of various food products. Traditionally, measuring moisture levels involved time-consuming and labor-intensive methods. However, the advent of halogen moisture meters has revolutionized the landscape, offering an innovative and accurate solution to the challenges faced by the food processing industry.

Why Halogen Moisture Meters are Important in Food Processing

The Significance of Moisture Content in Food Processing:

Moisture content is a critical factor in the food processing industry, influencing product quality, taste, texture, and shelf life. High moisture levels can lead to bacterial growth, spoilage, and degradation of product quality, while excessively low moisture content can result in products that are too dry and unpalatable. Achieving the optimal moisture level is essential for ensuring the safety, flavor, and longevity of food products.

Traditional Methods vs. Halogen Moisture Meters:

Historically, food processors relied on time-consuming and less precise methods to measure moisture content, such as oven drying, air drying, or chemical analysis. These methods often required significant time and resources, delaying production processes and compromising efficiency. Enter halogen moisture meters, a game-changer in the industry.

3 Significant Improvements of Halogen Moisture Meters in Food Processing

Halogen moisture meters have revolutionized food processing by providing a fast, accurate, and non-destructive way to measure the moisture content of food products. This has led to significant improvements in food quality, safety, and efficiency.

- Improved food quality

Halogen moisture meters allow food processors to ensure that their products have the correct moisture content. This is important for both quality and safety. For example, too much moisture in bread can make it soggy and prone to mold growth. Too little moisture can make it dry and crumbly. Halogen moisture meters help food processors to avoid these problems by allowing them to precisely control the moisture content of their products.

- Improved food safety

Halogen moisture meters can also be used to ensure that food products are safe to eat. For example, high moisture levels in meat can promote the growth of harmful bacteria. Halogen moisture meters can help to prevent this by allowing food processors to identify meat products that have too much moisture and take corrective action.

- Improved efficiency

Halogen moisture meters have also helped to improve the efficiency of food processing operations. By providing a fast and accurate way to measure moisture content, halogen moisture meters have helped to reduce the amount of time and labor required to test food products. This has led to significant cost savings for food processors.

In addition to the benefits listed above, halogen moisture meters have also revolutionized food processing by:

Reducing product waste

Improving shelf life

Simplifying quality control procedures

Facilitating new product development

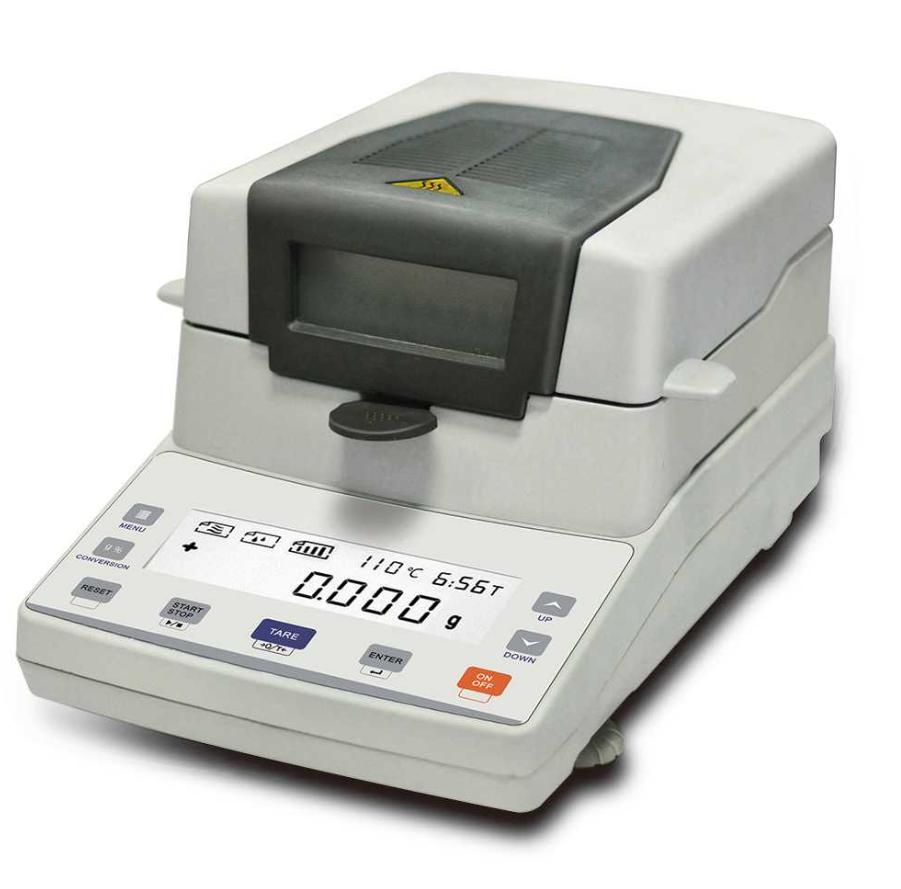

How do Halogen Moisture Meters Work?

Halogen moisture meters work by measuring the amount of electrical resistance between two electrodes. The electrodes are inserted into the food product and a current is passed through them. The resistance between the electrodes is inversely proportional to the moisture content of the food product. The higher the moisture content, the lower the resistance.

Halogen moisture meters are very accurate and can measure moisture content to within +/- 0.1%. They are also very fast, with most models providing readings within seconds.

Applications of Halogen Moisture Meters in Food Processing

Halogen moisture meters are used in a wide variety of food processing applications, including:

- Baking: To measure the moisture content of dough, bread, and other baked goods.

- Meat processing: To measure the moisture content of meat, poultry, and fish.

- Dairy processing: To measure the moisture content of milk, cheese, and other dairy products.

- Cereal processing: To measure the moisture content of grain, flour, and other cereal products.

- Snack food processing: To measure the moisture content of potato chips, pretzels, and other snack foods.

- Fruit and vegetable processing: To measure the moisture content of fresh, frozen, and dried fruits and vegetables.

Conclusion

Halogen moisture meters have revolutionized food processing by providing a fast, accurate, and non-destructive way to measure the moisture content of food products. This has led to significant improvements in food quality, safety, and efficiency. Halogen moisture meters are used in a wide variety of food processing applications, including baking, meat processing, dairy processing, cereal processing, snack food processing, and fruit and vegetable processing.