Melting point measurement is a fundamental technique in many scientific and industrial fields. Traditionally reliant on manual observation, this technique has evolved significantly with the integration of video technology. The advent of advanced video systems has transformed the precision, efficiency, and reliability of melting point determination. This article explores the latest advancements in video technology for melting point measurement and their impact on laboratory practices.

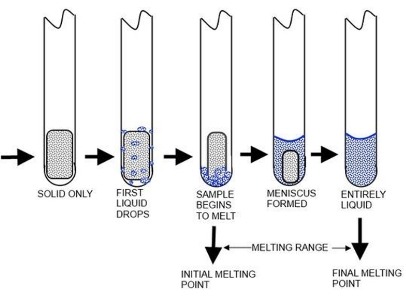

Understanding Melting Point Measurement

This chart provides a simplified overview of the essential elements of melting point measurement.

| Aspect | Description |

| Definition | The temperature at which a solid substance changes to a liquid under atmospheric pressure. |

| Importance | Used to identify and characterize compounds, assess purity, and determine material properties. |

| Factors Affecting Melting Point | Purity, molecular structure, pressure, and intermolecular forces. |

| Methods of Measurement | – Capillary tube method – Thermal analysis (DSC, TGA) – Automated video-based systems |

| Applications | – Pharmaceuticals – Chemicals – Materials science – Food and cosmetics industries |

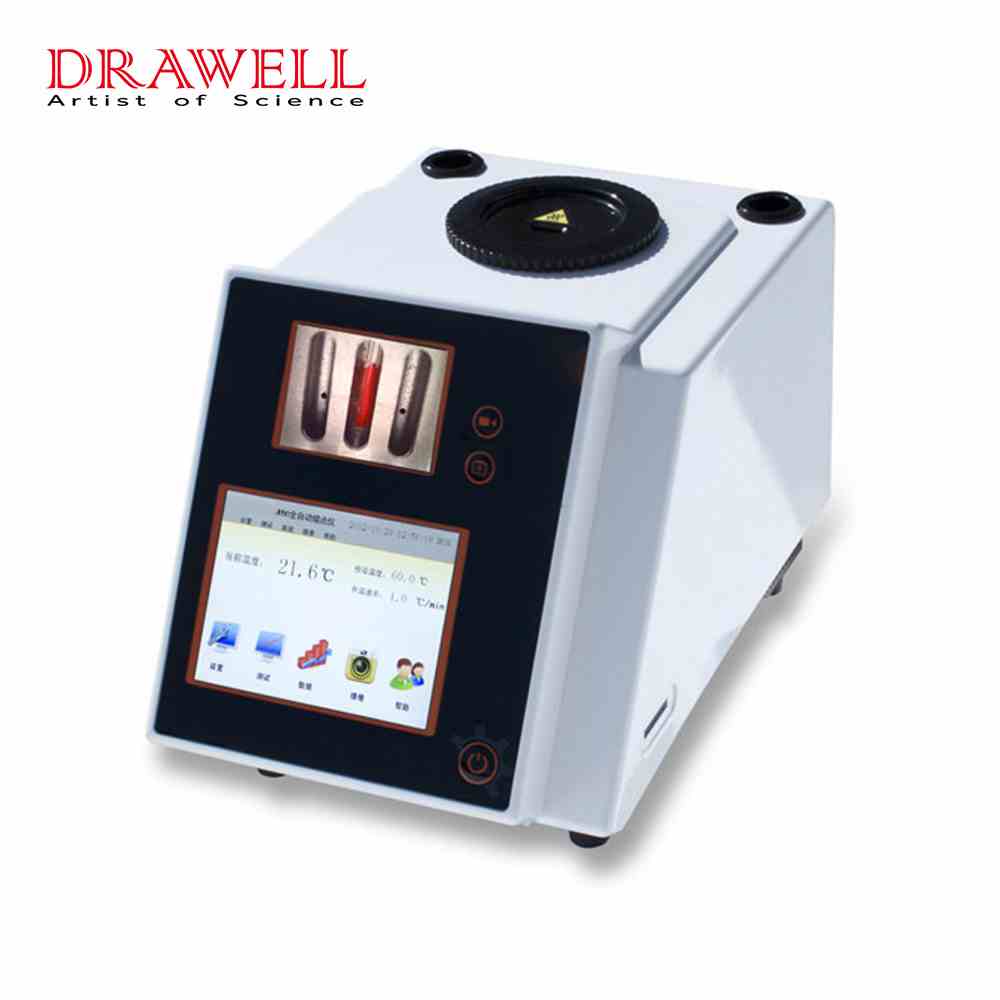

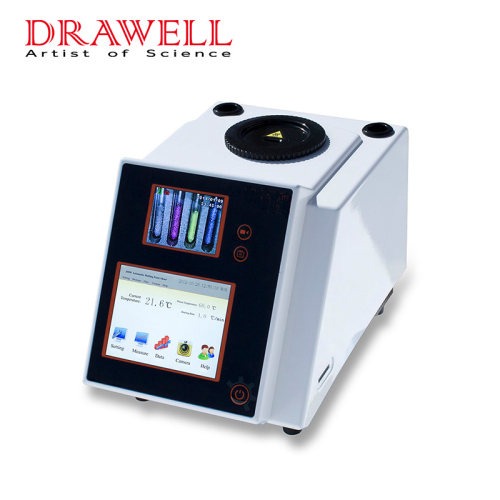

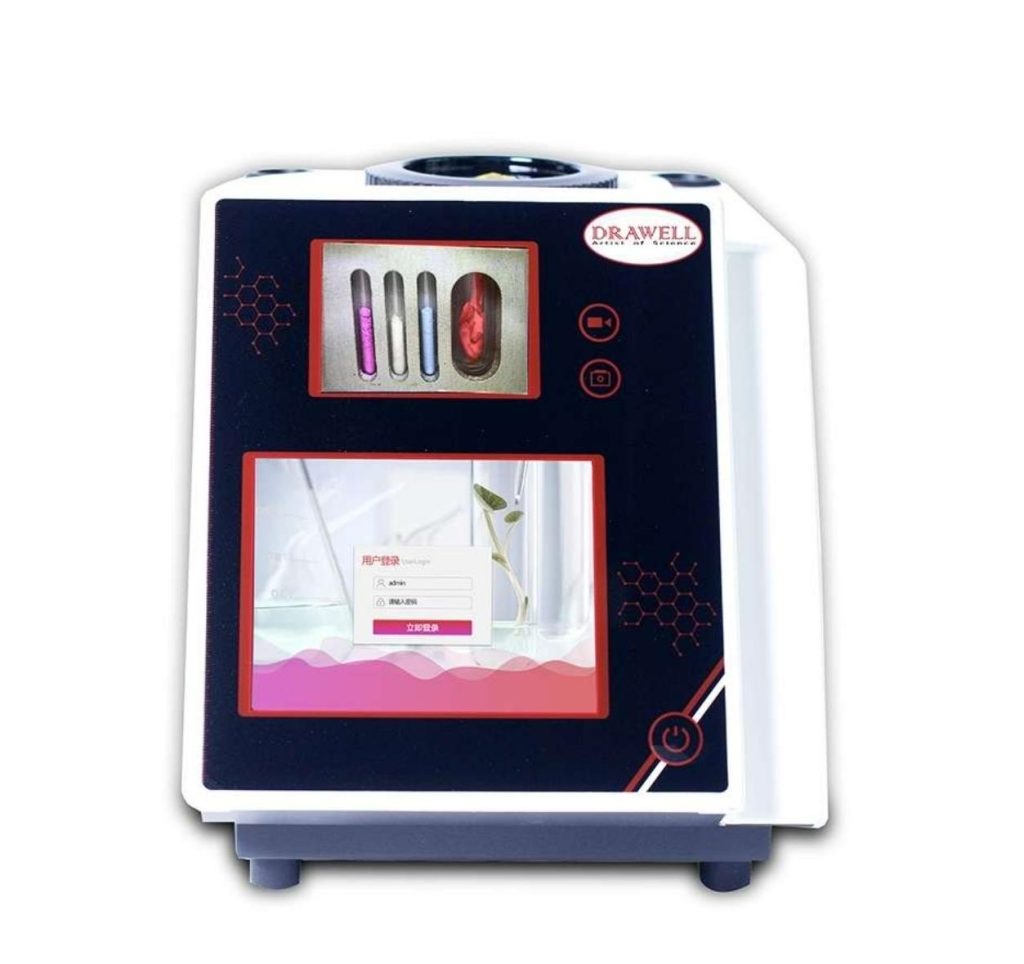

| Typical Instruments | Capillary melting point apparatus, automatic melting point meters, and digital video systems. |

Key Advancements in Video Technology for Melting Point Measurement

1. High-Resolution Video Capture

One of the most notable advancements in video technology for melting point measurement is the enhancement of video resolution. Modern video melting point meters are equipped with high-resolution cameras that capture detailed images of the sample as it undergoes melting. This improved image quality allows for more precise observation of melting behaviors, including the exact moment when a substance transitions from solid to liquid. High-resolution video capture ensures that even subtle changes in the sample’s appearance are detected, leading to more accurate melting point measurements.

2. Real-Time Monitoring and Analysis

Advancements in video technology have enabled real-time monitoring and analysis of the melting process. Continuous video recording provides a dynamic view of the sample as it heats up, allowing for immediate assessment of melting point data. Real-time analysis software can process video feeds to identify key melting events, such as the onset of melting and the completion of the process. This capability is particularly valuable in high-throughput laboratories, where quick and accurate analysis is crucial for handling large volumes of samples.

3. Automated Image Processing and Interpretation

The integration of sophisticated image processing algorithms has significantly enhanced the interpretation of video data in melting point meters. Automated image analysis systems can detect and quantify melting phenomena with minimal human intervention. These systems use algorithms to analyze video frames, identify key melting transitions, and calculate the precise melting point. Automated interpretation reduces the potential for human error and provides consistent results, improving the reliability of the measurements.

4. Enhanced Documentation and Data Management

Modern video technology has improved the documentation and management of melting point data. Video melting point meters now include features for storing and organizing video recordings along with melting point data. This integration allows for comprehensive documentation of each test, including time-stamped video evidence of the melting process. The ability to replay and review video recordings is invaluable for verifying results, troubleshooting discrepancies, and ensuring compliance with quality control standards.

5. Advanced Visualization Tools

Recent advancements in video technology have introduced advanced visualization tools that enhance the analysis of melting point data. These tools include graphical representations of melting profiles, temperature vs. time plots, and overlay comparisons of different samples. Visualization features enable researchers to gain deeper insights into the melting behavior of materials, facilitating more informed decision-making and analysis.

6. Integration with Laboratory Information Management Systems (LIMS)

Seamless integration with Laboratory Information Management Systems (LIMS) is a key advancement in video technology for melting point measurement. Modern melting point meters can automatically transfer video and data records to LIMS, streamlining data management and ensuring accurate record-keeping. This integration allows for efficient tracking, analysis, and reporting of melting point data, enhancing overall laboratory efficiency and compliance with regulatory requirements.

7. User-Friendly Interfaces and Software

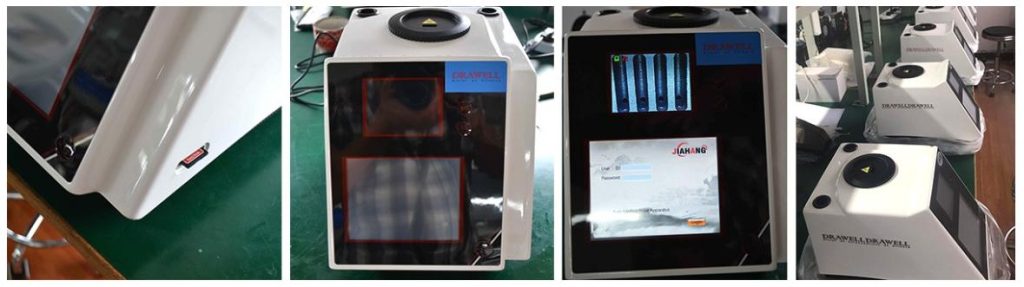

The development of user-friendly interfaces and software has made advanced video technology more accessible and easier to use. Touchscreen controls, intuitive navigation, and pre-configured testing methods enhance the user-friendly features of melting point meters. Software features such as automated setup, customizable test parameters, and real-time feedback improve the user experience and facilitate quicker, more accurate measurements.

Diverse Applications of Video Technology for Melting Point Measurement

This chart provides a clear overview of how video technology is applied across different industries for melting point measurement.

| Industry/Field | Applications |

| Pharmaceutical | 1. Drug Purity Analysis 2. Formulation Development 3. Quality Control |

| Chemical | 1. Compound Identification 2. Purity Assessment 3. Reaction Monitoring |

| Food | 1. Ingredient Analysis 2. Quality Assurance 3. Process Optimization |

| Cosmetics | 1. Product Development 2. Quality Control 3. Stability Testing |

| Materials Science | 1. Material Characterization 2. Research and Development 3. Quality Assurance |

| Academic/Research | 1. Educational Purposes 2. Scientific Research |

| Regulatory Compliance | 1. Documentation 2. Audit and Inspection |

Future Innovations in Video Technology for Melting Point Measurement

The field of melting point measurement has evolved significantly with advancements in video technology, and ongoing innovations promise to further enhance accuracy, efficiency, and data analysis capabilities.

1. Artificial Intelligence (AI) and Machine Learning

- Automated Data Analysis: AI and machine learning algorithms can analyze video data to identify melting points with higher precision and reduced human intervention. These technologies can learn from previous data to improve the accuracy of melting point determinations and handle complex samples.

- Predictive Analytics: AI could enable predictive analytics by analyzing trends and patterns in melting point data, allowing for anticipatory adjustments in testing protocols and better forecasting of material behaviors.

2. Enhanced Imaging Techniques

- Thermal Imaging: Integration of thermal imaging technology can provide detailed temperature distribution maps of the sample during the melting process. This can help in understanding localized melting behaviors and improving accuracy in determining the melting point.

- Multispectral Imaging: Future systems may incorporate multispectral imaging to capture data across various wavelengths, offering more comprehensive analysis of the sample’s thermal properties and melting characteristics.

3. Integration with Advanced Sensors

- Micro-Sensors: Miniaturized sensors could be integrated into melting point meters to provide more localized temperature measurements and enhance the precision of melting point determinations.

- Real-Time Chemical Analysis: Combining video technology with real-time chemical analysis sensors can provide simultaneous melting point data and chemical composition analysis, offering a more complete characterization of the sample.

4. Improved Automation and Robotics

- Robotic Handling: Advanced robotics could automate sample handling, loading, and unloading processes, further increasing the throughput and efficiency of melting point measurement systems.

- Automated Calibration: Future systems may feature automated calibration processes to ensure consistent and accurate measurements, reducing the need for manual adjustments and maintenance.

5. Miniaturization and Portability

- Compact Devices: Development of miniaturized and portable melting point meters could enable on-site testing and analysis in various settings, including field research and remote laboratories.

- Mobile Integration: Integration with mobile devices and apps could allow users to monitor and control melting point measurements remotely, providing greater flexibility and accessibility.

6. Integration with Other Analytical Techniques

- Hybrid Instruments: Future melting point meters may combine video technology with other analytical techniques, such as differential scanning calorimetry (DSC) or spectroscopy, to provide a more comprehensive analysis of material properties.

- Cross-Method Analysis: Integration with other methods could enable simultaneous measurement of melting points and other material characteristics, enhancing the depth of analysis and interpretation.

7. Sustainability and Eco-Friendliness

- Energy-Efficient Designs: Development of energy-efficient systems and components can reduce the environmental impact of melting point measurement devices and contribute to sustainable laboratory practices.

- Eco-Friendly Materials: Use of sustainable and recyclable materials in device construction can further align with environmental conservation goals and reduce waste.

Overall, Advancements in video technology have revolutionized melting point measurement, offering enhanced resolution, real-time monitoring, automated analysis, and improved data management.With the continue technical innovations, the integration of advanced video systems will further enhance the accuracy and reliability of melting point measurements, across a wide range of scientific and industrial applications