Maintaining consistency is crucial for polymer materials used in various industries, from packaging to medical devices. Inaccurate or inconsistent polymers can compromise performance and even pose safety risks. Fortunately, an incredibly versatile tool called the Fourier-transform infrared (FTIR) spectrophotometer provides a powerful means to assess the consistency of polymer materials.

What is an FTIR Spectrophotometer?

Imagine a lightbeam bouncing off different parts of a polymer molecule, each part vibrating at its unique frequency. An FTIR spectrophotometer shines a broad spectrum of infrared light onto the polymer sample. Specific functional groups within the polymer molecule absorb certain wavelengths of this light, creating a unique “fingerprint” in the form of an infrared spectrum. By analyzing this spectrum, we can identify the types and amounts of functional groups present and gain valuable insights into the polymer’s chemical composition and structure.

How FTIR Spectrophotometer is used to Analyze Polymer Materials?

FTIR spectroscopy shines a light on the intricate world of polymers, revealing their chemical composition and structural secrets. Let’s delve into how this powerful technique works, from sample preparation to spectral interpretation, and discover the wealth of information it unlocks about these versatile materials.

Sample Prep Methods for FTIR Analysis

Before the symphony of infrared radiation begins, the polymer sample needs to be prepped for its starring role. Here are some common methods:

- Thin Films: For polymers that dissolve easily, like PVA or PS, preparing a thin film by casting a solution onto a suitable substrate, like NaCl or KBr, is ideal.

- Powder Pellets: Grinding the polymer into a fine powder and mixing it with KBr powder creates a pellet that can be directly analyzed.

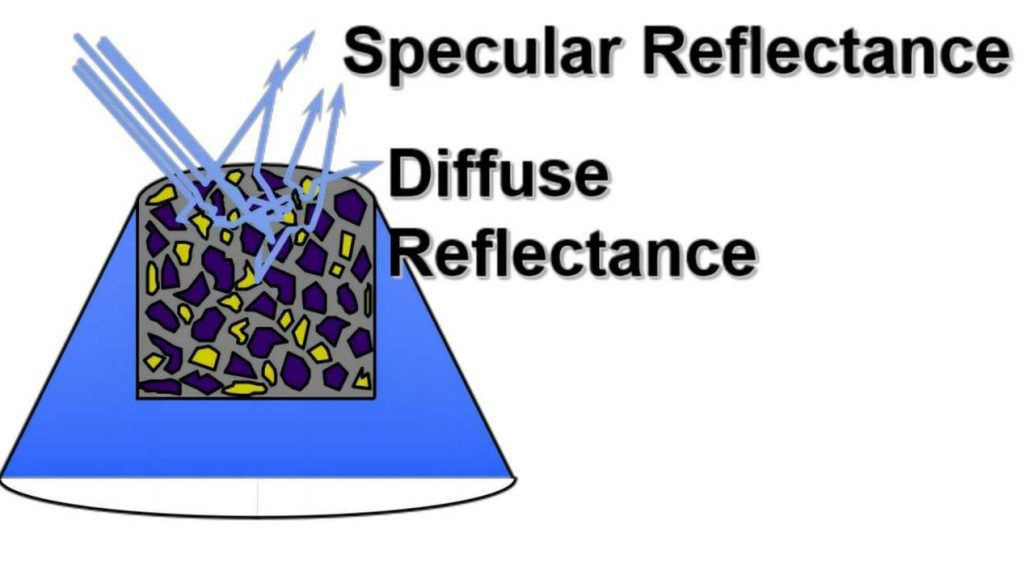

- ATR (Attenuated Total Reflectance): This non-destructive technique uses a crystal to press the sample against and directly measures the reflected IR radiation. It’s perfect for rough surfaces or sensitive materials.

- Microtomy: For analyzing specific regions within a polymer sample, microtoming allows for thin sections to be prepared for FTIR analysis.

FTIR Spectra and Compositional Decoding

Once the sample is ready, the FTIR spectrometer bathes it in a spectrum of infrared radiation. Different functional groups within the polymer molecules absorb specific wavelengths of this light, like dancers responding to certain musical notes. By measuring the absorbed wavelengths, we can create an FTIR spectrum, a unique fingerprint of the polymer’s chemical makeup.

Each peak in the spectrum corresponds to a specific functional group vibration, like the C-H stretch, N-H bend, or C=O carbonyl stretch. By comparing the spectrum to a library of known polymers or using specialized software, we can identify the polymer type and even determine the presence of additives or contaminants.

Polymer’s Structural Secrets Revealed

The information gleaned from the FTIR spectrum goes beyond just identifying the polymer type. It can also provide insights into the polymer’s structure:

- Degree of polymerization: The intensity of certain peaks can indicate the average length of the polymer chains.

- Crystallinity: The presence or absence of sharp, well-defined peaks can reveal whether the polymer is amorphous or has a crystalline structure.

- Branching and cross-linking: The presence of additional peaks or changes in peak shapes can be indicative of branching or cross-linking in the polymer.

Assessing Consistency:

Once we have the FTIR spectrum, several aspects can be compared to ensure consistency:

- Peak positions and intensities: Consistent processing and composition will result in identical peak positions and intensities in the spectrum. Deviations might indicate changes in functional group concentrations or variations in crystallinity or chain orientation.

- Baseline noise: A low and consistent baseline suggests a pure and homogeneous sample. Increased noise might indicate the presence of impurities or contaminants.

- Spectral libraries: Comparing the sample spectrum to established libraries of known polymer spectra helps confirm composition and identify any inconsistencies.

Applications in the Polymer Industry:

FTIR plays a crucial role in various aspects of the polymer industry:

- Quality control: Identifying raw materials, monitoring production processes, and ensuring final product consistency.

- Failure analysis: Investigating the cause of material failures by identifying changes or contaminants in the polymer structure.

- Formulation optimization: Fine-tuning polymer formulations by analyzing the impact of additives and processing conditions on composition and properties.

- Polymer identification: Differentiating between different types of polymers, especially in recycled materials.

Conclusion:

FTIR spectrophotometry is a valuable tool for the polymer industry, providing unparalleled insights into the composition and structure of these materials. By analyzing the “fingerprint” revealed by the infrared light, we can ensure the consistency of polymer materials, leading to improved product quality, reliability, and safety. As research and development continue to refine FTIR techniques, its role in safeguarding the integrity of polymers will only become more essential.