Whether it’s paints, adhesives, pharmaceutical formulations, or food products, precise control over viscosity is essential for ensuring product quality, performance, and consistency. However, traditional viscosity measurement methods often fall short when it comes to high-throughput screening of viscosity-sensitive materials. Digital viscometers are emerging as indispensable tools for the analysis in high-throughput screening(HTS) of viscosity-sensitive materials.

Understanding Digital Viscometers

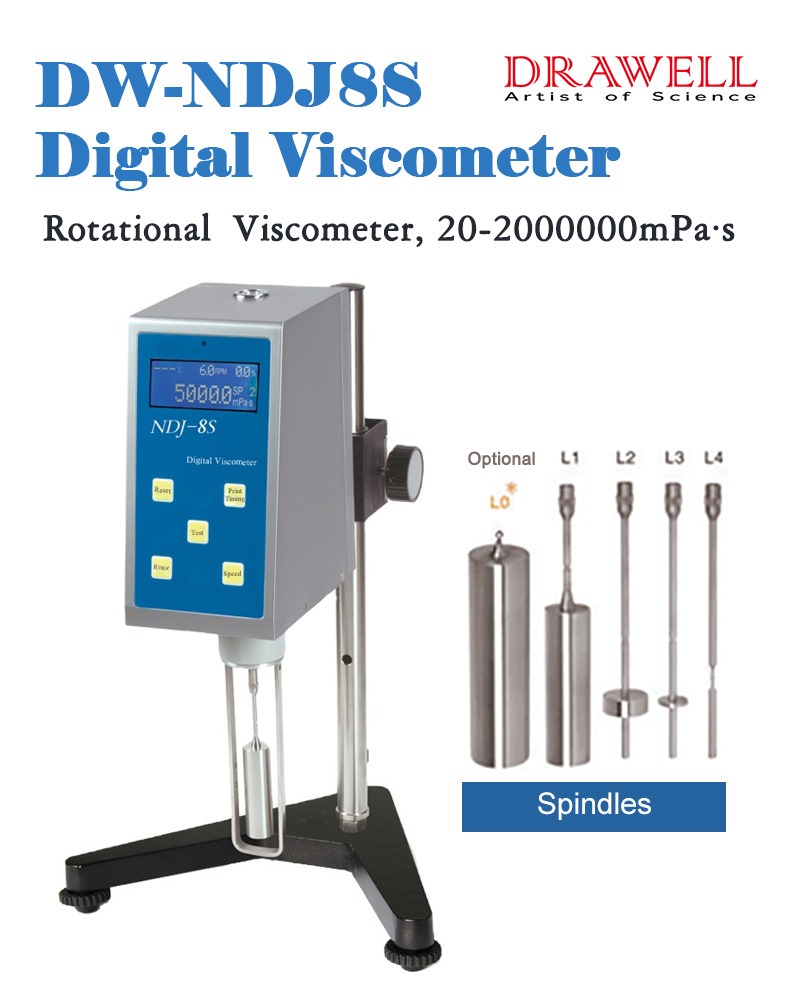

Digital viscometers are advanced instruments designed to measure the viscosity of fluids accurately and efficiently. Unlike conventional viscometers that rely on manual or analog methods, digital viscometers employ sophisticated electronic sensors and data processing algorithms to provide precise viscosity measurements in real-time. These instruments offer a range of features, including automated operation, customizable measurement parameters, and digital data output, making them ideal for high-throughput screening applications.

The Role of Digital Viscometers in High-Throughput Screening

High-throughput screening process involves rapidly testing large numbers of samples to identify compounds or formulations with desired properties. In the realm of viscosity-sensitive materials, such as polymers, surfactants, and emulsions, digital viscometers have become essential tools, revolutionizing the HTS process.

1. Rapid and Accurate Measurement

Digital viscometers offer swift and precise viscosity measurements, essential for analyzing viscosity-sensitive materials efficiently. Traditional methods often require manual intervention and are time-consuming. Digital viscometers automate the process, providing accurate measurements in a fraction of the time, thus expediting the screening process significantly.

2. Customization for Diverse Samples

Viscosity-sensitive materials encompass a broad spectrum of substances with varying properties. Digital viscometers provide flexibility in measurement parameters, allowing researchers to tailor protocols to suit the specific characteristics of each sample. Parameters such as shear rate, temperature, and measurement range can be adjusted, ensuring optimal conditions for accurate viscosity assessment.

3. Real-time Data Analysis

One of the key advantages of digital viscometers is their ability to provide real-time data analysis. Researchers can monitor viscosity changes as they occur during HTS experiments, enabling immediate adjustments and informed decision-making. This real-time feedback loop enhances the efficiency and reliability of the screening process, facilitating the identification of viscosity trends and anomalies across sample sets.

4. Integration with Automation Systems

Digital viscometers seamlessly integrate with automation systems, further streamlining the HTS workflow. Robotic sample handling, combined with digital viscometry, enables high-throughput screening of large sample libraries with minimal manual intervention. This integration maximizes efficiency, minimizes human error, and accelerates the pace of discovery and development.

5. Data Management and Reporting

Digital viscometers generate digital data outputs that can be easily managed and analyzed. Integration with laboratory information management systems (LIMS) facilitates comprehensive data storage, retrieval, and analysis. Researchers can generate detailed reports, visualize trends, and extract valuable insights from the vast amount of data generated during HTS experiments.

6. Quality Control and Process Optimization

By providing accurate and reproducible viscosity measurements, digital viscometers play a crucial role in quality control and process optimization. Researchers can assess the viscosity profiles of materials at various stages of development, ensuring consistency and performance. This enables the identification of optimal formulations, process parameters, and product specifications, driving efficiency and innovation in research and manufacturing.

Applications Across Industries of Digital Viscometers in High-Throughput Screening

1. Chemical and Petrochemical Industry

- Polymer Research and Development: Digital viscometers are used to screen polymer solutions and melts for viscosity variations, aiding in the development of new polymer formulations and optimizing processing parameters.

- Surfactant Screening: In the production of surfactants, digital viscometers assist in HTS to identify formulations with optimal viscosity profiles for applications such as detergents, cosmetics, and personal care products.

2. Pharmaceutical and Biotechnology Industry

- Drug Formulation Development: Digital viscometers enable high-throughput screening of pharmaceutical formulations to assess viscosity changes during drug development, ensuring optimal drug delivery, stability, and bioavailability.

- Bioprocess Optimization: In biotechnology applications, digital viscometers are used to screen cell culture media, protein solutions, and fermentation broths to optimize bioprocess parameters and ensure consistent product quality.

3. Food and Beverage Industry

- Emulsion Stability Screening: Digital viscometers play a critical role in HTS of food emulsions and suspensions to evaluate stability and texture properties, ensuring product consistency and shelf-life stability.

- Sauce and Dressing Formulation: In the development of sauces, dressings, and condiments, digital viscometers aid in HTS to achieve desired viscosity profiles for optimal product performance and consumer acceptance.

4. Cosmetics and Personal Care Industry

- Cream and Lotion Formulation: Digital viscometers assist in high-throughput screening of cosmetic formulations such as creams, lotions, and gels to ensure desired viscosity, spreadability, and sensory attributes.

- Hair Care Product Development: In hair care applications, digital viscometers are used to screen shampoos, conditioners, and styling products for viscosity variations, contributing to product performance and consumer satisfaction.

5. Paints, Coatings, and Adhesives Industry

- Paint and Coating Formulation: Digital viscometers aid in HTS of paint and coating formulations to achieve optimal viscosity for application, film formation, and coating thickness control.

- Adhesive Screening: In adhesive manufacturing, digital viscometers enable HTS to evaluate viscosity changes during formulation and curing processes, ensuring strong bond performance and adhesive properties.

6. Oil and Gas Industry

- Drilling Fluid Optimization: Digital viscometers assist in high-throughput screening of drilling fluids to assess viscosity variations under different drilling conditions, contributing to efficient drilling operations and wellbore stability.

- Fuel Additive Screening: In fuel additive development, digital viscometers aid in HTS to evaluate viscosity changes and flow properties, ensuring compatibility and performance enhancement in fuel formulations.

Challenges and Future Solutions of Digital Viscometers in High-Throughput Screening

Digital viscometers also face unique challenges that necessitate innovative solutions to meet the evolving demands of modern research and industry.

Challenges in Digital Viscometry for High-Throughput Screening

1. Speed and Throughput Constraints

- Traditional viscometry methods often struggle to keep pace with the high throughput requirements of modern HTS workflows, leading to bottlenecks in data acquisition and analysis.

- The need for rapid viscosity measurements across numerous samples poses a significant challenge for digital viscometers to deliver timely results without compromising accuracy.

2. Sample Volume Limitations

- Many digital viscometers require relatively large sample volumes, which can be prohibitive when working with limited or precious samples in high-throughput screenin applications.

- Addressing the need for reduced sample volumes while maintaining measurement accuracy is a critical challenge for enhancing the efficiency of digital viscometry in HTS.

3. Compatibility with Complex Samples

- HTS often involves the analysis of complex sample matrices, including viscous solutions, suspensions, and emulsions, which can pose challenges for conventional viscometry techniques.

- Ensuring the compatibility of digital viscometers with diverse sample types and properties remains a key challenge in high-throughput screenin, requiring innovative approaches to overcome viscosity measurement limitations.

4. Data Integration and Automation

- Efficient integration of digital viscometers into automated high-throughput screening platforms is essential for streamlining workflow processes and maximizing throughput.

- Challenges arise in seamlessly integrating viscosity data with other analytical outputs and automating data analysis pipelines to expedite decision-making in HTS campaigns.

Future Solutions and Innovations

1. Miniaturization and Microfluidic Integration

Advancements in miniaturized digital viscometry platforms and integration with microfluidic systems hold promise for reducing sample volume requirements and enabling high-throughput viscosity measurements with minimal sample consumption.

2. Sensor Technology and Multi-Parameter Analysis

- Integration of advanced sensor technologies, such as microelectromechanical systems (MEMS) and nanomaterial-based sensors, can enhance the sensitivity and versatility of digital viscometers for HTS applications.

- Future digital viscometers may offer multi-parameter analysis capabilities, enabling simultaneous measurement of viscosity, density, and other rheological properties to provide comprehensive sample characterization.

3. Automation and Data Management Solutions

- Enhanced automation features, including robotic sample handling, real-time data acquisition, and cloud-based data management platforms, can streamline HTS workflows and improve data accessibility and analysis efficiency.

- Integration of artificial intelligence (AI) and machine learning algorithms into digital viscometry software can facilitate predictive modeling, pattern recognition, and automated decision-making in HTS data analysis.

4. Application-Specific Customization

Tailoring digital viscometers to specific HTS applications and sample requirements through customizable measurement protocols, software algorithms, and sensor configurations can enhance their versatility and utility across diverse research domains.

Conclusion

Digital viscometers represent a transformative technology in the high-throughput screening of viscosity-sensitive materials, enabling researchers and manufacturers to accelerate innovation, optimize processes, and ensure product quality in diverse industries. Addressing the challenges and implementing future solutions can unlock their full capabilities, empowering researchers and industries to accelerate discovery, innovation, and product development.