Centrifugation is a critical technique in various scientific and industrial processes, employed to separate components based on density differences. A crucial element in this process is the centrifuge rotor, which directly impacts the centrifugal force exerted on the sample. The correct rotor selection is paramount to achieving optimal separation efficiency, sample recovery, and experimental outcomes. This article delves into the types of centrifuge rotors, factors influencing rotor selection, and best practices for rotor use.

Types of Centrifuge Rotors

Centrifuge rotors are categorized based on their design and orientation. The primary types include:

| Rotor Type | Features | Applications |

| Fixed-Angle Rotors | Tubes held at constant angle (25°-45°) | Pelleting cells, bacteria, nucleic acids |

| High-speed capabilities | ||

| May cause sample spreading along tube walls | ||

| Swinging-Bucket Rotors | Buckets swing out to horizontal position | Density gradient centrifugation, separation of varying density samples |

| Even sedimentation at tube bottom | ||

| Generally operate at lower speeds than fixed-angle rotors | ||

| Vertical Rotors | Tubes held in vertical position | Isopycnic separations |

| Minimize path length for particle travel | ||

| Effective for specific high-speed applications | ||

| Zonal Rotors | Designed for large volumes | Large-scale separations, continuous-flow separations |

| Suitable for industrial applications | ||

| Require specialized equipment and knowledge |

In summary, understanding the distinct applications and features of different centrifuge rotors is essential for optimizing centrifugation processes and achieving accurate and efficient sample separation.

Factors to Consider in Rotor Selection

Choosing the appropriate centrifuge rotor is critical in ensuring the optimal performance of your centrifugation processes. The selection impacts the centrifugal effect, which is vital for achieving desired separation and analysis outcomes. Here’s a detailed exploration of how different rotor choices influence the centrifugal effect:

Rotor Speed and G-Force:

Rotor Speed (RPM):

The speed of the rotor is measured in revolutions per minute (RPM). Higher speeds increase the centrifugal force applied to the sample, enhancing the separation efficiency and reducing the time required.

Relative Centrifugal Force (RCF or G-Force):

RCF is the actual force exerted on the samples, measured in multiples of the earth’s gravitational force (g). It is calculated based on the RPM and the radius of the rotor. A higher RCF leads to more efficient separation of particles, especially for denser or more compact particles.

Rotor Capacity

Sample Volume:

Rotors have varying capacities, which determine the maximum volume of sample that can be processed. High-capacity rotors allow for the centrifugation of larger sample volumes, which is useful in preparative applications. For analytical purposes, smaller capacity rotors may be preferred to maximize the separation resolution.

Number of Tubes:

The number of tubes a rotor can accommodate affects throughput. More tubes mean higher throughput, which is beneficial for large-scale experiments or clinical diagnostics.

Rotor Material

Aluminum: Lightweight and cost-effective. Susceptible to corrosion, especially with high-salt or acidic samples.

Stainless Steel: Highly durable and resistant to corrosion. Heavier than aluminum, which may affect handling and speed limits.

Carbon Fiber Composites: Extremely strong and lightweight. Resistant to corrosion and fatigue, allowing for higher speeds and longer life spans. Typically more expensive.

Rotor Geometry

Radius of Rotation:

The distance from the rotor axis to the bottom of the tube affects the centrifugal force. Larger radii increase the centrifugal force for a given RPM.

Aspect Ratio:

The shape and aspect ratio of the rotor cavities can influence sedimentation patterns. Narrow, deep cavities can result in tighter pellet formation, while wider cavities may spread out the sediment.

Rotor Temperature Control

Refrigeration:

Many centrifuges have temperature control features to maintain the sample at a specific temperature. This is crucial for temperature-sensitive samples, such as proteins, nucleic acids, or live cells. Prevents degradation or denaturation during centrifugation.

Heating:

Some applications require heating, such as when working with certain enzymes or chemical reactions. Controlled heating ensures that samples remain at optimal temperatures for reaction processes.

By carefully selecting the appropriate rotor type, speed, capacity, material, geometry, and temperature control, researchers and technicians can optimize the centrifugal effect to achieve precise and efficient sample separation.

Best Practices for Rotor Use

To ensure optimal performance and longevity of the centrifuge rotor, follow these guidelines:

- Rotor balance: Always balance the rotor properly to prevent vibrations and damage to the centrifuge.

- Overloading: Avoid overloading the rotor beyond its capacity to maintain safety and prevent rotor failure.

- Rotor cleaning: Clean the rotor thoroughly after each use to remove contaminants and prevent corrosion.

- Rotor storage: Store the rotor in a clean, dry place to protect it from damage.

- Regular inspection: Inspect the rotor for cracks, wear, or other signs of damage before each use.

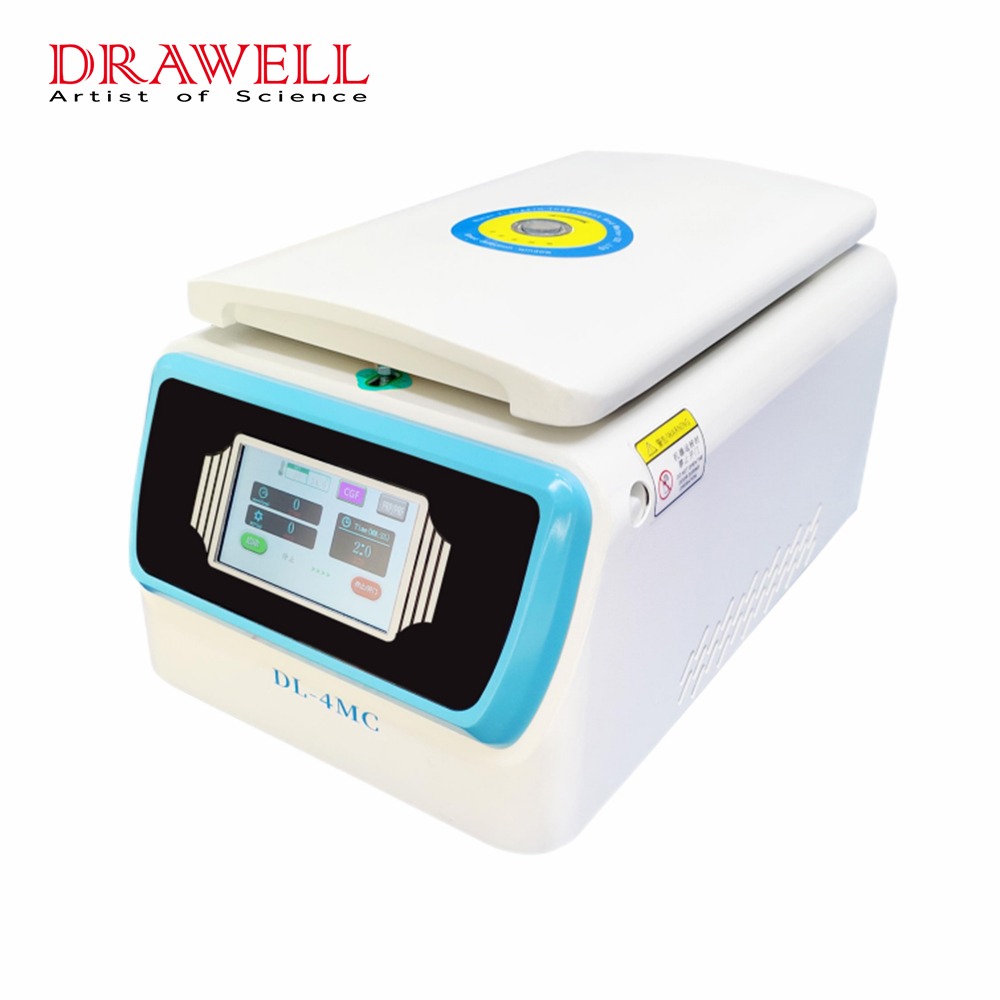

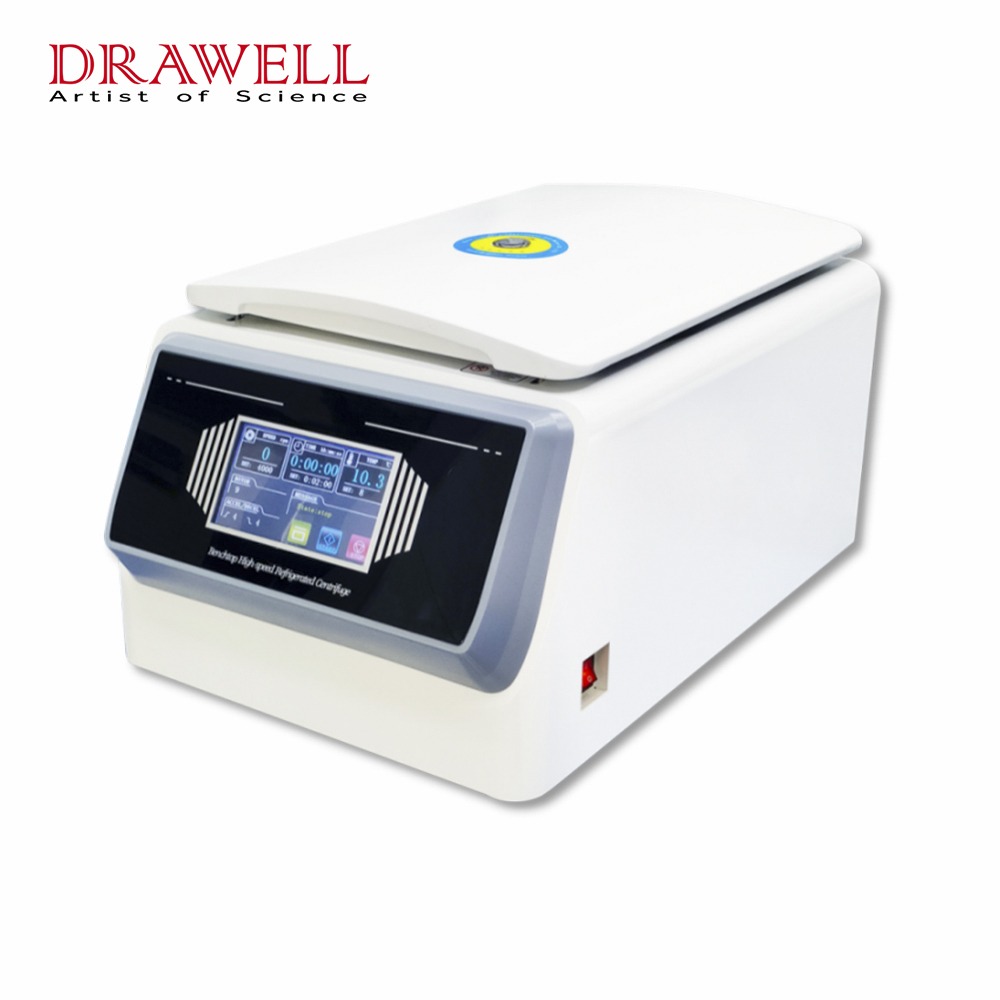

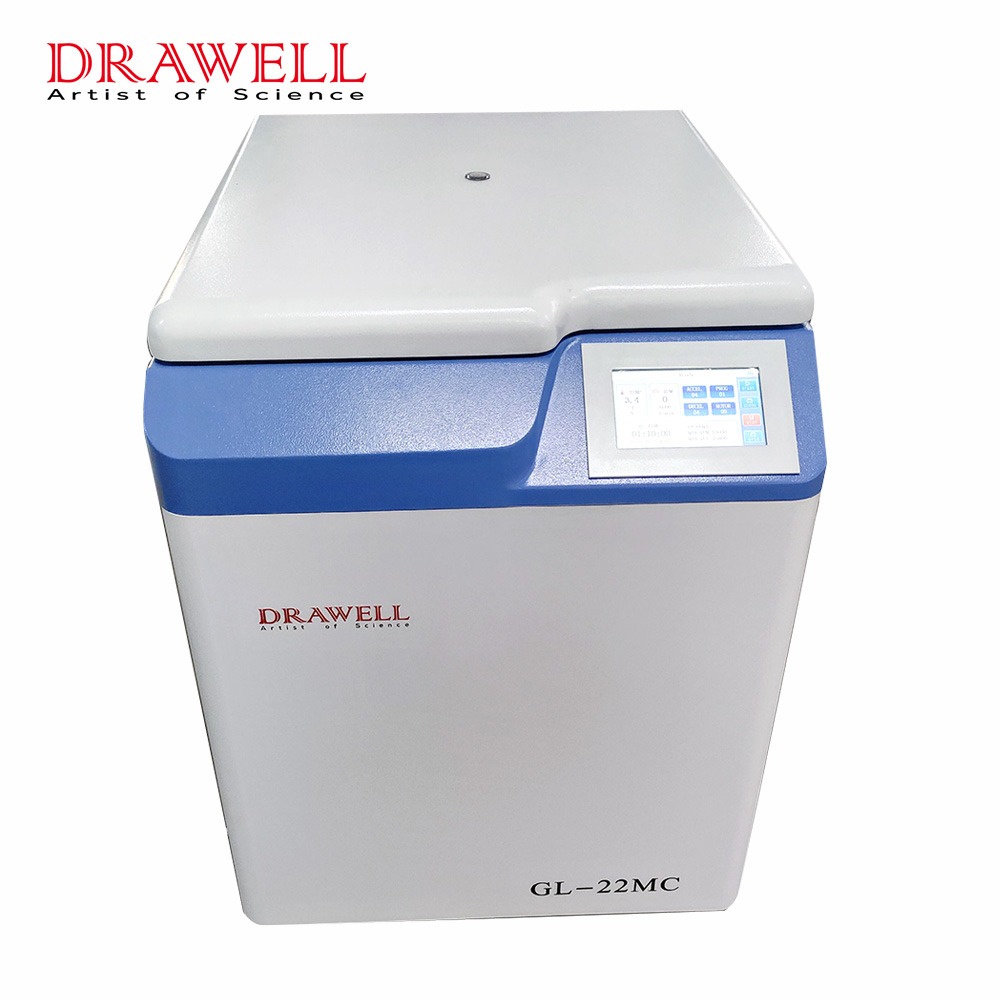

Get Quality Centrifuge and Rotors

Investing in high-quality centrifuges and rotors is crucial for achieving reliable and reproducible results. Drawell is a reputable supplier offering a wide range of centrifuges and rotors tailored to various applications. Their products are known for their durability, precision, and advanced features, ensuring optimal performance and safety in your laboratory.

When selecting centrifuges and rotors from Drawell, any informations about products details like rotor design, material quality, or services like after-sales support, please feel free to contact them. They have professional sales to serve your needs and help you make an informed decision. Reliable equipment from a trusted supplier like Drawell not only enhances the efficiency of your processes but also ensures the safety and integrity of your samples.