In various industries, the precise measurement of moisture content is critical for ensuring product quality, optimizing manufacturing processes, and adhering to regulatory standards. From food and pharmaceuticals to chemicals and construction materials, moisture content affects product stability, consistency, and performance. Traditionally, determining moisture levels involved time-consuming and often labor-intensive methods such as oven drying, infrared analysis, or Karl Fischer titration. However, the advent of automatic moisture analyzers has revolutionized moisture measurement, streamlining processes and enhancing efficiency across diverse sectors.

What are Automatic Moisture Analyzers?

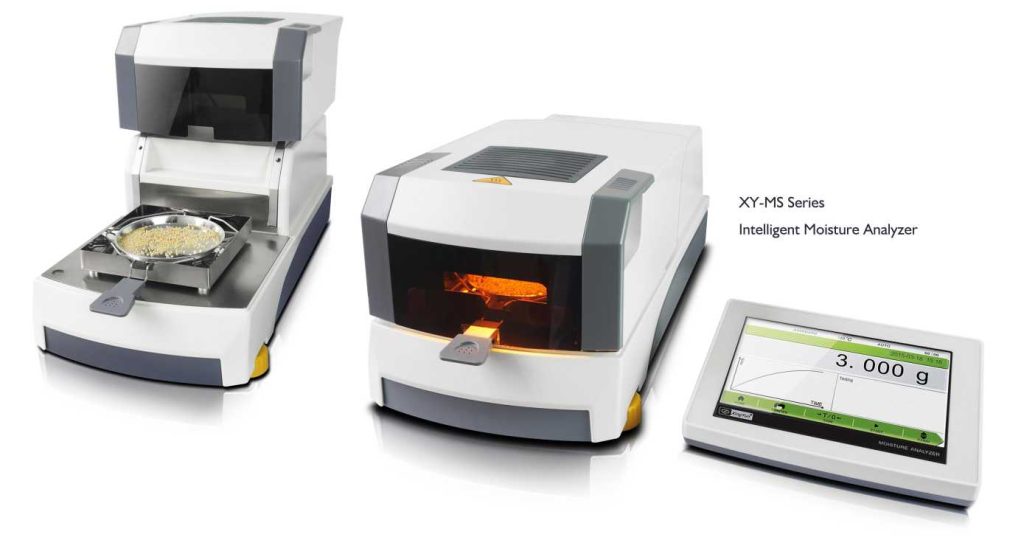

Automatic moisture analyzers, also known as moisture balances or moisture meters, are sophisticated instruments designed to accurately determine the moisture content of a sample quickly and reliably. These devices utilize various techniques such as halogen heating, infrared radiation, or microwave technology to measure moisture levels with precision. Unlike manual methods, automatic moisture analyzers offer several advantages, including speed, accuracy, and ease of use.

Different Types of Automatic Moisture Analyzers

Automatic moisture analyzers come in several types, each employing different principles and technologies for moisture measurement. The main types of automatic moisture analyzers include:

- Halogen Moisture Analyzers: Halogen moisture analyzers use halogen heating elements to evaporate moisture from the sample. These analyzers measure the weight loss of the sample as moisture is removed, allowing for precise determination of moisture content. Halogen moisture analyzers are known for their rapid heating and accurate results, making them suitable for a wide range of applications.

- Infrared (IR) Moisture Analyzers: Infrared moisture analyzers utilize infrared radiation to heat the sample and evaporate moisture. These analyzers emit infrared light that penetrates the sample and causes water molecules to vibrate, leading to the release of moisture. IR moisture analyzers offer fast heating and precise control over the drying process, making them popular in laboratories and industrial settings.

- Microwave Moisture Analyzers: Microwave moisture analyzers use microwave technology to measure moisture content in samples. These analyzers emit microwaves that interact with water molecules in the sample, causing them to heat up and evaporate. Microwave moisture analyzers are known for their rapid heating and deep penetration into the sample, making them suitable for moisture analysis of various materials.

- Near-Infrared (NIR) Moisture Analyzers: Near-infrared moisture analyzers employ near-infrared spectroscopy to measure moisture content in samples. These analyzers analyze the absorption of near-infrared light by molecules in the sample, including water molecules, to determine moisture content. NIR moisture analyzers offer non-destructive analysis and are well-suited for moisture measurement in solid and semi-solid samples.

- Capacitance and Conductance Moisture Analyzers: Capacitance and conductance moisture analyzers measure the electrical properties of the sample to determine moisture content. These analyzers pass electrical currents through the sample and measure the resulting changes in capacitance or conductance, which are correlated with moisture content. Capacitance and conductance moisture analyzers are suitable for a wide range of materials and offer fast and accurate moisture measurement.

- Loss on Drying (LOD) Analyzers: Loss on drying analyzers heat the sample at a controlled temperature until all moisture is removed. The weight loss of the sample before and after drying is used to calculate moisture content. LOD analyzers offer reliable and accurate results for moisture analysis but may require longer analysis times compared to other types of moisture analyzers.

Each type of automatic moisture analyzer has its advantages and limitations, and the choice of analyzer depends on factors such as the type of sample, required accuracy, speed of analysis, and budget considerations. However, all of these analyzers are designed to provide fast, accurate, and reliable moisture measurements across various industries and applications.

How Do Automatic Moisture Analyzers Work?

Automatic moisture analyzers work by employing various technologies and principles to accurately measure the moisture content of a sample. While the exact operation may vary depending on the type of analyzer, the general process typically involves the following steps:

- Sample Preparation:

The sample to be analyzed is prepared according to the requirements of the moisture analyzer. This may involve weighing a specific amount of sample and placing it in a sample pan or container suitable for analysis.

- Heating or Drying:

Once the sample is prepared, the automatic moisture analyzer initiates the drying process. Depending on the type of analyzer, heat may be applied using halogen lamps, infrared radiation, microwaves, or other heating elements. The goal is to evaporate the moisture from the sample while minimizing any impact on the sample’s integrity.

- Weight Measurement:

As the sample is heated and moisture evaporates, the analyzer continuously measures the weight of the sample. This is typically achieved using precision weighing mechanisms that can detect even small changes in weight.

- Moisture Content Calculation:

The analyzer calculates the moisture content of the sample based on the initial weight of the sample and the weight loss observed during the drying process. By comparing the initial and final weights, the percentage of moisture in the sample can be determined using predefined algorithms or calibration curves.

- Data Display and Analysis:

The moisture analyzer displays the results of the analysis in real-time, typically showing the moisture content as a percentage or in other relevant units. Some analyzers may also offer additional features such as data logging, graphical analysis, and statistical calculations to help users interpret and analyze the results.

- Calibration and Verification:

Automatic moisture analyzers require periodic calibration and verification to ensure accuracy and reliability of measurements. Calibration involves comparing the analyzer’s readings to known reference standards, while verification involves testing the analyzer’s performance using certified reference materials or control samples.

- Data Management and Reporting:

Many modern automatic moisture analyzers come equipped with data management features and connectivity options. Users can store analysis results, generate reports, and integrate the analyzer with laboratory information management systems (LIMS) or other digital platforms for data analysis and documentation.

Overall, automatic moisture analyzers streamline the process of moisture analysis by automating the heating, weighing, and calculation steps. By providing fast, accurate, and reliable moisture measurements, these analyzers help industries maintain product quality, optimize production processes, and ensure compliance with regulatory standards.

Streamlining Processes with Automatic Moisture Analyzers

Automatic analyzers streamline processes by leveraging technology to perform tasks with speed, accuracy, and efficiency. Here are several ways in which automatic analyzers streamline processes across various industries:

1. Speed and Efficiency: Automatic moisture analyzers provide rapid results compared to traditional moisture analysis methods such as oven drying or Karl Fischer titration. These analyzers can deliver moisture measurements within minutes, allowing manufacturers to make real-time decisions and adjustments to production processes. This speed enhances overall efficiency and throughput in manufacturing operations.

2. Accuracy and Precision: Automatic moisture analyzers offer high levels of accuracy and precision in moisture measurements. By utilizing advanced technology and precise measurement algorithms, these analyzers minimize errors and variability in moisture analysis results. This accuracy is essential for maintaining product quality, meeting regulatory requirements, and ensuring consistency in manufacturing processes.

3. Versatility and Adaptability: Automatic moisture analyzers are versatile and can accommodate a wide range of sample types and sizes. Whether analyzing powders, granules, liquids, or solids, these analyzers can handle diverse materials encountered in different industries. Moreover, some analyzers offer customizable settings and programmable options, allowing users to tailor the analysis process to specific sample requirements and preferences.

4. Automation and Integration: Automatic moisture analyzers automate the moisture analysis process, reducing the need for manual intervention and oversight. These analyzers often feature built-in data management capabilities and connectivity options, enabling seamless integration with laboratory information management systems (LIMS) and other digital platforms. By automating data capture, storage, and analysis, manufacturers can improve workflow efficiency, enhance traceability, and streamline compliance with regulatory standards.

5. Non-Destructive Testing: Many automatic moisture analyzers offer non-destructive testing capabilities, allowing manufacturers to preserve valuable samples for further analysis or archival purposes. Unlike traditional methods that may require sample destruction, automatic analyzers enable moisture measurements without altering the sample’s integrity. This non-destructive approach minimizes waste, reduces the need for additional sample preparation, and optimizes resource utilization in the manufacturing process.

5. Real-Time Monitoring and Control: Automatic moisture analyzers facilitate real-time monitoring and control of moisture levels during production processes. By continuously measuring moisture content, manufacturers can identify deviations from target specifications and take corrective actions promptly. This proactive approach helps prevent quality issues, minimize production downtime, and optimize resource utilization, ultimately enhancing overall process efficiency and product consistency.

Overall, automatic moisture analyzers play a crucial role in streamlining manufacturing processes across industries by offering speed, accuracy, versatility, and automation in moisture analysis. By leveraging these benefits, manufacturers can achieve higher levels of efficiency, quality, and compliance in their operations, ultimately driving competitiveness and success in today’s dynamic marketplace.

Conclusion

Automatic moisture analyzers represent a significant advancement in moisture analysis technology, offering speed, accuracy, and versatility across a wide range of industries and applications. By streamlining moisture measurement processes, these instruments empower manufacturers to enhance product quality, optimize production efficiency, and ensure regulatory compliance. As industries continue to evolve and innovate, automatic moisture analyzers will remain indispensable tools for maintaining excellence and competitiveness in today’s dynamic marketplace.