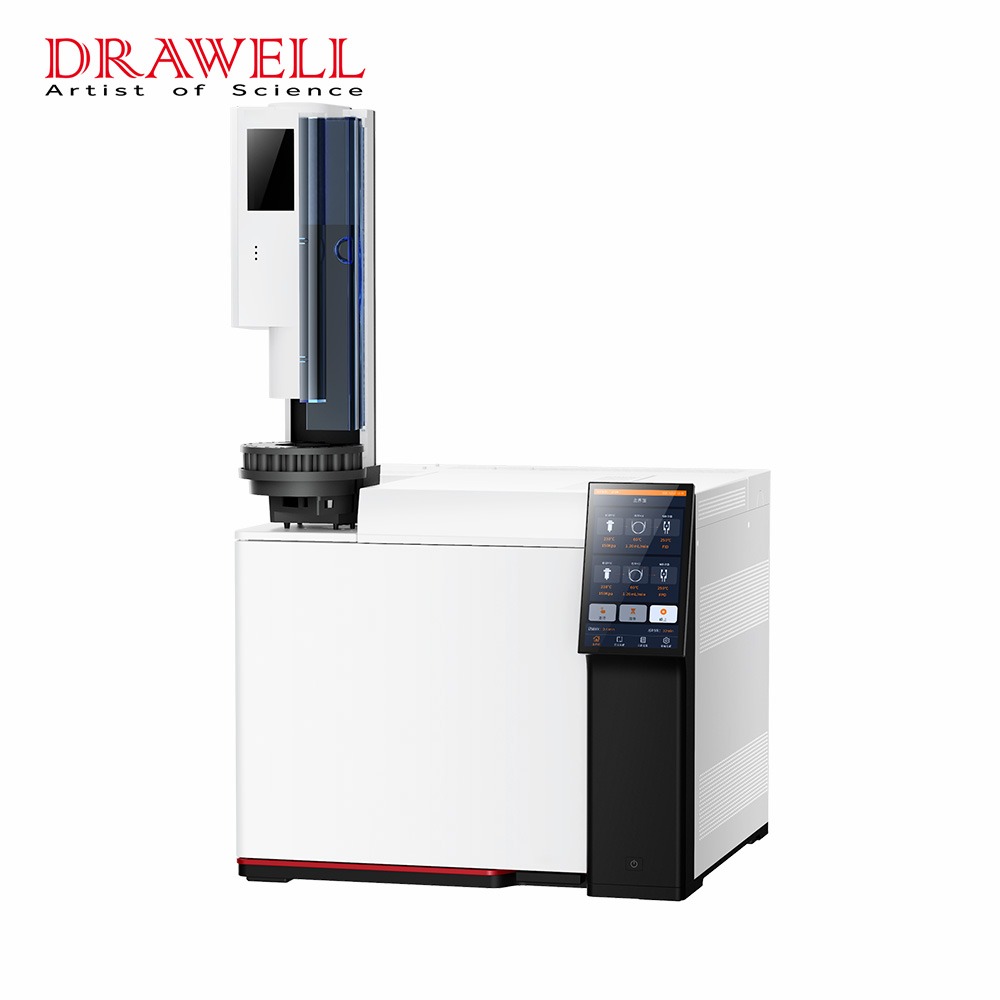

GC2000 Gas Chromatograph

- A trustworthy partner

The new-generation GC2000 gas chromatograph is benchmarked against international leading brands, and the instrument adopts advanced electronic flow control, microfluidic plate control, high-precision independent temperature control and other technologies to meet the user’s requirements for strong analytical capabilities and reliable stability.

- A smart application expert near you

The new-generation GC2000 has intelligent functions such as self-diagnosis, self-leak detection, self-saving of carrier gas, automatic reminders, etc., which help you easily grasp the instrument status and solve problems quickly. It can be matched with various pretreatment equipment such as solid phase microextraction, headspace, liquid sampler, etc. to meet your needs for more application expansion.

Features of GC2000 Gas Chromatograph

- Ultra-stable liquid injection port

- Ultra-high-precision electronic pressure controller (EPC)

- World-class column oven

- User-friendly workstation software

- Excellent human-computer interaction experience

- Supporting multiple detector options (up to four at the same time)

Specifications of GC2000 Gas Chromatograph

| 1. System Performance | |

| Peak area repeatability | < 0.5% RSD; |

| Retention time repeatability | < 0.008% RSD; |

| 2 injection ports, 4 detectors and 3 detector signals can be installed at the same time. All inlet, detector and auxiliary gas path are controlled by electronic flow path, support pressure and temperature compensation; | |

| *The instrument can be upgraded to gas chromatography-single quadrupole mass spectrometer and gas chromatography-triple quadrupole mass spectrometer of the same brand as gas chromatograph. | |

| The detector uses electronic digital data output; | |

| ≥6 electronic flow control modules can be installed at the same time to provide ≥18 gas path control; | |

| There are 4 separate heating zones (excluding column oven). | |

| 2. Environmental Conditions | |

| Ambient operating temperature range | 5℃~35℃ or wider; |

| Ambient working humidity range | 5%-95%RH or wider; |

| Power supply requirements | 220 V±10%, 50 Hz±10%; |

| 3. Column Oven | |

| Temperature control range | room temperature +4℃~450℃ or wider; |

| Temperature setting accuracy | ≤0.1℃; |

| Temperature control accuracy | ≤0.01℃ |

| *Program level | 31 level /32 platform, can achieve program temperature and program cooling; |

| Maximum heating rate | ≥120 ℃/min; |

| Cooling rate | from 450℃ to 50℃ (room temperature 20℃) ≤6 min; |

| The ambient temperature changes by 1℃, and the average temperature of column temperature chamber changes by < 0.01℃. | |

| 4. Electronic Pressure Flow Controller (EPC) | |

| *Ruby damper; | |

| Pressure control accuracy | ≤± 0.001psi; |

| The pressure unit can be psi, kpa, bar; | |

| Gas path control mode | constant pressure, constant current, program boost and program lift steps ≥4 steps, can calculate the column average linear velocity; |

| Pressure control range | 0~100 psi or wider; |

| Flow monitoring range | Nitrogen 0~500 mL/min or wider, hydrogen or helium 0~1000 mL/min or wider. |

| 5. Split/splitless Inlet | |

| Maximum operating temperature | ≥450℃; |

| Temperature setting accuracy | ≤0.1℃; |

| Maximum split ratio | ≥ 1:12,500; |

| The sample inlet has automatic leak detection function; | |

| The injection modes can be split, splitless, pulse split, pulse splitless, etc. | |

| Applicable to all capillary columns (inner diameter 0.1mm ~ 0.53mm); | |

| The injector spacer and split plate can be replaced by manual maintenance without tools. | |

| 6. Detector | |

| Hydrogen Flame Ionization Detector (FID) | |

| Maximum operating temperature | ≥450℃; |

| Detection limit | <5×10-12 g C/s; |

| Linear range | ≥107; |

| Signal acquisition frequency | ≥200 Hz; |

| With automatic ignition function and flameout protection function; | |

| Hydrogen leakage protection. | |

| Flame Photometric Detector (FPD) | |

| Maximum operating temperature | ≥350℃; |

| Detection limit | <9×10-14 g/s (P), 5×10-12 g/s (S); |

| Linear range | ≥104 (P), ≥103 (S); |

| Signal acquisition frequency | ≥200 Hz; |

| With automatic ignition function and flameout protection function; | |

| With automatic ignition function and flameout protection function; | |

| Hydrogen leakage protection function. | |

| Electron Capture Detector (ECD) | |

| Maximum operating temperature | ≥350℃; |

| Detection limit | <3.8×10-14 g/ml; |

| Signal acquisition frequency | ≥200 Hz. |

| Thermal Conductivity Detector (TCD) | |

| Maximum operating temperature | ≥350℃; |

| Detection limit: < 8.7×10-6 g/ml; | |

| Linear range | ≥104; |

| Signal acquisition frequency | ≥200 Hz. |

| 7. Assistant EPC Module | |

| Pressure control range | 0~100 psi or wider; |

| Pressure control accuracy | ≤± 0.001psi. |

| 8. Host Display | |

| *≥8 inches high resolution full color full touch capacitive screen, built-in intelligent operating system; | |

| The host control software is customized based on Android system, graphical UI, and intelligent functions such as self-diagnosis and reminder, self-leak detection, and carrier gas self-saving. | |

| 9. Workstation Software | |

| *Independent research and development software, according to user needs to develop special software; | |

| Collection software and analysis software can be installed separately and work independently. The workstation software occupies less than 1 GB of memory. | |

| The analysis software has the functions of data screening, batch processing, automatic calculation of statistical data, and drawing trend chart. | |