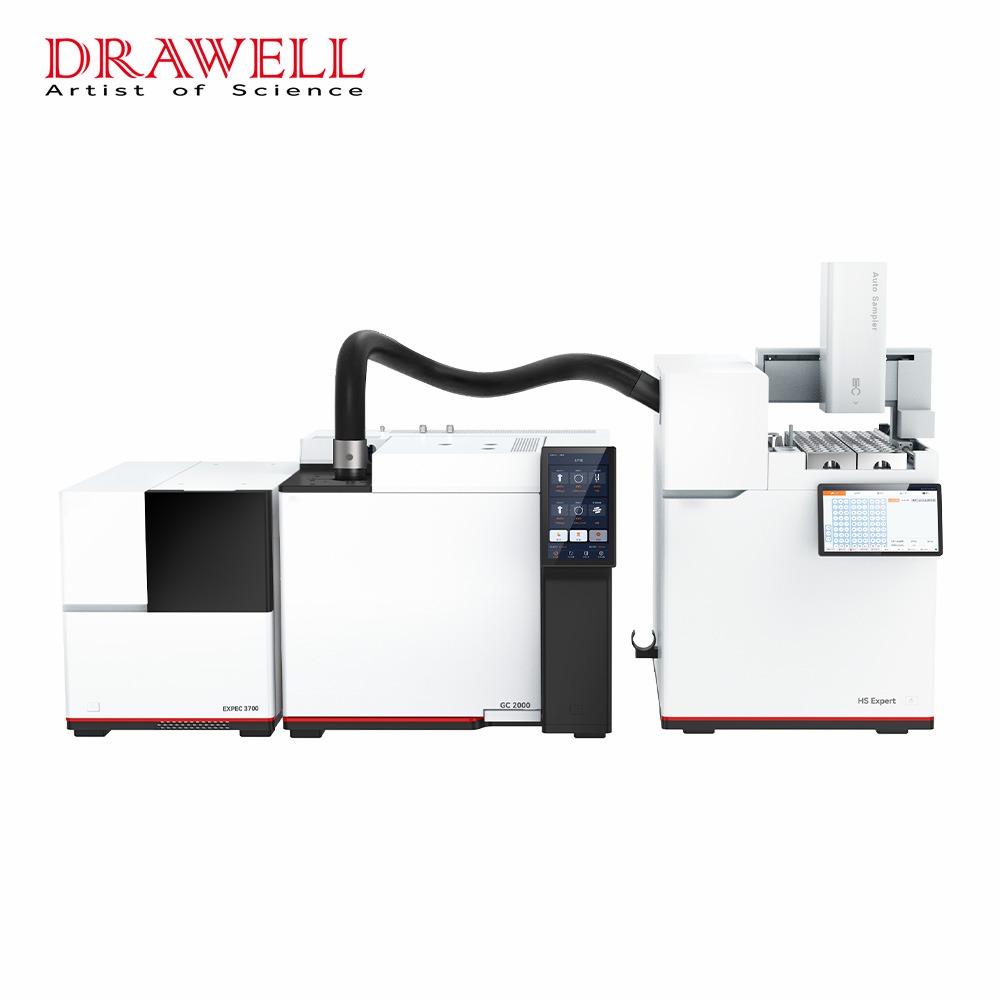

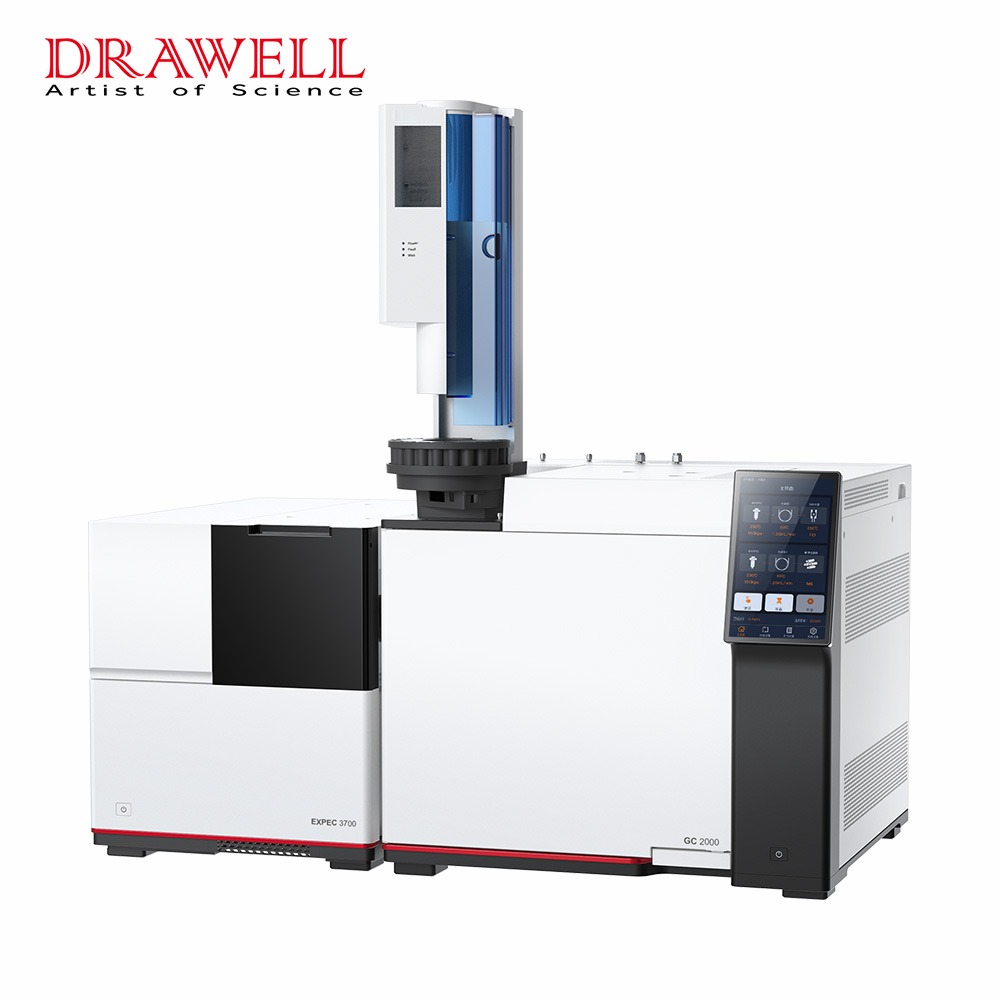

GC-MS DW-EXPEC3700 Gas Chromatography-Quadrupole Mass Spectrometer

DW-EXPEC3700 is a special-purpose detection and analysis instrument for laboratories based on the basic principle of Gas chromatography mass spectrometry. It adopts the advanced electronic flow pressure control system, microfluidic plate control technology, high-precision independent temperature control system, and high-sensitivity MS detector, meet the user’s requirements for the capability, reliability, stability and advanced nature of instrument analysis.

Features of GC-MS DW-EXPEC3700

- Inheritance to the classic workstation without changing the usage habits.

- Self-developed high-precision analytical quadrupole.

- Durable and highly-sensitive detector.

- Ultra-stable liquid injection port.

- Ultra-high precision electronic flow controller (EPC).

- Outstanding human-machine interaction experience.

Applications of GC-MS DW-EXPEC3700

laboratory and vehicle-mounted scenarios:

With the excellent anti-seismic design, the DW-EXPEC3700 is easy to be deployed on the vehicle, free from the impact of bumps on the analysis results.

A vacuum environment can be created in an ultra-efficient manner for immediate measurement after the parking, saving the valuable time.

Specifications of GC-MS DW-EXPEC3700

| GC | |

| Chromatographic performance | |

| Peak area repeatability | < 0.5%. |

| Retention time repeatability | < 0.008%. |

| 8-inch high-resolution full-color capacitive touch screen. | |

| Customized host control software based on the Android system, with the graphical interface in Cheese, full touch for operation, the UI also graphical, in combination with intelligent functions such as self-diagnosis reminder, self-leakage detection, etc., reducing the difficulty of use and maintenance, and for easily grasping of the status of the instrument. | |

| Column oven | |

| Temperature range applicable to all columns and their separation requirements. | |

| Room temperature | Room temperature +4℃-450℃. |

| Temperature setting accuracy | ≤0.1℃. |

| Supporting 32 oven heating gradients,33 constant temperature platforms, and possible to realize programmed temperature rise and programmed temperature rise. | |

| Maximum hearting rage | ≥120℃/min. |

| Oven cooling rate | 6 min from 450℃ to 50℃,at a room temperature of 20℃. |

| Ambient temperature sensitivity | 1℃ change in ambient temperature, change in column oven average temperature <0.01 ℃. |

| Electronic gas circuit control | |

| Standardized pressure and temperature compensation functions. | |

| Electronic pressure control with ruby damping, with pressure control accuracy at ± 0.001 psi. | |

| Pressure units are available in psi、kPa、bar; | |

| Programed pressure rise/flow rise | Up to forth order. |

| Supported carrier and makeup gas types | N2, He, H2. |

| Stability of carrier gas flow rate | Less than1%/10 min. |

| Injection port | |

| Supports installation of up to two injection ports. | |

| Fully electronic gas circuit control, supporting pressure compensation and temperature compensation. | |

| Injection port type | Standard split/split less injection port, ultra-deactivated split/split less injection port. |

| Compatible with all capillary columns(inner diameter:0.1mm-0.53mm) . | |

| Split ratio up to 12500:1 to avoid column overload. | |

| Supporting, split ,split less, pulse spilt, pulse split less injection and other injection modes. | |

| Maximum operating temperature | 450℃. |

| Temperature setting accuracy | ≤0.1℃. |

| Carrier gas saving mode, making it possible to reduce gas consumption without compromising chromatographic separation effects. | |

| Electronic septum purge flow control to effectively eliminate chromatographic ghost peaks. | |

| Flow control range 0-500mL/min(N2),0-1000mL/min(H2 or He). | |

| Injection port supporting ultra-deactivated processing, eliminating active sites on surface and improving detection sensitivity, peak shape and reproducibility of active substances. | |

| QMS | |

| Transfer-line | |

| Transfer-line temperature 50-400 ℃ without cold point. | |

| Ion-source | |

| Dual-filament high efficiency EI source, inert material. | |

| High sensitivity ion source with increased ionization efficiency. | |

| Positives/negative CI source. | |

| Emission | 0-300μA |

| Ionization energy | 0-240eV |

| Ion source temperature | 50-350℃. |

| Ion source cleaning gas available with flow rate of 0-5sccm. | |

| Quadrupole | |

| High precision Mo quadrupole without temperature control. | |

| Pre-rod used to decrease fringing field effect and the contamination of the main rod. | |

| Mass range | 1.5u-1200u |

| Mass Resolution | unit mass resolution |

| Mass Stability | ±0.10u/48h |

| Sensitivity | Inert ion source:1pg(OFN),S/N≥1500:1 SIP: 100 fg(OFN),S/N≥300:1 NCI: 200 fg(OFN),S/N≥2000:1 PCI: 100 pg(BZP),S/N≥1200:1 |

| Maximum scanning speed | 20000u/s. |

| Side-opening-board design. Maintenance of the ion source without the disassembly of the columns. | |

| Detector | |

| Long-life channel EM | |

| Triaxial ion path detector to decrease the influence of neutrals | |

| Dynamic range | ≥107 |

| Vacuum system | |

| Vacuum system of Mechanical pump and turbopump (250L/s of He) | |

| Vacuum lock system to decrease the time of vacuum condition setting up (10^-4Pa in 20min). Vacuum keeping under electricity outage. | |