Laminar flow cabinets are essential in laboratories and cleanrooms for maintaining a sterile and controlled environment. They are intended to provide a continuous flow of filtered air, reducing the risk of contamination during critical procedures. Pharmaceutical, biotechnology, electronics, and healthcare industries all use laminar flow cabinets. In this article, we discuss the topic of types of laminar flow cabinet, exploring the different types of laminar flow cabinets, their applications, and the key factors to consider for choosing the right type of laminar flow cabinet.

Common Types of Laminar Flow Cabinets

1. Horizontal Laminar Flow Cabinets

In horizontal laminar flow cabinets, air flows horizontally from the back of the cabinet to the front. This design is suitable for applications where the product or samples need protection from airborne contaminants.

Horizontal laminar flow cabinets are frequently used in medical laboratories, research facilities, and industries where sensitive materials are handled.

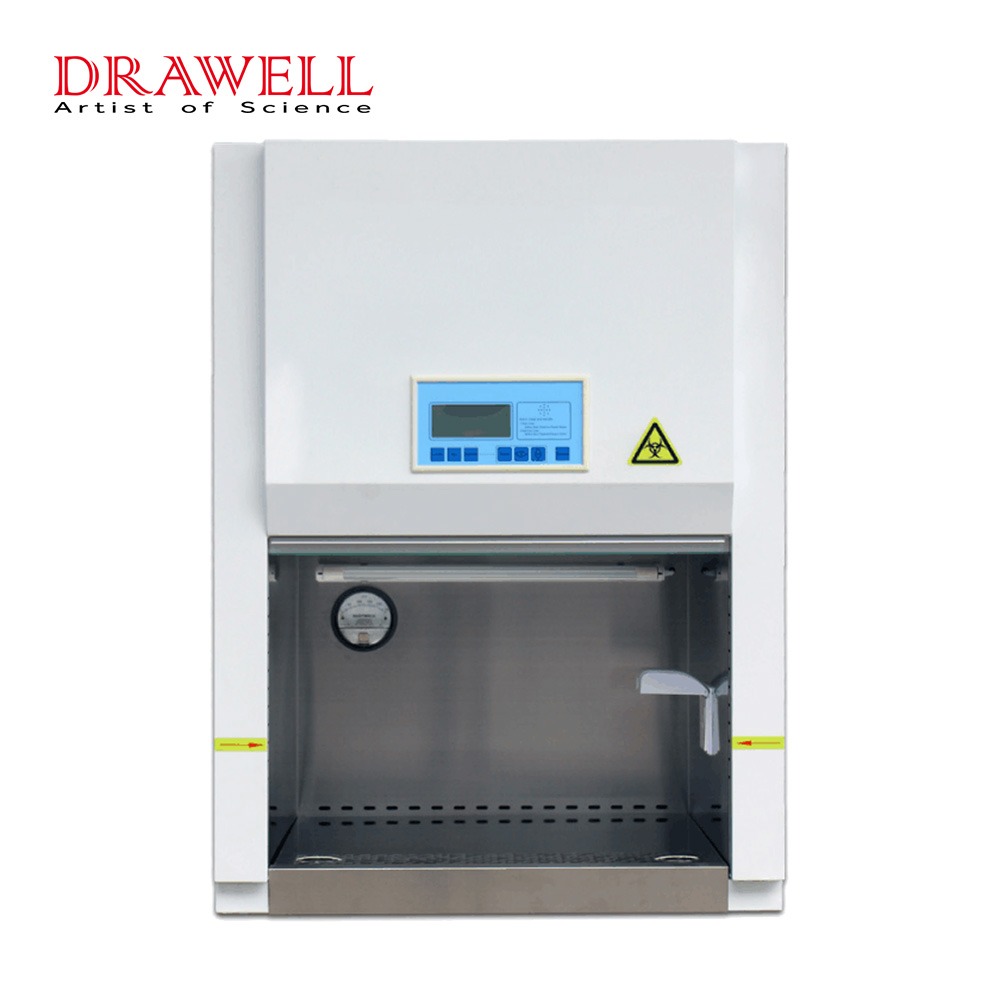

2. Vertical Laminar Flow Cabinets

Vertical laminar flow cabinets use a vertical airflow pattern to ensure that contaminants are removed from the work surface quickly and do not settle on the materials.

These cabinets are ideal for applications such as electronics manufacturing and assembly, where the emphasis is on protecting the product or samples from airborne particles.

3. Ducted Laminar Flow Cabinets

Ducted laminar flow cabinets are linked to an external ventilation system, which allows exhaust air to be removed. This type of cabinet is appropriate for applications where it is necessary to exhaust specific fumes or particles in order to maintain a clean and safe working environment.

4. Ductless Laminar Flow Cabinets

External ventilation is not required for ductless laminar flow cabinets, also known as recirculating cabinets. Instead, they use HEPA or ULPA filters to capture and purify the air within the cabinet.

Ductless cabinets are more flexible in terms of installation, as they do not need to be connected to an external exhaust system. They are often used in facilities where external venting is challenging.

5. Portable Laminar Flow Cabinets

Portable laminar flow cabinets are small and mobile, making them ideal for fieldwork or situations requiring mobility.

These cabinets are frequently used for on-site sampling, testing, and other applications that require a controlled environment away from a traditional laboratory setting.

6. Customized Laminar Flow Cabinets

Certain applications may necessitate features or configurations that are not available in standard laminar flow cabinets. In such cases, customized laminar flow cabinets can be designed to meet the user’s specific requirements.

Customization may include changes in size, material, airflow velocity, and other features tailored to the application’s specific needs.

Key Factors to Consider for Choosing the Right Type of Laminar Flow Cabinets

It is critical to choose the correct type of laminar flow cabinet to ensure the success of laboratory processes and to maintain a clean and controlled working environment.

1. Type of Application

The requirements for cleanliness and sterility vary depending on the application. Consider the job at hand, such as sample preparation, cell culture, electronics assembly, or pharmaceutical compounding. Depending on the application, the type of laminar flow cabinet required may differ.

2. Airflow Direction

Determine whether the application requires a horizontal or vertical laminar flow cabinet. Horizontal flow is frequently preferred for applications where product or sample protection is critical, whereas vertical flow is advantageous when the emphasis is on protecting the work surface from contaminants.

3. Cleanliness Class

Laminar flow cabinets are classified into ISO classes based on the level of cleanliness they provide. ISO 5 is the cleanest, and as the number increases, the cleanliness level decreases. Choose a cabinet with an ISO class that aligns with the sensitivity of the work being conducted.

4. Airflow Velocity

The airflow velocity within the laminar flow cabinet is crucial for maintaining a clean environment. Consider the required velocity based on the application. Higher velocities are typically needed for applications where a higher level of cleanliness is essential.

5. Ducted vs. Ductless

Decide whether a ducted or ductless laminar flow cabinet is more suitable. Ducted cabinets are connected to an external ventilation system and are suitable for applications where fumes or particles need to be exhausted. Ductless cabinets use internal filtration systems and are more flexible in terms of installation.

6. Mobility and Size

Consider the size of the laminar flow cabinet based on the workspace available. In some cases, a portable or smaller cabinet may be more appropriate, especially for fieldwork or situations where mobility is essential.

7. Installation Requirements

Determine the installation requirements of the laminar flow cabinet. Some cabinets may need to be installed in a specific location with access to external ventilation, while others can be more easily placed in various settings.

8. Budget Considerations

The cost of laminar flow cabinets can vary based on their features and specifications. Consider the budget constraints and balance them with the necessary features required for the application.

9. Regulatory Compliance

Check that the laminar flow cabinet you choose complies with industry regulations and standards. This is especially important in industries such as pharmaceuticals and healthcare, where strict regulatory requirements must be met.

10. Customization Options

Consider whether customization options are available if standard laminar flow cabinets do not meet specific requirements. Custom cabinets can be designed to meet specific specifications and needs.

Conclusion

Understanding the various types of laminar flow cabinets and their applications is critical for maintaining a clean and controlled environment in a variety of scientific and industrial settings. The selection of the proper type of laminar flow cabinet is critical to the success of laboratory processes and experiments.