Laboratory analytical balances are indispensable tools in scientific research, quality control, and various analytical processes. Their ability to measure the mass of substances with exceptional precision is critical in ensuring accurate results across a spectrum of industries. From pharmaceuticals to nanotechnology, these balances come in various types, each catering to specific needs and requirements. This article aims to delve into the world of laboratory analytical balances, exploring their various types, applications, proper handling, and maintenance.

Classification of Laboratory Analytical Balances

Analytical balances can be categorized in different ways based on their precision and mechanism. Precision-based classification includes microbalances, ultra-microbalances, semi-microbalances, and analytical balances. Microbalances and ultra-microbalances are designed for weighing extremely small quantities, making them vital in fields like nanotechnology and pharmaceutical research. Semi-microbalances strike a balance between precision and capacity, finding applications in both chemical and biological laboratories. Analytical balances, falling within the standard precision range, are commonly used for quality control and routine analysis.

Mechanism-based classification encompasses electronic balances and mechanical balances. Electronic balances utilize advanced technology for precise measurements, with digital readouts and data handling capabilities. On the other hand, mechanical balances employ a lever-arm mechanism for comparative weighing and are still used in certain applications today due to their historical significance and simplicity.

Types of Laboratory Analytical Balances

A. Microbalances

Microbalances are the epitome of precision, capable of measuring masses as small as a few micrograms. These balances are essential for nanotechnology and pharmaceutical research, where small quantities of substances can have significant impacts. Handling microbalances requires a controlled environment to minimize external influences on measurements.

B. Ultra-Microbalances

Ultra-microbalances take precision to another level, enabling the measurement of sub-microgram quantities. These balances find application in molecular research and material science, where the analysis of minute quantities is crucial. Ultra-microbalances demand meticulous handling and are typically operated in environments with minimal vibrations and controlled temperature and humidity.

C. Semi-Microbalances

Semi-microbalances strike a balance between precision and capacity. They are often used in chemical and biological laboratories for weighing larger samples with high accuracy. Semi-microbalances are versatile tools in analytical chemistry, enabling the accurate preparation of solutions and samples for further analysis.

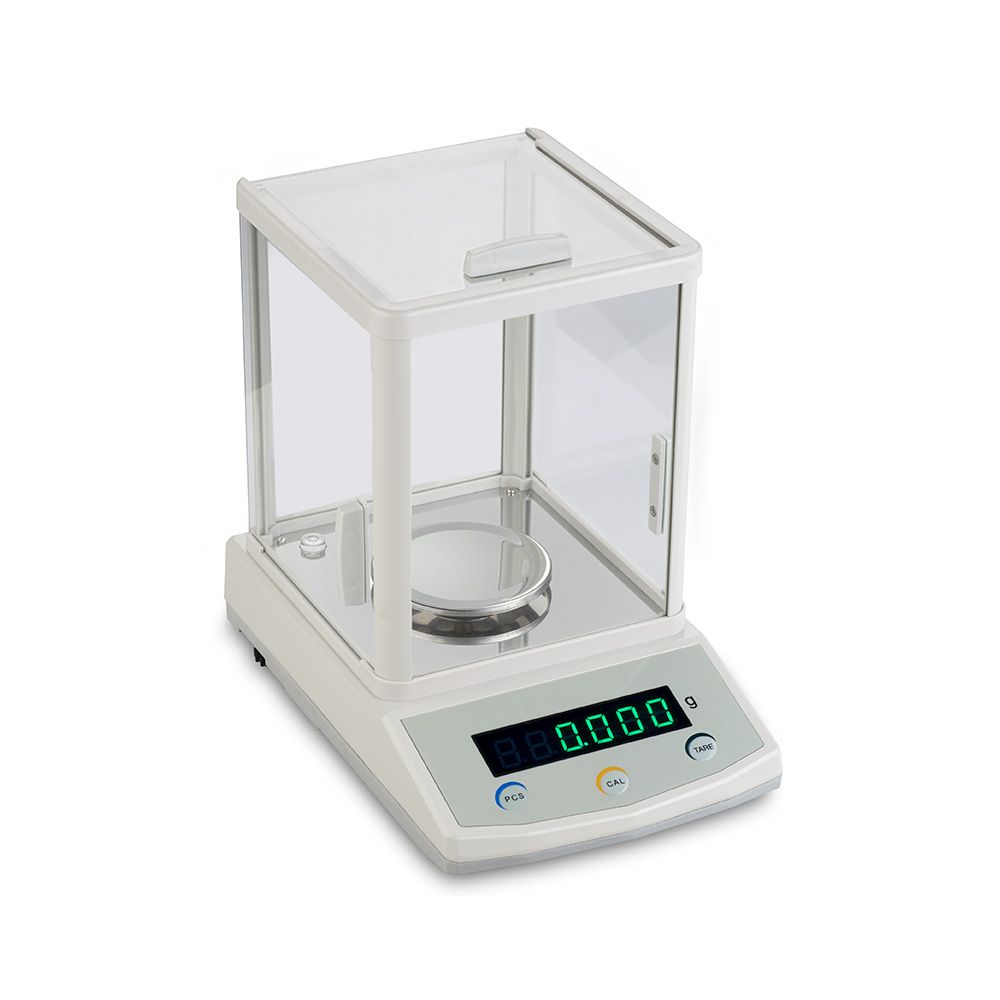

D. Analytical Balances

Analytical balances are the workhorses of laboratories, offering a standard level of precision suitable for routine analysis and quality control. They are commonly used across industries to determine the concentration of substances, ensure product quality, and maintain consistency in manufacturing processes. Regular calibration and proper handling are crucial to ensure the accuracy of analytical balances.

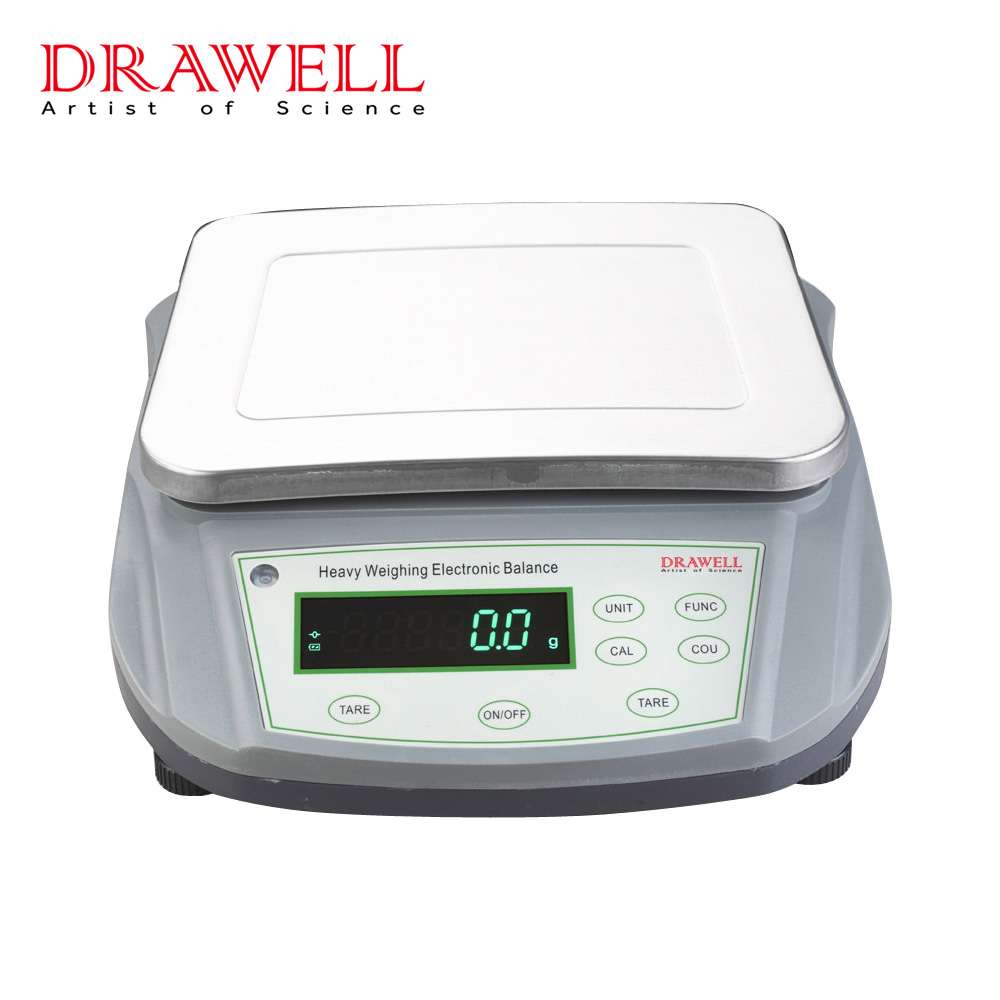

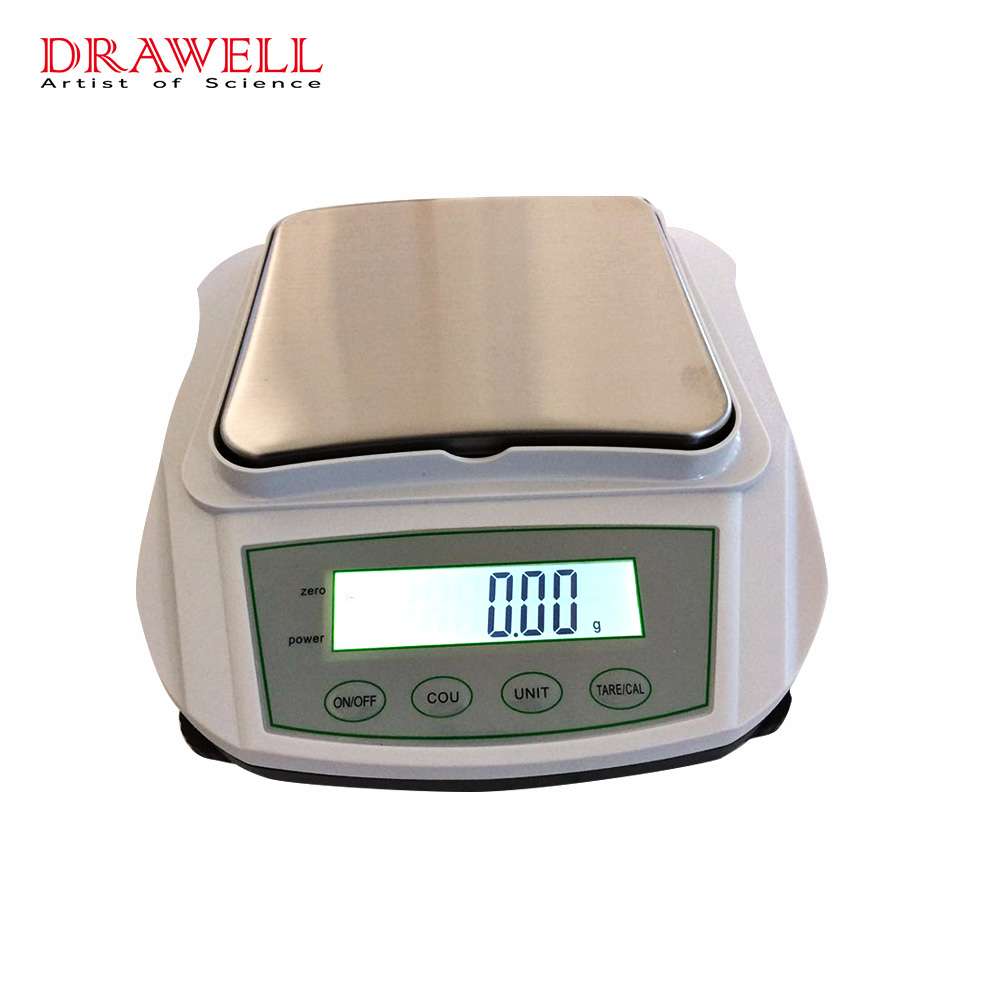

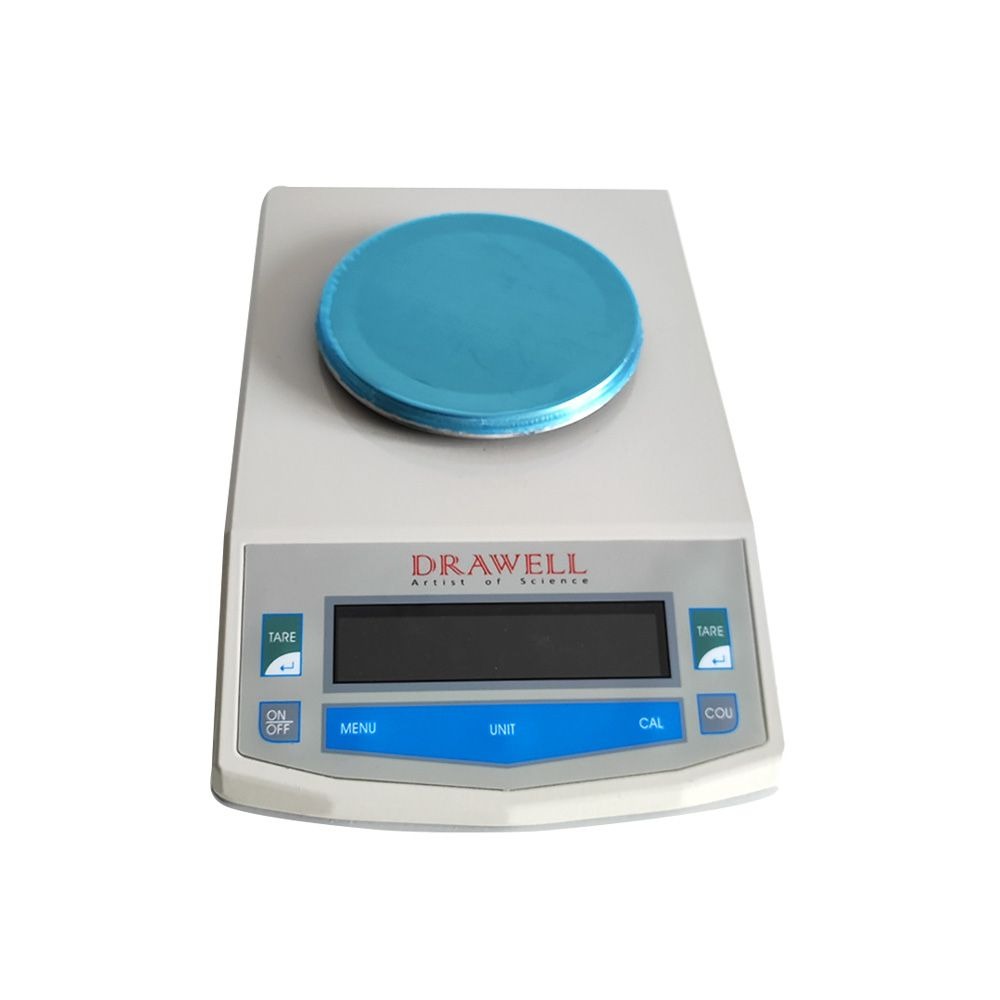

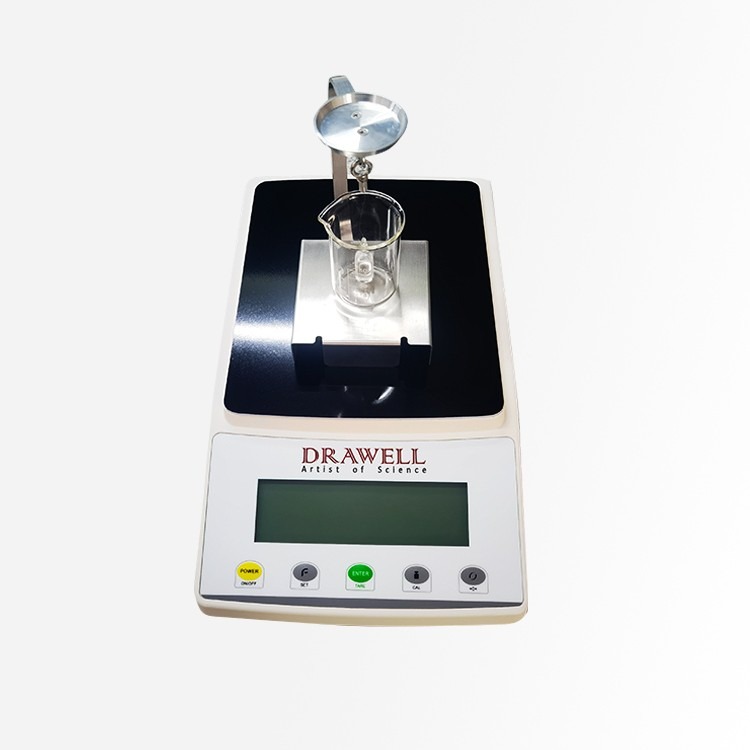

E. Electronic Balances

Electronic balances have revolutionized the weighing process by employing technology to provide fast and accurate measurements. They work based on the principle of electromagnetic force compensation, where the weight of the sample is balanced against an electromagnetic force. These balances offer digital readouts, making data recording and analysis more efficient. However, they require careful handling due to their sensitivity to electrostatic charges.

F. Mechanical Balances

Mechanical balances have a historical significance in analytical work and continue to be used in certain applications. They operate on the lever-arm mechanism, where the sample is balanced against known reference weights. While they lack the digital convenience of electronic balances, they are robust and do not require electricity. Mechanical balances are often used in educational settings to teach the principles of precision weighing.

Factors Influencing Balance Selection

Selecting the right type of analytical balance depends on several factors:

- Required Precision and Sensitivity: The nature of the analysis dictates the level of precision needed.

- Sample Size and Weight Range: Different balances have varying weight capacities.

- Environmental Conditions: Temperature and humidity can affect measurements.

- Budgetary Considerations: Balances range in price, so budget constraints must be considered.

Proper Handling and Maintenance

Regardless of the type of balance, proper handling and maintenance are essential for accurate results:

- Calibration: Regular calibration ensures accuracy and traceability.

- Leveling and Zeroing: Balances should be leveled and zeroed before each measurement.

- Cleaning and Sample Pans: Clean pans prevent contamination that could skew results.

- Preventing Contamination: Handling samples with care prevents cross-contamination.

Safety Considerations

Working with laboratory analytical balances involves safety precautions:

- Toxic or Hazardous Samples: Proper protective equipment is essential when handling toxic substances.

- Electrostatic Discharge: Electronic balances are sensitive to static electricity, so grounding is important.

- Weighing Techniques: Accidents can occur if improper techniques lead to balance overload.

In conclusion, laboratory analytical balances are fundamental tools that underpin the accuracy and reliability of scientific research and industrial processes. From microbalances to analytical balances, each type serves a specific purpose and caters to diverse applications. The choice of balance depends on the precision needed, sample characteristics, and environmental conditions. Proper handling, maintenance, and safety precautions are crucial to ensure accurate results and the longevity of these instruments. As technology continues to evolve, laboratory analytical balances will remain indispensable in various scientific and industrial endeavors.