Advanced control systems in vertical autoclaves represent a significant advancement in sterilization technology, offering precise control, enhanced safety, and improved efficiency. In this article, we delve into the evolution, key components and functionalities, benefits of advanced control systems in vertical autoclaves.

Evolution of Control Systems in Vertical Autoclaves

Traditionally, vertical autoclaves relied on manual controls, requiring operators to monitor and adjust parameters such as temperature, pressure, and cycle duration. While effective, manual control systems were prone to human error and lacked the precision demanded by modern sterilization standards.

The advent of programmable logic controllers (PLCs) revolutionized vertical autoclave control systems. PLCs enabled automated control of sterilization cycles, allowing for precise adjustment of parameters for vertical autoclaves and the creation of customizable cycles tailored to specific sterilization requirements. However, as industries demanded higher efficiency and tighter control over processes, more sophisticated control systems emerged.

Key Components and Functionalities of Advanced Control Systems in Vertical Autoclaves

1. Sensors and Feedback Mechanisms

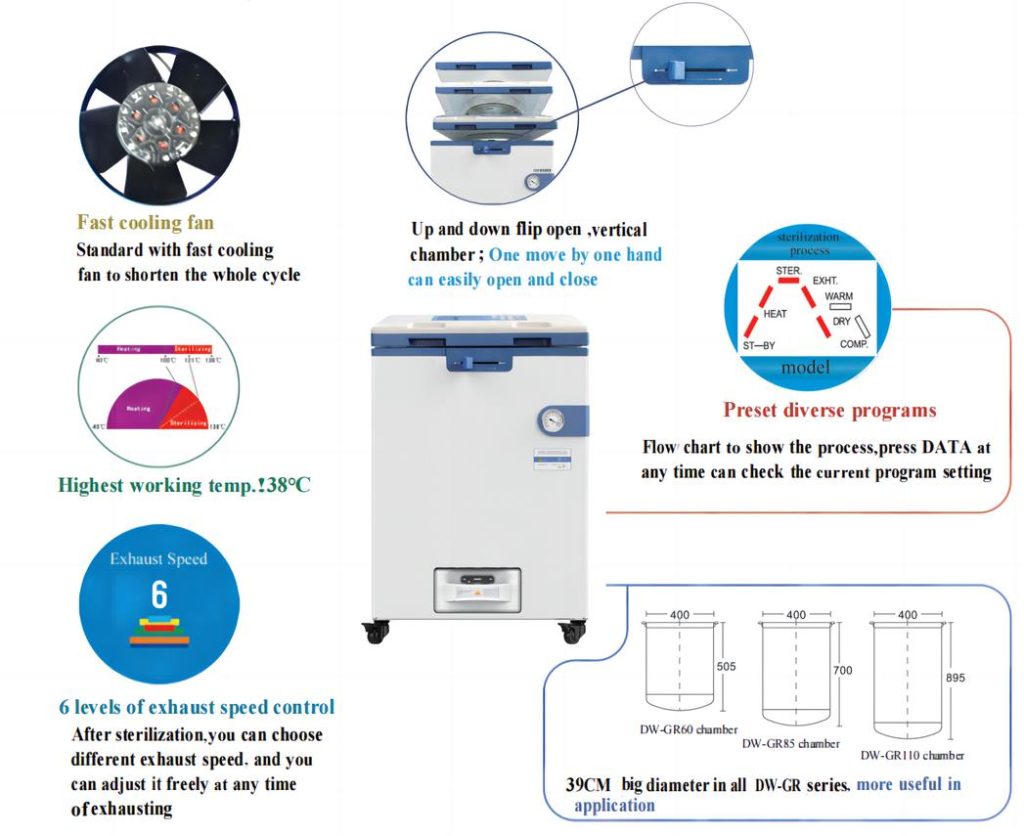

- Advanced control systems incorporate sensors to measure critical parameters such as temperature, pressure, and humidity within the autoclave chamber.

- Feedback mechanisms continuously monitor these parameters and provide real-time data to the control system, enabling precise adjustments during sterilization cycles.

2. Programmable Logic Controllers (PLCs) or Microcontrollers

- PLCs or microcontrollers serve as the brain of the autoclave’s control system, executing programmed commands and regulating the sterilization process.

- These controllers offer flexibility in programming sterilization cycles, allowing for customization based on specific requirements and load types.

3. User-Friendly Interfaces

- Advanced vertical autoclaves feature intuitive user interfaces, often in the form of touchscreen displays.

- These interfaces allow operators to easily input sterilization parameters, monitor cycle progress, and access diagnostic information.

- User-friendly interfaces minimize the potential for operator errors and streamline the operation of the autoclave.

4. Customizable Sterilization Cycles

- Advanced control systems enable the customization of sterilization cycles to suit different materials, load sizes, and sterilization requirements.

- Operators can adjust parameters such as temperature, pressure, cycle duration, and drying times to achieve optimal sterilization results.

- Customizable cycles improve efficiency and ensure the effective sterilization of diverse loads.

5. Data Logging and Traceability

- Advanced autoclave control systems include data logging capabilities to record key parameters throughout sterilization cycles.

- This data can be stored and analyzed for quality control purposes, compliance with regulatory standards, and troubleshooting.

- Data logging facilitates traceability by providing a detailed record of sterilization processes and cycle parameters.

6. Safety Features

- Safety is paramount in autoclave operations, and advanced control systems incorporate various safety features.

- These may include door interlocks to prevent chamber access during pressurized cycles, pressure relief valves to prevent overpressure situations, and emergency stop functions.

- Safety features protect operators, equipment, and the surrounding environment from potential hazards.

7. Remote Monitoring and Control

- Some advanced vertical autoclaves offer remote monitoring and control capabilities.

- Operators can monitor sterilization processes and adjust parameters from a remote location, enhancing flexibility and efficiency in workflow management.

- Remote monitoring ensures that sterilization cycles can be overseen even when personnel are not physically present.

8. Integration with Workflow Systems

- Advanced control systems may be designed to integrate with laboratory information management systems (LIMS) or other workflow management software.

- Integration streamlines data capture, analysis, and reporting, improving overall efficiency and traceability in laboratory operations.

Applications of Vertical Autoclaves with Advanced Control Systems

Vertical autoclaves equipped with advanced control systems find diverse applications across various industries where sterilization is essential.

1. Healthcare Facilities

- Hospitals, clinics, and medical laboratories rely on vertical autoclaves for sterilizing surgical instruments, medical devices, and laboratory equipment.

- Advanced control systems ensure precise sterilization, eliminating pathogens and reducing the risk of healthcare-associated infections (HAIs).

- Customizable sterilization cycles accommodate different types of instruments and materials, optimizing efficiency and efficacy.

2. Pharmaceutical Manufacturing

- Pharmaceutical companies use vertical autoclaves to sterilize vials, ampules, containers, and production equipment.

- Advanced control systems provide regulatory compliance by maintaining accurate records of sterilization parameters and ensuring consistent results.

- Customizable cycles accommodate the specific requirements of pharmaceutical products, maintaining product integrity and safety.

3. Research Laboratories

- Research laboratories in academic institutions, biotechnology firms, and industrial R&D facilities utilize vertical autoclaves for sterilizing laboratory glassware, media, and reagents.

- Advanced control systems offer precise temperature and pressure control, critical for maintaining sterile conditions essential for accurate experimentation and analysis.

- Remote monitoring capabilities enable researchers to monitor sterilization processes from a distance, enhancing workflow efficiency.

4. Food Processing Industry

- Food processing facilities use vertical autoclaves for sterilizing packaging materials, containers, and equipment.

- Advanced control systems ensure compliance with food safety regulations by providing accurate documentation of sterilization processes.

- Customizable cycles accommodate the specific requirements of different food products, preserving quality and extending shelf life.

5. Biotechnology and Life Sciences

- Biotechnology companies and life science laboratories employ vertical autoclaves for sterilizing bioreactors, fermenters, and culture media.

- Advanced control systems offer precise control over sterilization parameters, critical for maintaining sterile conditions in bioprocessing operations.

- Integration with workflow management systems facilitates data capture and analysis, enhancing productivity and traceability.

6. Veterinary Clinics and Research Facilities

- Veterinary clinics, animal research facilities, and diagnostic laboratories utilize vertical autoclaves for sterilizing surgical instruments, cages, and animal bedding.

- Advanced control systems ensure thorough sterilization, reducing the risk of cross-contamination between animals and maintaining a hygienic environment.

- Customizable cycles accommodate the specific sterilization requirements of veterinary equipment and materials.

7. Dental Practices

- Dental clinics and laboratories use vertical autoclaves for sterilizing dental instruments, handpieces, and impression materials.

- Advanced control systems offer quick cycle times and precise temperature control, meeting the demanding sterilization needs of dental practices.

- Safety features such as door interlocks and pressure relief valves protect operators and equipment during sterilization cycles.

Conclusion

Advanced control systems in vertical autoclaves leverage cutting-edge technology to optimize sterilization processes, enhancing safety, and improving user experience. By offering precise control, customization options, and advanced monitoring capabilities, these systems meet the stringent sterilization requirements of diverse industries while ensuring compliance with regulatory standards.