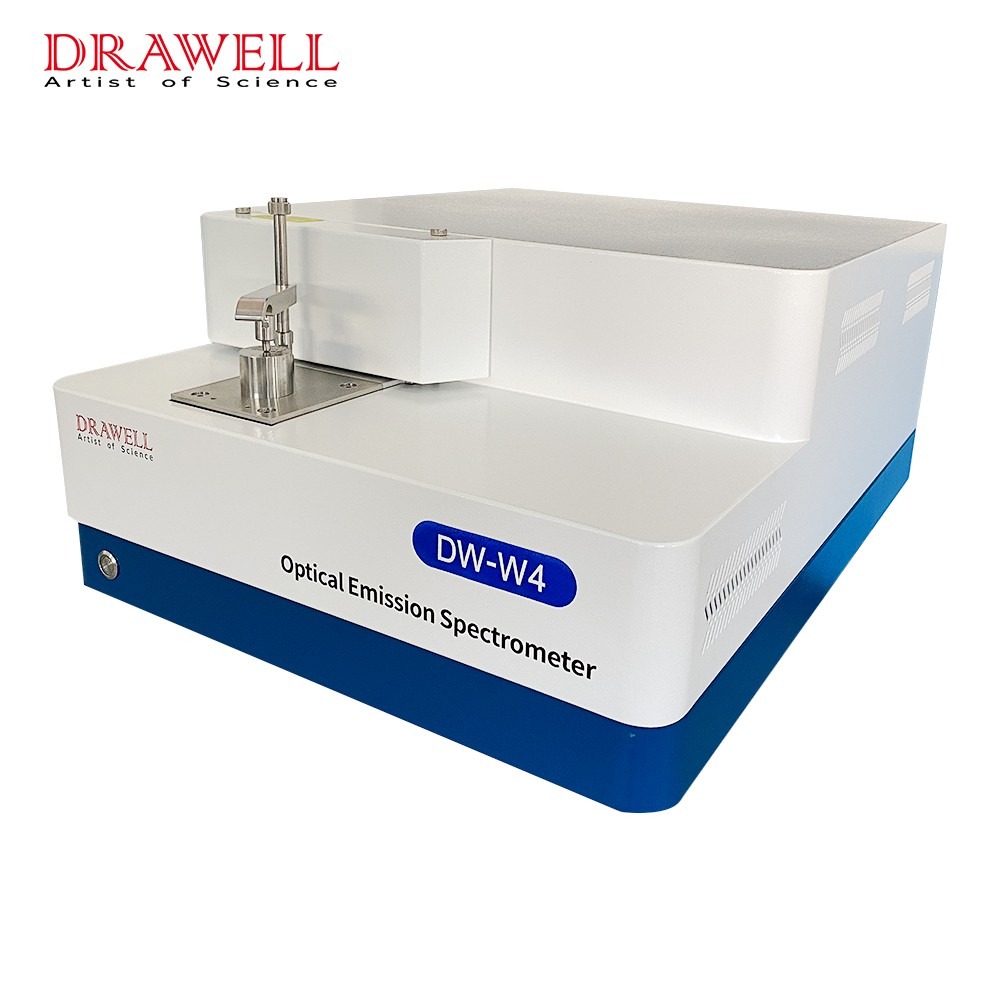

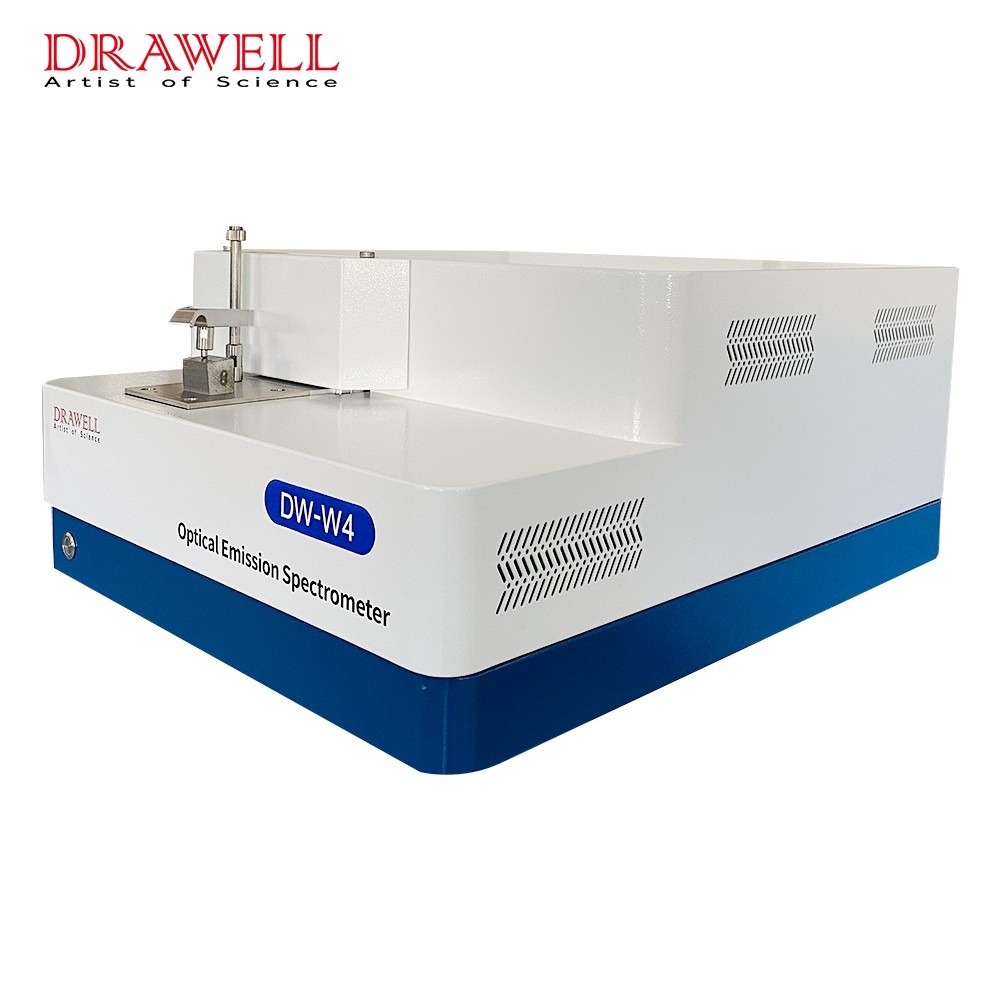

DW-W4 Optical Emission Spectrometers (Arc/Spark-OES) Economical and Easy Metal Analyzer

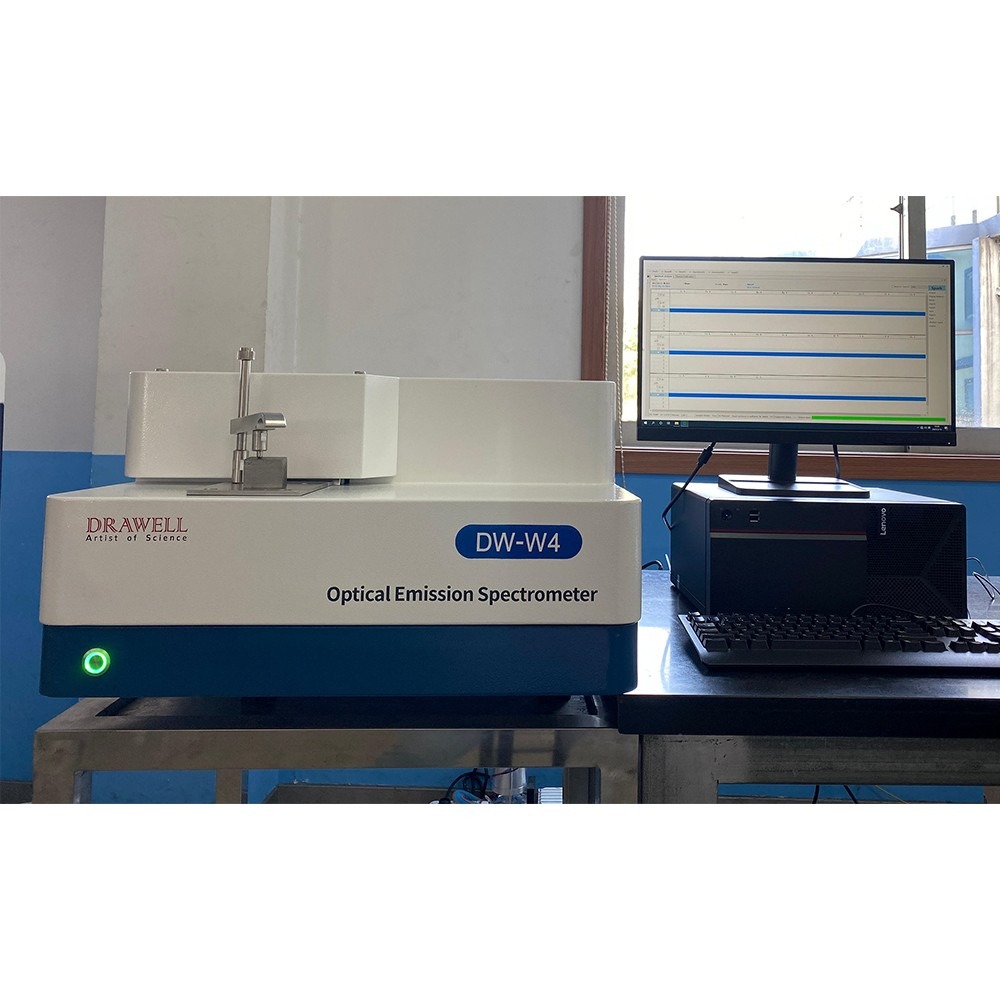

DW-W4 Optical Emission Spectrometer is most suitable instrument for the determination of various elements in different matrices (Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag, etc). It is an economical and easy solution to quick analysis near the furnace, metal material quality analysis, research laboratories and metal grade identification

This also gives the user a truly economical spectrometer that’s both easy to use and easy to space saved. The optical system uses a CMOS detector with a spectral range covering all typical materials. It can accurately and reliably analyze from low-level elements to high-content elements.

Scope of supply

1. Supply list

| No. | Item | Specifications | QTY | Unit | Remarks |

| 1 | Optical Emission Spectrometer | DW-W4 | 1 | Set | Include in quotation. |

| 2 | Business computer | 1 | Set | ||

| 3 | Printer | 1 | Set | ||

| 4 | Tungsten electrode | 1 | Pc | ||

| 5 | Electrode pressure spring | 1 | Pc | ||

| 6 | The electrode fixed screw | 2 | Pcs | ||

| 7 | Electrode brush | Φ6 | 2 | Pcs | |

| 8 | Lens holder sealing ring | Φ16×2.65 | 2 | Pcs | |

| 9 | Lens holder sealing ring | Φ72×2.65 | 1 | Pc | |

| 10 | Exhaust gas filter core | 1 | Pc | ||

| 11 | Degreasing cotton | 15 | G | ||

| 12 | Power socket | 1 | Pc | ||

| 13 | M2 Internal hexagonal wrench | 1 | Set | ||

| 14 | M4 Internal hexagonal wrench | 1 | Set | ||

| 15 | Long handle phillips screwdriver | 1 | Pc | ||

| 16 | 13-15 fixed wrench | 1 | Pc | ||

| 17 | Spark machine screw | M6 | 4 | Pcs | |

| 18 | Fuse | 10A | 2 | Pcs | |

| 19 | Argon gas pressure reducing valve | 1 | Pc | ||

| 20 | Argon gas pipeline | 2 | M | ||

| 21 | Exhaust pipe | 1 | Pc | ||

| 22 | Gas bottle | 2 | Pcs | ||

| 23 | Print paper | 1 | Pc | ||

| 24 | Spectrometer manual | 1 | Set |

Notes: The Buyer knows and agrees that the Seller may adjust the supply when the production of the above-mentioned instruments, spare parts and other suppliers change due to technological progress, product upgrading, market changes, etc.

2. Optical items

| Optional item | Qty | Note |

| High purity argon gas (pure ≧ 99.999%) | 1 bottle | Should prepare by customer. If can’t get should use argon purifier to get 99.999% argon gas. |

| Small air conditioning | 1 set | Essential, customer should prepare by themselves. |

| High precision magnetic saturation voltage stabilizer (1KVA) | 1 set | Need for voltage instability, if the customer uses intermediate frequency furnace, then need 3KVA Voltage Stabilizer |

| Argon purifier | 1 set | When argon gas is not as pure as 99.999%. |

| Samples grinder (ferrous metals) or Mini lathe (non-ferrous metals) | 1 set | Essential |

| Type samples | pieces | Essential for foundry |

Analytical Program

| The analysis ranges and elements of Al base | |||||||

| Al-000 | Al-001 | Al-002 | Al-003 | Al-004 | Al-005 | ||

| No. | Elements | GlobalProgram | Al Low Alloy | Al-Si Alloy | Al-Zn Alloy | Al-Cu Alloy | Al-Mg-Si Alloy |

| 1 | Si | 0.01-24 | 0.01-1.63 | 0.02-24 | 0.02-9.4 | 0.02-7 | 0.02-2.3 |

| 2 | Fe | 0.01-4 | 0.01-1.65 | 0.02-4 | 0.03-1 | 0.05-1.9 | 0.07-0.80 |

| 3 | Cu | 0.002-13 | 0.002-1 | 0.005-6 | 0.01-4.3 | 0.01-13 | 0.07-1 |

| 4 | Mn | 0.001-2.4 | 0.001-1 | 0.005-1 | 0.02-1 | 0.05-1 | 0.03-2.4 |

| 5 | Mg | 0.002-10.2 | 0.002-1 | 0.01-1.5 | 0.01-4 | 0.01-2.7 | 0.006-10.2 |

| 6 | Cr | 0.001-0.5 | 0.001-0.15 | 0.005-0.5 | 0.01-0.4 | 0.01-0.14 | 0.01-0.4 |

| 7 | Ni | 0.001-2.5 | 0.001-0.16 | 0.02-2.5 | 0.01-0.2 | 0.01-2.3 | 0.005-0.25 |

| 8 | Zn | 0.002-12 | 0.002-0.5 | 0.005-3.5 | 0.01-12 | 0.05-3.5 | 0.01-1 |

| 9 | Ti | 0.001-0.4 | 0.001-0.15 | 0.005-0.4 | 0.005-0.3 | 0.001-0.2 | 0.007-0.3 |

| 10 | Cd | 0.001-0.3 | 0.01-0.3 | 0.001-0.3 | 0.002-0.3 | 0.01-0.3 | 0.01-0.3 |

| 11 | Pb | 0.001-0.5 | 0.02-0.5 | 0.005-0.5 | 0.005-0.5 | 0.01-0.5 | 0.001-0.5 |

| 12 | Sb | 0.005-0.4 | 0.005-0.4 | ||||

| 13 | Sn | 0.005-0.5 | 0.01-0.2 | 0.003-0.5 | 0.005-0.2 | 0.02-0.3 | 0.007-0.2 |

| 14 | Sr | 0.005-0.1 | 0.005-0.1 | ||||

| 15 | V | 0.002-0.2 | 0.004-0.05 | 0.005-0.2 | 0.005-0.03 | 0.01-0.03 | 0.002-0.03 |

| 16 | Zr | 0.001-0.3 | 0.001-0.12 | 0.005-0.2 | 0.01-0.3 | 0.001-0.2 | 0.003-0.12 |

| 17 | p | 0.002-0.005 | 0.002-0.005 | ||||

| 18 | Al | Reference | Reference | Reference | Reference | Reference | Reference |

| No. | Elements | Brass |

| 1 | Zn | 0.5-43.0 |

| 2 | Pb | 0.01-6.0 |

| 3 | Sn | 0.009-4.8 |

| 4 | P | 0.002-0.14 |

| 5 | Mn | 0.001-5.3 |

| 6 | Fe | 0.02-3.0 |

| 7 | Ni | 0.009-1.8 |

| 8 | Si | 0.001-4.6 |

| 9 | Mg | 0.001-0.01 |

| 10 | Cr | 0.001-0.2 |

| 11 | Co | 0.004-0.1 |

| 12 | Al | 0.001-6.7 |

| 13 | S | 0.001-0.15 |

| 14 | Cu | Reference |

Note:

The instrument is calibrated with limited standard samples which Chongqing Drawell Instrument Co., Ltd. have for general purpose. For special alloy and special elements, the instrument must be calibrated by customer themselves. Or if customer is willing to provide sample collaboration for program development, the customer must provide accurate sample element content tables and ensure sample uniformity, but such curves are not used as acceptance indicators of the instrument.

Technical Data of DW-W4

1. Parameter

| Item | Index | |

| Optical System | Focal Length | 350mm |

| Wavelength range | 165nm-589nm(extendable) | |

| Detector | High resolution CMOS Multi detectors | |

| Light chamber | Argon cycle filling | |

| Pixel resolution | 30pm | |

| Grating line | 3600m1/mm | |

| First order spectral line dispersion rare | 1.2nm/mm | |

| Average resolution ratio | 10pm/pixel | |

| Full spectrum | ||

| Light chamber temperature is controlled automatically | ||

| Spark Source | Type | Digital arc and spark source |

| Spark frequency | 100-1000HZ | |

| Discharge current | 1-400A | |

| Ignition voltage | >15000V | |

| Excitation light | Optimization of discharge parameters design | |

| High energy precombustion technology HEPS | ||

| Processor | High-speed data synchronization acquisition and processing | |

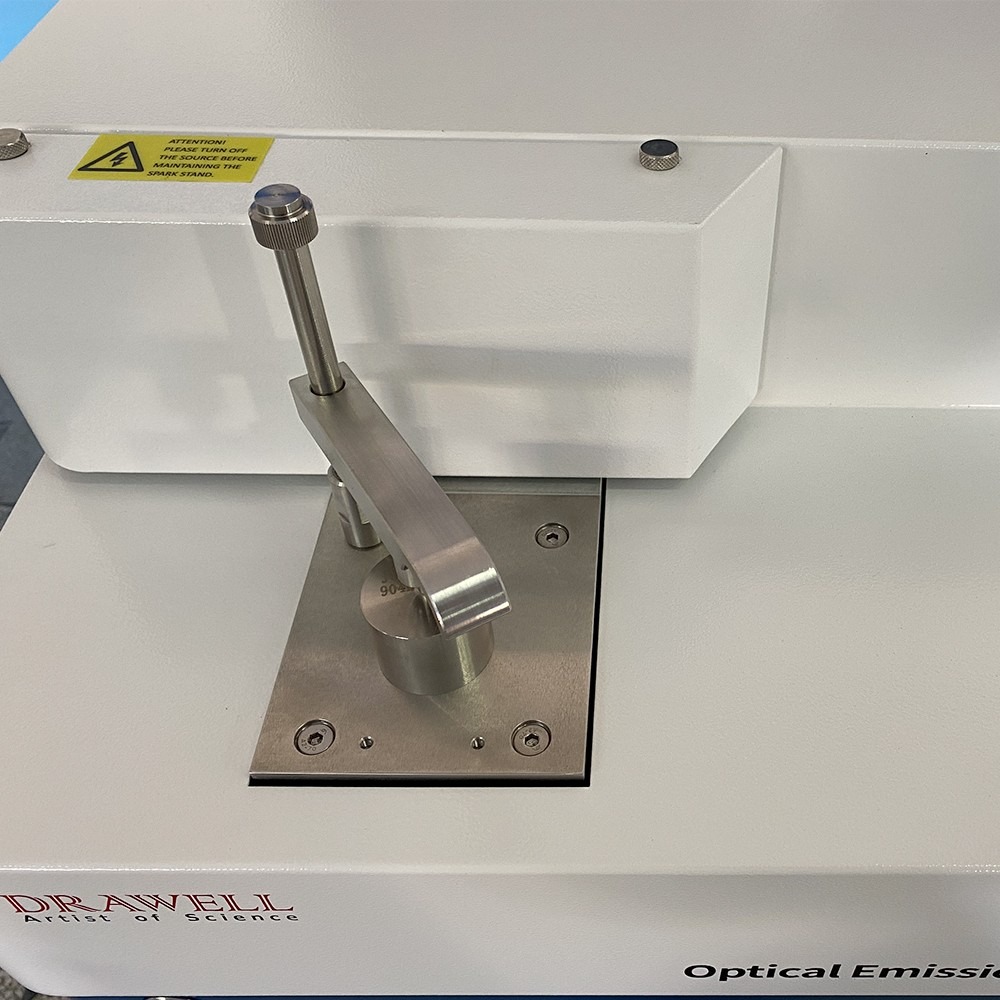

| Spark Stand | Electrode | Tungsten electrode technology |

| Make up | Thermal deformation self-compensation design | |

| Argon flushed with minimal consumption of Argon | ||

| Spray discharge electrode technology | ||

| Adjustable electrode technology | ||

| Others | Measurable elements | Fe、Al、Cu、Ni、Ti、Co、Zn、Sn、Mg、Pb etc |

| Dimension | 714mm(L)*558mm*270mm(H) | |

| weight | About 40kg | |

| Storage temperature | 0℃-45℃ | |

| Operating temperature | 10℃-35℃, 23±2℃ is recommended | |

| Power | AC220V/50Hz(Customized) | |

| Power consumption | Excitation:400W/Stand by:50W | |

| Argon quality | 99.999%, Argon pressure>4Mpa | |

| Argon consumption | 5L/min during spark mode | |

| Interface | Ethernet data transmission based on DM9000A | |

2. Main features

The DW-W4 optical emission spectrometer has a number of patented technologies that enable rapid determination of elements in metallic materials. The optical system uses a CMOS detector with a spectral range covering all typical materials. It is accurate and reliable for analysis from low-level elements to high-level elements. For different materials and different requirements, the cost-effective full-spectrum direct reading spectrometer can meet the requirements of metal manufacturing, processing industry and metal smelting for quality monitoring, material identification, material research and development.

1. Optical system with superior performance

- The Paschen-Longge structure concave grating, full spectrum coverage, meets the customer’s need for full element detection.

- Direct optical technology and use optics made with MgF materials ensure optimum performance in the UV region.

- High resolution multi-CMOS readout system, lower dark current, better detection limit, higher stability, stronger sensitivity, meet N analysis requirements.

2. Large energy digital spark light source

- Fully digital intelligent composite light source DDD technology brings superior analytical performance.

- The compact design and semiconductor control technology make the light source more stable and more reliable.

- High-energy pre-combustion technology(HEPS), spark parameter adjustment, fully meet the excitation requirements of different substrates, different samples and different analytical elements.

3. Humanized sample spark stand design

- The spark stand directly introduces the spark light into the optical system

- Open sample stage for large sample testing requirements.

- Change electrodes provide better performance for small sample and complex geometry samples

4. Simple argon flow design

- Intelligent argon flow design and dust collection and cleaning device

- The unique argon jet technology effectively eliminates the drift of the plasma during the spark process, ensuring that the CCD detector can observe the high-temperature regional light signal, improving accuracy and stability.

- After sparking, pulsed argon purge improves dust removal and improves instrument short-term and long-term stability.

5. Fully intelligent vacuum measurement and control

- The vacuum system is fully programmed to reduce the running time of vacuum pump while ensuring the vacuum.

- The two-stage setting turns on the standby vacuum operation state when the instrument is not running.

- Multi-stage vacuum isolation measures and the addition of oil filter devices ensure that optical components work in a reliable environment.

6. Convenient and quick lens cleaning device

- The integrated vacuum ball valve has good isolation when cleaning the lens.

- Single-plate lens design, easy to assemble and disassemble.

- Cross-mechanical devices, the optical system is effectively protected without isolation.

7. Cloud computing and reading system

- The computer and mobile phone (or PAD) can be displayed simultaneously for easy panel operation.

- High resolution multi-CMOS readout system and FPGA, DSP and ARM technology for data acquisition.

- Ethernet and TCP/IP protocols, data transmission is fast and reliable.

- Data can be transmitted remotely and fully networked. Real-time monitoring and control of the operating state of the instrument.

- Data can be cloud printed.

8. Dedicated spectral analysis software

- The international spectrometer produces a standard dedicated spectrometer software with user-friendly interface and standardized functions.

- The instrument is equipped with multiple factory calibration curves and more material analysis methods and advanced solutions in the software.

- The upper and lower limits of the standard curve can be extended on site according to the material requirements of the user.

9. The instrument and software computing power is powerful

- Automatic optical path calibration

- Low argon consumption

- Universal adjustable sample adapter

- Base extension

- Standardized parameter modification

- Type standardization function

- Safer, more open and convenient design

- The result is displayed in real time, and the print report function can be customized for the user.

- Software rapid diagnosis

- Simple interface operation

- Reliable factory calibration