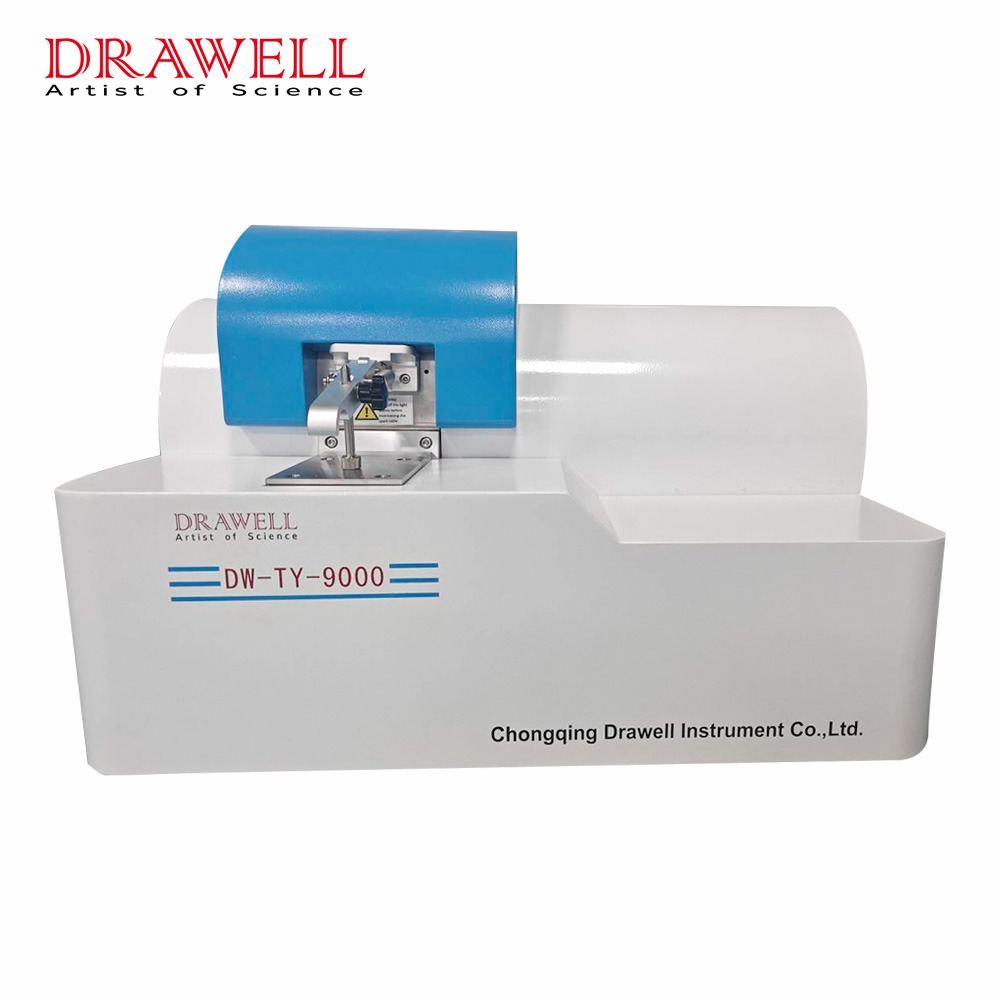

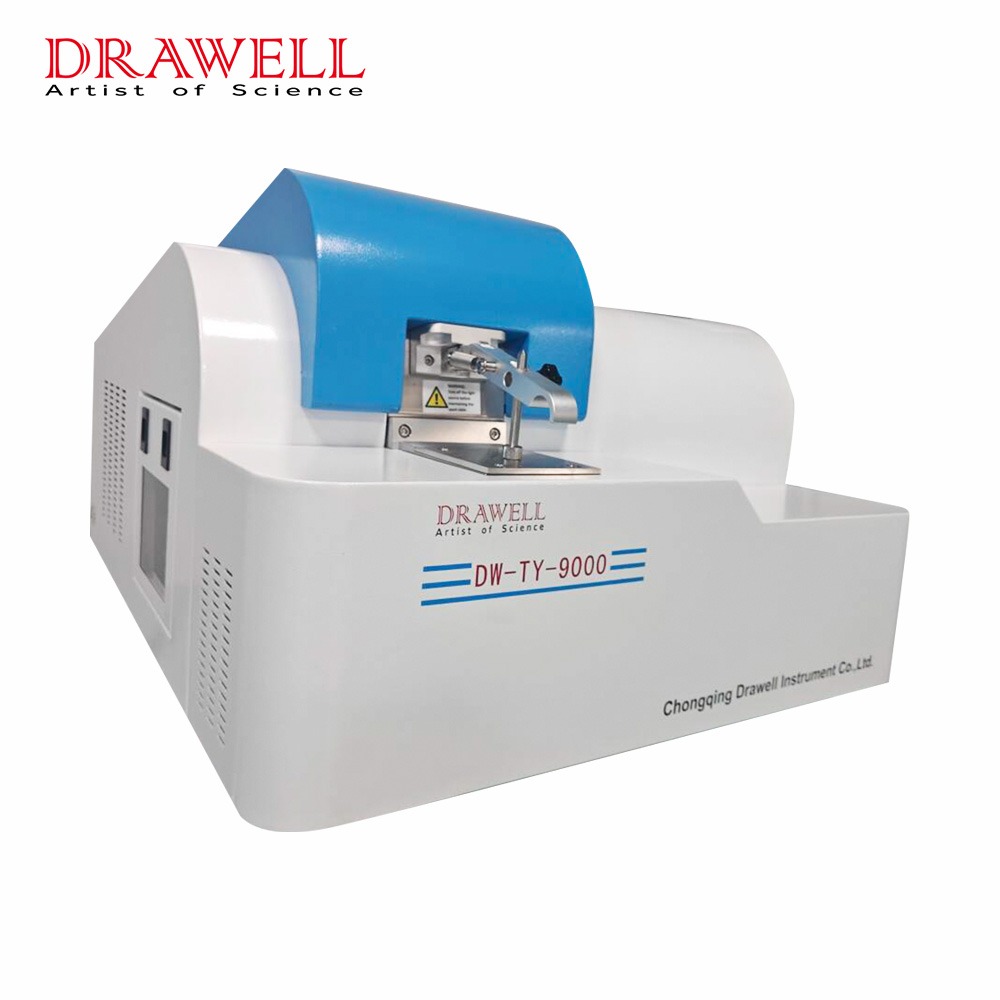

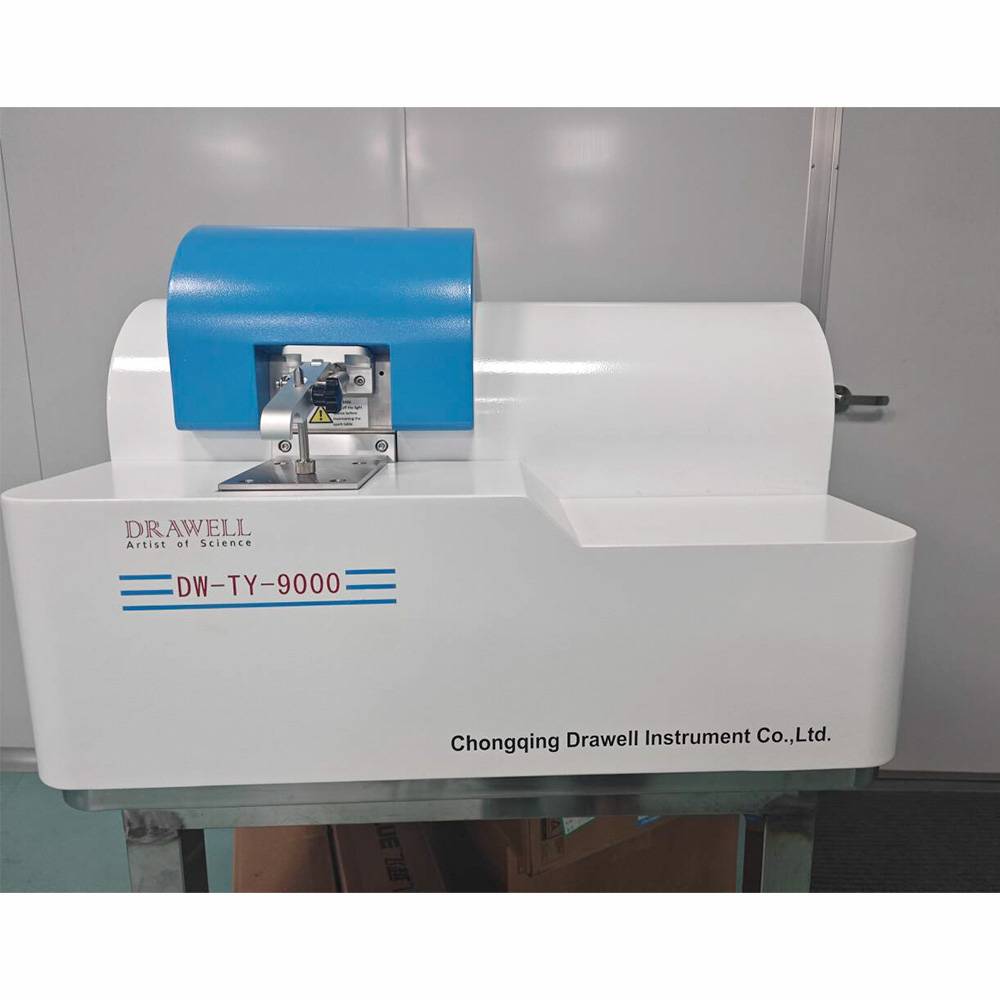

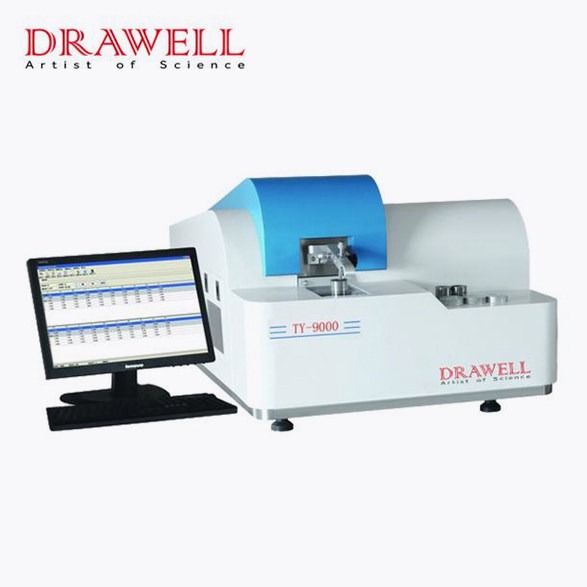

DW-TY-9000 Full Spectrum Direct Reading Spectrometer

DW-TY-9000 is a Full Range of Solutions for the Entire Metals Industry. It uses full-digital technology to replace bulky photomultiplier tube (PMT) simulation technology and keep pace with international spectrometer technology. The adoption of a vacuum optical chamber design, full-digital excitation light source, advanced CCD detectors, and high-speed data readout system equips the device with high properties, ultra-low limit of detection (LOD), long-term stability, and repeatability. The analytical precision can meet the requirements of laboratory standards, the analytical data is stable and reliable. Widely used in metallurgy, casting, machinery processing, and other industries incoming and outgoing product quality control.

Technical Configuration of Full Spectrum Direct Reading Spectrometer DW-TY-9000

1. Specifications and Technical Parameters

| Item | Index |

| Detection of substrate | Fe、Al、Cu、Ni、Ti、Co、Zn、Sn、Mg、Pb etc |

| Testing time | According to the sample type, generally about 25s |

| Optical system | The Paschen Runge construction full vaccum type optics system |

| Wavelength coverage | 130~800nm |

| Focal length | 400mm |

| Detector | High-performance CCD Array |

| Electrode | Tungsten material injection electrode |

| Analytical gap | The sample analysis of clearance: 3.4mm |

| Operating temperature | (10~35)℃ |

| Storage temperature | (0~45)℃ |

| Operating humidity | 20%~80% |

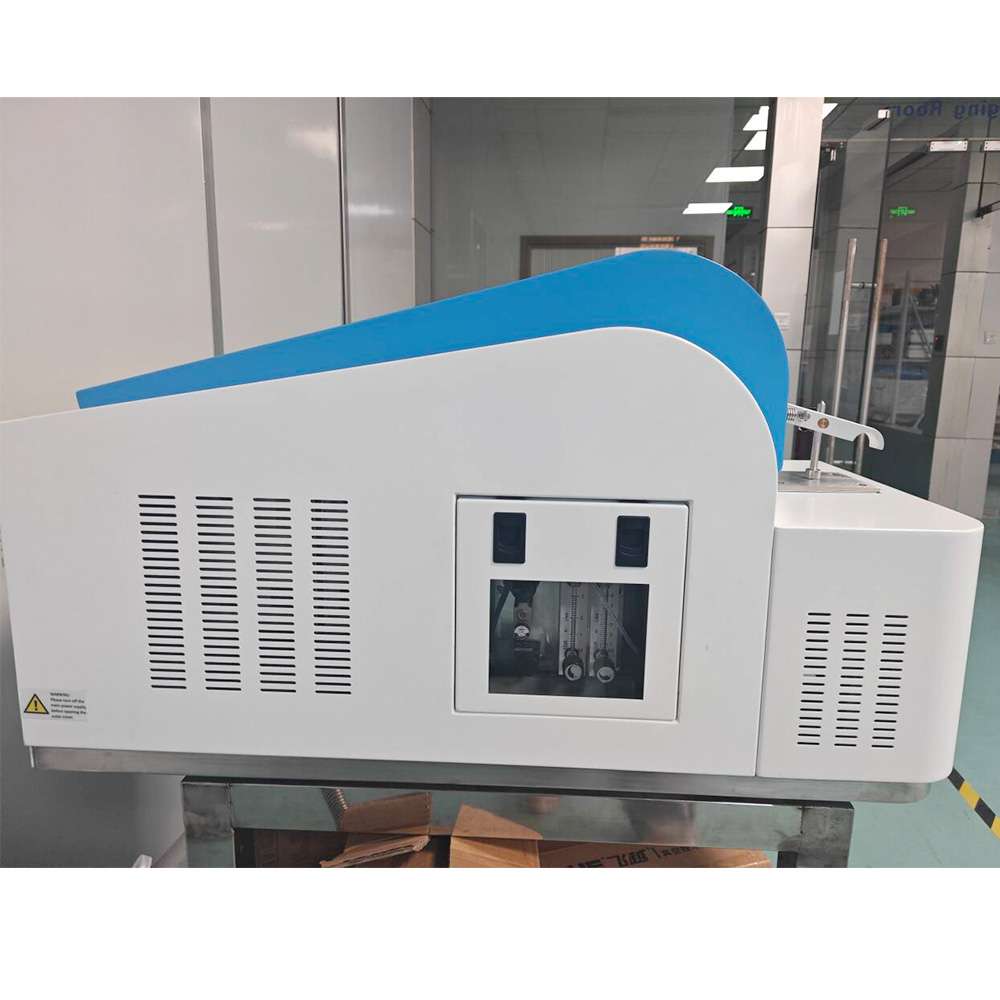

| Argon purity requirements | 99.999% |

| Argon gas inlet pressure | 0.5MPa |

| Argon flow | Stimulate the flow around 3.5L/min,Maintain flow around 0.4L/min |

| Stimulate the maximum power | 400VA |

| Type of Lamp-house | New digital adjustable light, high energy precombustion technology(HEPS) |

| Discharge frequency | 100-1000 Hz |

| Discharge current | Maximum 400A |

| Excitation aperture | 13mm |

| Vacuum system | The vacuum automatic control and monitoring software |

| Working power supply | 220V AC, 50/60Hz, single phase power supply for protective grounding |

| Instrument size | 725*865*550(mm) |

| Instrument weight | 80kg |

2. Optical System

- Par type Paschen-Runge structure full spectrum of the optical system;

- Maximum wavelength range(160~850)nm;

- Multiple high-performance CCD detectors;

- Integration of optical chamber forming, dynamic Romanian archives park installation, resistance to environmental temperature changes;

- Light vacuum chamber designed to ensure the C, S, P, N to achieve the best performance;

- Ray room temperature control, constant temperature of 35℃;

- Direct MgF2 lens optics technology and materials to ensure the best energy C, S, P, N ultraviolet wavelengths.

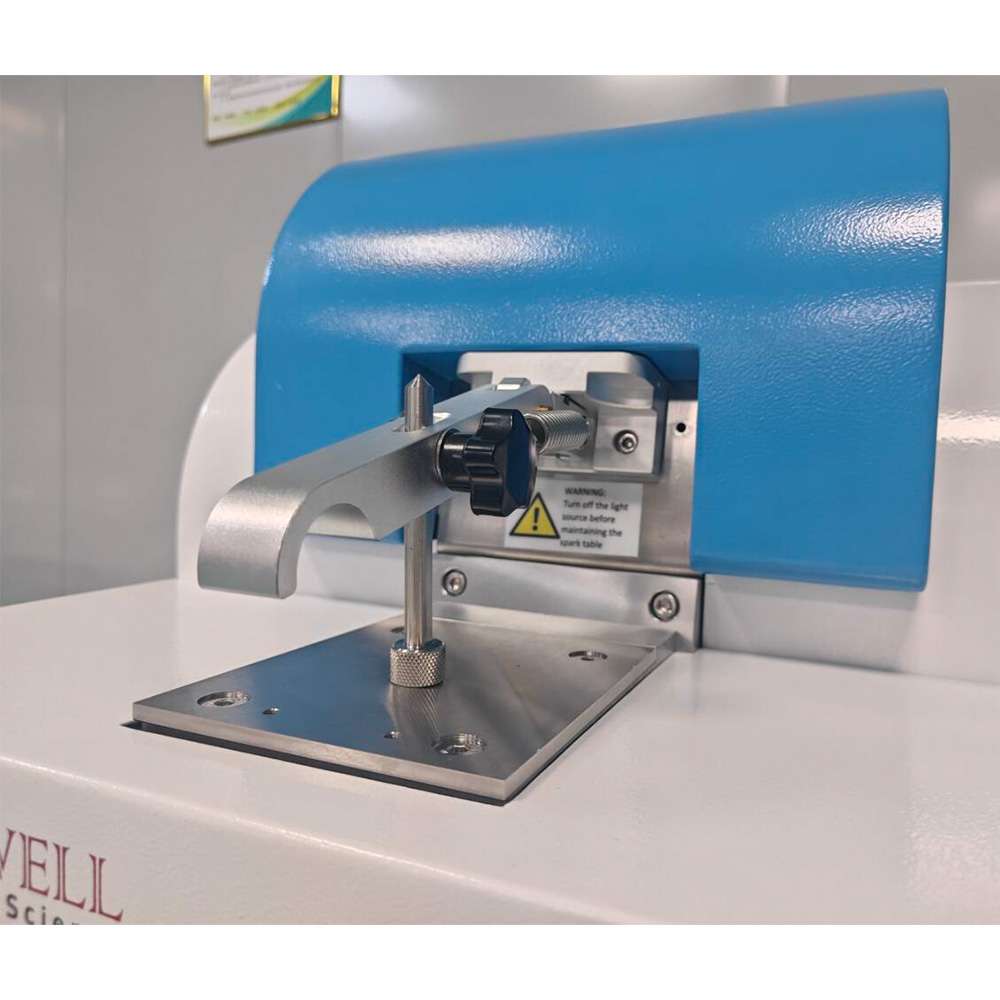

3. Sample Excitation Station

- Integrated manifold, injection electrode technology;

- Optimization of argon gas circuit design ensures effective cooling station excite and motivate metal dust generated in the process effectively into the filter; the sample excitation is more stable, and greatly reduce the body’s intake of metal dust, help protect the operator health and safety;

- Smaller excitation space, argon gas consumption less;

- Easy to use sample holder;

- With the function of the electrode electrode should sweep, longer service life, easy cleaning electrode;

- 13 mm aperture stimulate a more conducive sample analysis;

- Open sample excitation table can be adapted to a variety of sizes, shapes analyze more samples (with cable);

- SLR Lens device design, the general staff can facilitate the maintenance of the excitation and lens cleaning.

4. Excitation Light Source

- New adjustable digital light source, the highest frequency up to 1000Hz;

- High energy prediction technology (HEPS);

- Optimized design of the control and power circuits, improve security features excite;

- Provide the best analysis for different target spark, an arc or a combination of excitation waveforms;

- Discharge current: 400 A Max.

5. Data Acquisition System

- High performance ARM data processor, with ultra high-speed data acquisition and control functions

- High performance CCD solid-state detection technology, spectrum bands within the full spectrum reception;

- External computer (optional);

- FPGA and high-speed data communication technology, data is read into a powerful, test data is read as a whole a short time.

6. Analysis Software

- CCD-based multi-language Windows system full spectrum graphical analysis software, convenient and practical;

- Comprehensive management control of the entire measurement process and provide users with powerful data processing capability and test report output capacity;

- Instrument can be configured with multiple factory calibration curve and more material analysis and advanced solutions;

- Software to achieve full spectrum of detection, intelligent deduction interference, buckle dark current, background and noise algorithms to improve analytical instruments;

- Complete automatic system diagnostics;

- Comprehensive database management functions can be easily query, summary data;

- Intelligent correction algorithms to ensure stable and reliable instrument;

- Complete spectrum of information and interference deduction algorithm to ensure more accurate instrumental analysis;

- Adapt to the latest Windows operating systems.

Elements and The Scope of Instrumental Analysis

| Program | Fe-Low alloy | Fe-Cr-Ni steel Cr-Ni | ||

| Elements | Min | Max | Min | Max |

| C | 0.006 | 1.3 | 0.008 | 2.5 |

| Si | 0.01 | 3.9 | 0.09 | 4 |

| Mn | 0.03 | 2.1 | 0.12 | 16 |

| P | 0.002 | 0.12 | 0.003 | 0.3 |

| S | 0.002 | 0.16 | 0.001 | 0.4 |

| Cr | 0.01 | 4.5 | 7.4 | 32 |

| Ni | 0.004 | 4.4 | 0.8 | 48 |

| Mo | 0.004 | 1.3 | 0.08 | 4.2 |

| Al | 0.003 | 1.5 | 0.005 | 1.7 |

| Cu | 0.002 | 0.5 | 0.05 | 4.5 |

| Co | 0.001 | 0.5 | 0.008 | 17 |

| Ti | 0.002 | 1.2 | 0.005 | 1.1 |

| Nb | 0.002 | 0.3 | 0.02 | 2 |

| V | 0.003 | 0.9 | 0.02 | 9.5 |

| W | 0.03 | 2.1 | 0.002 | 4.1 |

| Pb | 0.003 | 0.03 | 0.001 | 0.02 |

| Mg | 0.001 | 0.14 | 0.001 | 0.14 |

| B | 0.006 | 0.02 | 0.007 | 0.02 |

| Sn | 0.001 | 0.09 | 0.003 | 0.05 |

| Zn | 0.002 | 0.04 | 0.006 | 0.08 |

| Sb | 0.002 | 0.02 | 0.0005 | 0.022 |

| Fe | (Remain) | (Remain) | ||

Notes:

(1) The table filled in accordance with contract demand of customers;

(2) If the customer has control sample needs to provide control sample number, by the customer to buy their own; for example, sales staff and buy, the control sample Shanghai shipped separately;

(3) If the client application is a special application, and are willing to cooperate to provide samples for curve development, the customer must provide accurate sample elements in the table, and to ensure uniformity of the sample, but not as an instrument of this type of curve acceptance criteria;

Installation and Commissioning of Full Spectrum Direct Reading Spectrometer DW-TY-9000

1. Delivery check and storage

After the buyer receives the goods, you should check the packaging is intact. As packaging is damaged or corrupted direct reading spectrometer, the user should keep relevant evidence and promptly notify the seller, with the seller to the responsible party claim. Otherwise, assume self-destruction of the goods by the buyer.

After the equipment arrived at the buyer, the buyer should be placed in the instrument temperature 0℃ ~ 45℃, humidity 20% to 80% of the indoor environment in custody. Before installing the engineer does not arrive, the buyer can not be allowed out of the box, otherwise regarded as acceptance of goods.

2. Installation and Commissioning

Instruments arrive within a month, the buyer should have the installation conditions and notify the seller installed.

After installation engineers arrived, along with the packing list one by one to check received by both parties, representatives of both parties to fill the packing list in duplicate entries in acceptance based on test results and signed. If missing parts on the acceptance of a single note by the installation engineer and immediately notify the seller sent it to us.

Instruments arrive within two months the buyer still have installation conditions, or cause damage to the instrument in custody, the seller is entitled to require the buyer to pay the additional installation costs, all costs for equipment damage caused by the formation of custody shall be borne by the buyer.

In instrument installation and commissioning, the buyer should be given to facilitate the installation engineer working conditions. Because if the buyer does not have the installation conditions resulting installation engineers to the scene after the unable to work and staying two days (or more), installation engineers can directly return, and to assume the installation engineer during detention by the buyer of the full cost, including transportation to and installation engineers fees, room and board, fees and subsidies.

If the content is not individual elements within a selected range of standard content, or after installation of its RSD, SD value exceeds the allowable value, the two sides should negotiate, analyze problems and propose solutions to problems.

After acceptance, representatives of both parties sign it in duplicate on the acceptance of a single installation.

Note: For customers with samples to create a curve as a standard case, because the customer can not guarantee uniformity of standards, samples of impurities can not be completely sure, the sample providers do not have the qualifications national standard production, so the results of the analysis can not be used as acceptance criteria .

Installation steps:

1) Engineer to the site according to the instrument installation procedures for installation, commissioning.

2) Test sample selection:

According to the buyer’s analysis of the content of the sample, the seller and the buyer to jointly negotiate to determine, select a set of suitable for the user’s daily analysis of the standard sample (the set of the buyer to provide or negotiate with the seller purchasing), as the instrument of acceptance. The standard sample selection principle should be based on the principle of the content of the daily production of the buyer.

3) Test:

After the instrument, the instrument temperature, pressure and argon atmosphere after the instrument to meet the requirements of the instrument, by the seller and the installation engineer with a set of pre – determined, the establishment of the instrument, and then the two sides agreed to take a sample of the standard sample (usually not containing high and low standard sample) for precision testing. General provision of 4~6 points (excluding abnormal excitation) of data to calculate.

After acceptance, the installation of the negotiators in duplicate sign acceptance certificate.

Note: for customers to provide samples as the standard sample to establish the curve, because the customer standard sample uniformity can not guarantee, the sample impurities content can not be completely determined, the sample provider does not have the national standard material production qualification, so the analysis results can not be used as the aaceptance index.