DW-EXPEC3200-115 Portable Methane and Non-Methane Total Hydrocarbon Analyzer

The analyzer uses high temperature sample transfer and high temperature FID detection technology (up to 180℃), mitigating the loss of high boiling point and high concentration samples.

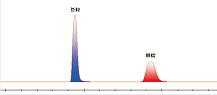

The sample gas is filtered through a secondary filter and enters the quantification ring for accurate quantification, after which the sample is separated by the chromatograph into a hydrogen flame ionization (FID) detector.

The FID detector is capable of accurately measuring total hydrocarbons, methane, non-methane total hydrocarbons and other characteristic factors in stationary and unorganized emissions with detection limits up to the ppb level.

The DW-EXPEC3200-115 Portable Methane and Non-Methane Total Hydrocarbon Analyzer is fully compliant with the HJ1012-2018 Technical Requirements and Test Methods for Portable Total Hydrocarbon, Methane and Non-methane Total Hydrocarbon Monitors for Ambient Air and Exhaust Gases. The technical principles of the product are in accordance with the HJ38-2107 Measurement Point Gas Chromatography for Total Hydrocarbons, Methane and Non-methane Total Hydrocarbons in Waste Gas from Stationary Pollution Sources.

Features of DW-EXPEC3200-115 Portable Methane and Non-Methane Total Hydrocarbon Analyzer

- Highly integrated

By integrating a conventional online methane and non-methane total hydrocarbons monitoring system into one portable instrument, including a display module, chromatography analysis module, FID, battery, hydrogen cylinder, zero cylinder and calibration cylinder, it frees customers from the need to search for various calibration gases, piping and electrical connections so that they can focus more on the detection, with no external cylinder accessory box, battery accessory box or external connections required.

- No commercial power required; long battery life for added safety

The battery has a large capacity of approximately 19.2Ah, which can power both the tracer line and the main unit of the instrument, so as to run and measure non-GMH results without any external power supply or commercial power on site.

- Measurement accuracy

High-temperature heat tracing in the whole process: from the sampling to the FID, a high temperature heat tracing above 120°C (up to 180°C) is adopted in the whole process, which solves the problem of sample loss in the high temperature and high humidity gas environment, and provides accurate test results.

The Chinese-version software allows all maintenance and diagnostic operations, as well as setting the instrument’s operating parameters and performing automatic data processing. The instrument can be connected to an external tablet PC in real time via WIFI for wireless control and spectral analysis

Quality assurance: multiple calibration curves can be set up and calibrated on site without external calibration gas.

- It allows testing institutions to expand the items and produce the original spectrum

Main unit spectrogram display: The host of the analyzer uses a large color touch screen to display test concentrations and spectra (with national CPA certification), and supports the export of original test data and original test spectra for third-party testing agencies to issue CMA reports with original spectra.

- Easy to operate and a wide range vof accessories

The instrument can be equipped with a tablet PC, mobile phone, high-pressure and hydrogen storage cylinders, and analytical instruments that can be connected to a mobile handheld terminal via WIFI and controlled from the handheld terminal. The instrument is fully automatic pressure controlled and adopts a fully automatic electronic pressure control (EPC) module for the gas paths of the carrier gas, hydrogen and combustion gases, with a pressure control accuracy of better than ±0.1kPa.

- High safety

The detector is a miniaturized, dedicated hydrogen flame ionization (FID) detector with automatic electronic pressure control, automatic ignition and automatic adjustment of the ignition airflow. It also provides real-time flame temperature measurement and flame failure protection. Flame temperature can be sensed when flame failure occurs. If any flame failure is detected, automatic/manual ignition will be triggered to restore the normal operation.

Applications of DW-EXPEC3200-115 Portable Methane and Non-Methane Total Hydrocarbon Analyzer

- Environmental audits and enforcement of fixed pollution sources and plant boundaries

- Testing of non-methane total hydrocarbons by third-party testing companies

- Assessment of the effectiveness of VOC pollution control facilities

- Self-inspection of VOC emissions from chemical, printing, dyeing and painting enterprises

- On-site testing and regulation of kitchen fumes

- On-site comparison and acceptance of automatic VOC monitoring systems

- VOC emission testing of combustion unit exhaust gas.

Specifications of DW-EXPEC3200-115 Portable Methane and Non-Methane Total Hydrocarbon Analyzer

| Item | Technical parameters |

| Physical dimensions and weight | Dimensions: 413 x 251 x 348 mm; main unit approx. 10 kg, can be easily carried by hand |

| Power requirements | Battery powered (24 V, 19.2 Ah) or adapter powered (220 VAC, 50Hz) |

| Working temperature | (-15-45) °C |

| Working humidity | (0~95)%RH |

| Detector | Heating miniaturized dedicated flame ionization detector (FID) |

| Limit of detection of FID | ≤0.1 ppm |

| Repeatability | Qualitative repeatability: ≤0.5%; Qualitative weight repeatability ≤2.0% |

| Measurement range | 0-30000 mg/m3 |

| Analysis cycle | ≤2min (non-methane total hydrocarbons) |

| Sampling probe temperature | (0-180)°C |

| Maximum humidity | (0-200) °C |

| Sample gas flow rate | ≥0.6L/min |

| Carrier gas | 75 mL built-in high-pressure cylinder supply, high purity nitrogen, refillable |

| Hydrogen | 75 mL built-in high-pressure cylinder supply, refillable, with optional hydrogen storage alloy |

| Standard gas | 75 mL built-in high-pressure cylinder supply, from specialist gas supplier, refillable |

| High pressure cylinder | Cylinder pressure over 2000 psi; operation time at 2000 psi ≥3 h; filling time <5 s |

| Battery life | Charging time <8h; operation time after full charge ≥4h (main unit + heating line), or ≥7h (separate main unit) |