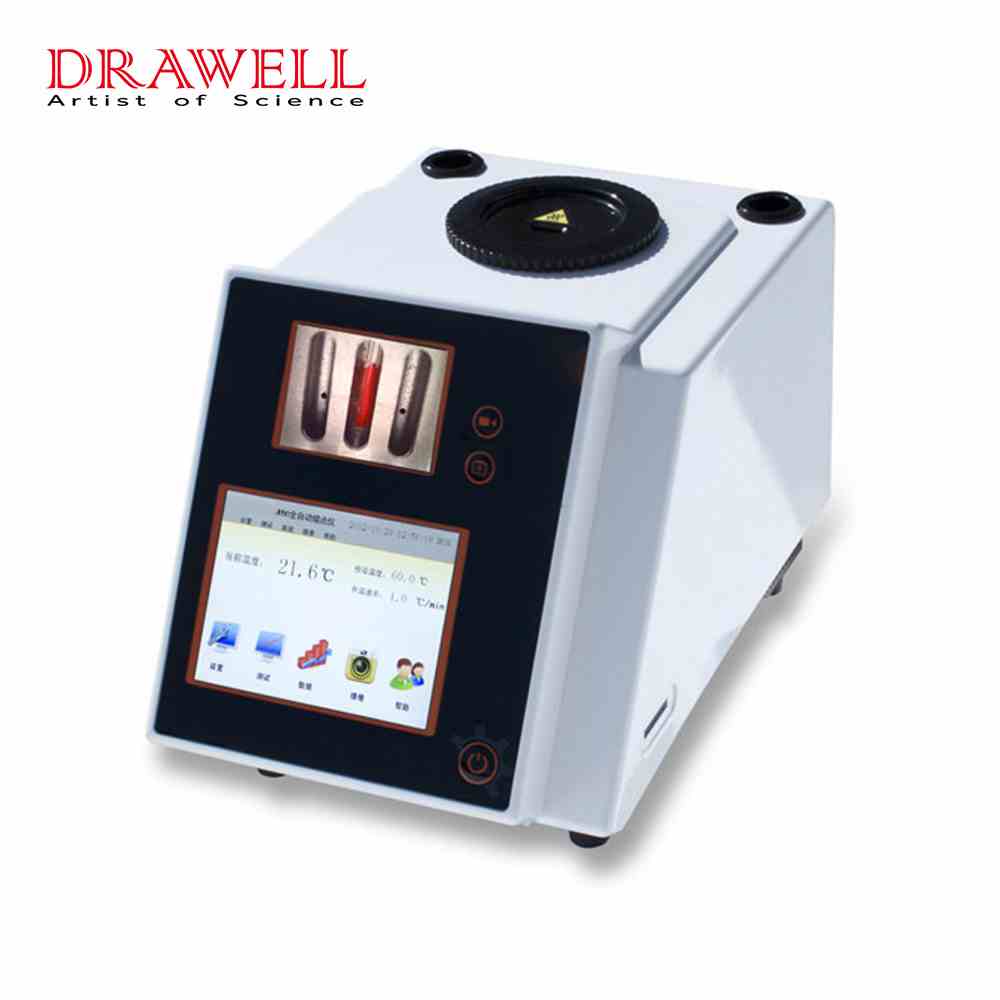

Combining high-precision temperature control technology and high-definition video camera technology, the drug melting point apparatus not only provides users with accurate, stable, and reliable test results but also brings users a convenient test experience. The high-definition video can easily see the whole process of sample melting, which is convenient for users to accurately measure the melting point and melting distance of samples.

The drug melting point apparatus adopts the capillary tube specified in the Pharmacopoeia as the sample tube and the liquid temperature transfer method and uses a computer to control the temperature rise. It is reliable in operation, high in temperature control accuracy, accurate in measurement, good in reproducibility, and easy to operate. The provisions and requirements for the instruments, utensils, and determination methods of the melting point determination method.

Common Fault Analysis and Solution of Drug Melting Point Apparatus

1. The final melting temperature display window does not display a reading.

Common Fault Description:

The temperature keeps rising, but the ammeter does not move toward full scale or fails to hit the head. So it is unable to achieve final fusion.

Fault analysis of the drug melting point apparatus

(1) The brass tube is placed in the wrong position, blocking the light path. (2) The light source is wrong, the bulb is broken, the light path is not correct, the light is scattered, and the light energy is insufficient.

Method: The light path should be adjusted.

2. The ammeter does not return to zero after inserting the capillary

After the melting point apparatus is inserted into the capillary, the ammeter should be zero, because the medicine in the capillary blocks the light path. After the medicine is melted, the light passes through the glass capillary to reach the photocell, and the photosensitive output current of the photocell realizes the final melting display. At the same time, the output current of the photocell makes the ammeter hit from zero to full scale. If the instrument’s ammeter does not return to zero when the capillary is initially inserted, the device is unusable.

Now analyze the possible reasons why the ammeter does not return to zero after the capillary is inserted:

- There are foreign objects in the brass tube where the capillary is placed. Keep the capillary out of place. Foreign matter (usually a broken glass capillary) can be pulled out with a thin copper wire.

- The resistance is not large enough, you can turn the zero adjustment knob to make it zero.

3. After pressing the initial temperature setting button, the temperature rises abnormally, fluctuates constantly, and cannot be used at all.

There are many reasons for this phenomenon, such as the temperature sensing element, the digital wheel for setting the initial temperature, and various circuit board components.

4. The fuse is blown.

Burning a fuse indicates that the current is too large, and it is often caused by a short circuit in a certain part of the circuit. Check that the load resistance is normal, check that there is no short circuit in the filter capacitor, and when checking the rectifier diode, it is found that the rectifier diode of the power supply of the heating circuit is short-circuited. In the fuse tube with the same parameters as the original, the instrument returns to normal.

5. The equipment is normal but the measured value is abnormal.

It can be calibrated with standard samples and adjusted repeatedly. It is usually caused by the user using a new capillary of a different batch.

6. The heating table is not hot.

The reason why the heating table is not hot may be that the heating wire is blown, or the fuse may be blown. In addition, the SCR may be damaged. When the heating wire is blown out, rewind the heating wire with a nickel-chromium wire with a diameter of 0.3 mm, and place a mica paper with a thickness of 0.5 mm in the middle, and the effect is very good.

It can also be fired with the heating wire of the electric iron core and the insulating mica paper. The conduction angle of the thyristor controls the size of the heating current. When the thyristor is damaged, the heating table will not be hot, and the thyristor needs to be replaced.