Ever wondered how scientists measure the thickness or resistance of a liquid to flow? Viscosity is a crucial property for various fluids. To accurately measure viscosity, viscometers are indispensable tools. Among the array of viscometry methods available, digital rotational viscometers stand out for their precision, efficiency, and ease of use. In this article, we delve into the significance of digital rotational viscometry, exploring why it’s the preferred choice for many applications and how it operates.

Understanding Viscosity

What is Viscosity?

Viscosity is a fluid’s resistance to flow. Simply put, it determines how easily a substance flows. High viscosity fluids, like honey or molasses, flow sluggishly, while low viscosity fluids, such as water or alcohol, flow more freely. Understanding viscosity is crucial across industries as it influences product quality, processing efficiency, and even consumer experience.

Traditional Viscometry Methods

Traditional viscometry methods, including capillary, rotational, falling ball, and vibrational viscometry, each have unique principles and limitations.

- Capillary viscometry relies on fluid flow through a narrow tube, but its calibration and susceptibility to temperature variations limit its utility.

- Rotational viscometry measures torque on a rotating spindle, but manual operation and sample constraints restrict its accuracy.

- Falling ball viscometry determines viscosity based on the time a ball takes to fall through a fluid-filled tube, but it’s limited to transparent fluids and prone to turbulence errors.

- Vibrational viscometry assesses damping of oscillations in a vibrating probe, but it requires precise calibration and may be affected by external vibrations.

While traditional methods are simple and cost-effective, they often lack the accuracy and versatility demanded by modern applications. As such, the emergence of digital rotational viscometers, with their automated operation and real-time analysis capabilities, has addressed many of these limitations, offering enhanced precision and efficiency in viscosity measurement across various industries.

Why Choose Digital Rotational Viscometry?

Digital rotational viscometry offers several advantages over traditional viscometry methods, making it the preferred choice for many applications:

- Precision and Accuracy: Digital rotational viscometers provide highly accurate and repeatable viscosity measurements. Their automated operation reduces human error, ensuring reliable data for research, development, and quality control purposes.

- Efficiency and Automation: These viscometers streamline the measurement process with automated functionalities, minimizing the time and effort required for viscosity analysis. Users can set parameters, initiate measurements, and obtain results efficiently, enhancing productivity.

- Versatility: Digital rotational viscometers can handle a wide range of sample types, viscosities, and temperatures. Whether analyzing Newtonian or non-Newtonian fluids, low or high viscosity samples, these instruments offer flexibility across diverse industries, from pharmaceuticals to cosmetics to food processing.

- Real-time Data Analysis: Many digital rotational viscometers come equipped with software for real-time data analysis. Users can monitor viscosity changes instantly, analyze trends, and make informed decisions promptly, improving process control and optimization.

- Cost-effectiveness: While initial investment costs may be higher compared to traditional viscometers, the long-term benefits of accuracy, efficiency, and reduced maintenance make digital rotational viscometers a cost-effective solution. They minimize downtime, decrease the need for manual interventions, and contribute to overall operational savings.

- Compliance and Standardization: Digital rotational viscometers often adhere to industry standards and regulations, ensuring compliance with quality control requirements. Standardized procedures and reporting capabilities facilitate regulatory audits and certification processes, bolstering confidence in product quality and consistency.

In summary, digital rotational viscometry offers unparalleled precision, efficiency, versatility, and compliance benefits, making it the preferred choice for viscosity measurement in modern industrial applications.

How Digital Rotational Viscometers Work?

Components of a Digital Rotational Viscometer System

A digital rotational viscometer system comprises several key components, each playing a crucial role in accurately measuring viscosity. These components typically include:

1. Rotating Spindle or Rotor:

- The rotating spindle or rotor is immersed in the sample fluid during measurement.

- It applies shear stress to the fluid, inducing flow and deformation.

- The geometry and material of the spindle may vary depending on the viscosity range and sample characteristics.

2. Torque Sensor:

- The torque sensor measures the resistance or torque experienced by the rotating spindle.

- It detects the force required to overcome the viscosity of the sample fluid.

- The torque sensor’s sensitivity and accuracy are essential for precise viscosity measurements.

3. Drive System:

- The drive system controls the rotation speed of the spindle or rotor.

- It ensures consistent and accurate rotation rates during viscosity measurements.

- The drive system may feature variable speed settings to accommodate different sample types and viscosity ranges.

4. Temperature Control

- Temperature control mechanisms maintain the sample at a constant temperature throughout the measurement process.

- Consistent temperature conditions are crucial for accurate viscosity readings, as viscosity often varies with temperature.

- Heating or cooling elements, along with temperature sensors and controllers, regulate the sample temperature within the viscometer chamber.

5. Display and Interface

- The display and interface provide a user-friendly platform for controlling the viscometer and viewing measurement results.

- Digital rotational viscometers typically feature LCD screens or touch panels for easy navigation and data visualization.

- The interface may allow users to set parameters, initiate measurements, and analyze data in real-time.

6. Software

- Digital rotational viscometers often come equipped with dedicated software for data acquisition, analysis, and reporting.

- The software may offer advanced features such as viscosity curve plotting, viscosity profile storage, and data export capabilities.

- Real-time data processing and analysis enhance productivity and enable users to make informed decisions quickly.

7. Sample Chamber or Cup

- The sample chamber or cup holds the sample fluid during viscosity measurements.

- It may feature interchangeable spindles or rotor attachments to accommodate different sample volumes and viscosities.

- The chamber’s design and material should minimize sample contamination and facilitate easy cleaning between measurements.

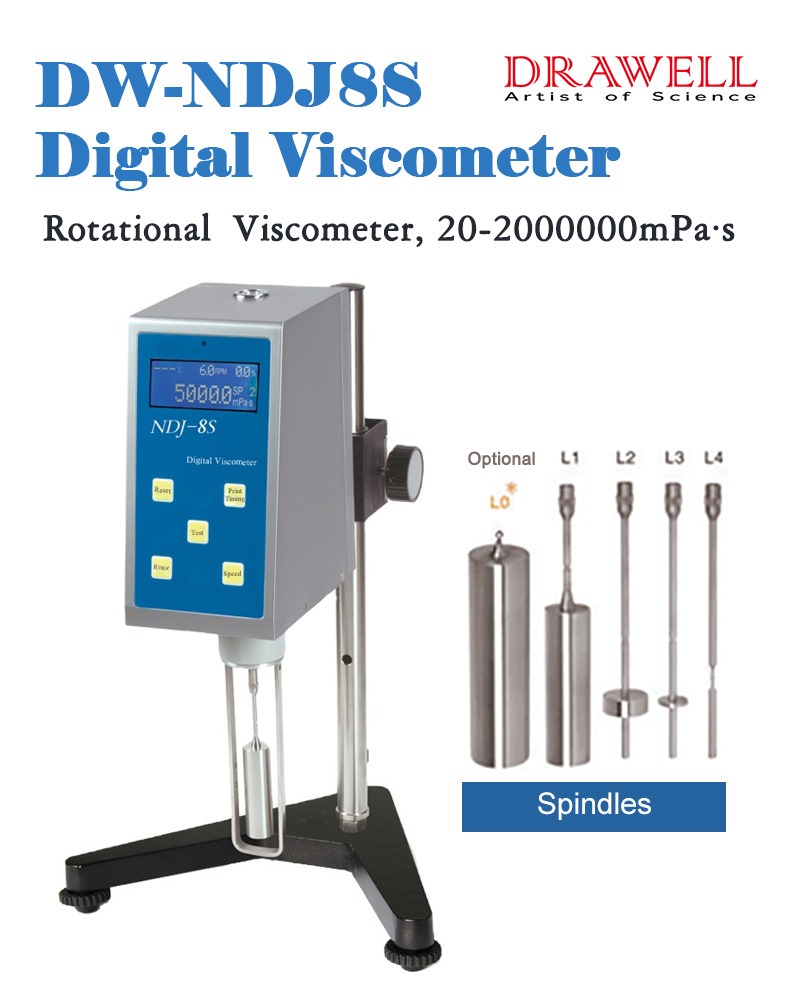

8. Optional Accessories

- Additional accessories such as temperature probes, sample holders, and protective covers may be available to enhance the functionality and safety of the viscometer system.

- Accessories tailored to specific applications or sample types may further optimize performance and measurement accuracy.

These components work together synergistically to enable accurate, reliable, and efficient viscosity measurements in digital rotational viscometers, making them invaluable tools for a wide range of industrial and scientific applications.

Principles of Digital Rotational Viscometers

The principles of digital rotational viscometers are based on the relationship between shear stress, shear rate, and viscosity. Here’s a breakdown of how digital rotational viscometers work:

- Shear Stress and Shear Rate:

Shear stress refers to the force per unit area exerted on a fluid when subjected to shear forces, such as those generated by the rotation of a spindle or rotor.

Shear rate represents the rate at which adjacent layers of fluid move relative to each other due to the applied shear stress.

- Viscosity Measurement:

Digital rotational viscometers measure viscosity by quantifying the resistance of a fluid to flow under applied shear stress.

As the spindle or rotor rotates within the sample fluid, it generates shear stress, causing the fluid to deform and flow.

The torque sensor in the viscometer measures the resistance or torque experienced by the rotating spindle due to the viscosity of the sample.

- Newton’s Law of Viscosity:

Digital rotational viscometers adhere to Newton’s Law of Viscosity, which states that the shear stress in a fluid is directly proportional to the shear rate and viscosity.

Mathematically, this relationship is expressed as τ = μ * du/dy, where τ represents shear stress, μ represents viscosity, and du/dy represents shear rate.

- Calibration and Conversion:

Digital rotational viscometers are calibrated using standard reference fluids with known viscosities.

By correlating the torque readings obtained from the viscometer with the known viscosity values of the calibration fluids, a calibration curve or conversion factor is established.

This calibration curve or conversion factor is then used to convert the measured torque into viscosity values for unknown samples.

- Digital Display and Analysis:

The torque readings obtained by the viscometer are digitally displayed and analyzed in real-time.

Digital rotational viscometers often come equipped with software that allows users to visualize viscosity data, plot viscosity curves, and perform data analysis.

Users can monitor viscosity changes, track trends, and make informed decisions based on the real-time data provided by the viscometer.

In summary, digital rotational viscometers operate on the principles of shear stress, shear rate, and viscosity measurement, following Newton’s Law of Viscosity to quantify the viscosity of fluid samples accurately. These instruments provide reliable and real-time viscosity data, making them essential tools for various industrial and scientific applications.

Safe Operating Procedures

Safe operating procedures are essential when operating digital rotational viscometers to ensure accurate measurements and prevent accidents. Here are some key safety guidelines to follow:

- Read the Manual:

Familiarize yourself with the manufacturer’s operating instructions and safety precautions provided in the user manual before using the digital rotational viscometer.

- Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect against splashes, spills, and contact with chemicals.

- Proper Setup:

Ensure the digital rotational viscometer is set up on a stable, level surface to prevent accidental spills or tip-overs during operation.

Verify that all connections, including power and data cables, are secure and properly connected.

- Sample Handling:

Handle samples with care to prevent spills and contamination of the viscometer components.

Use caution when transferring samples into the viscometer chamber to avoid spills or splashes.

Do not overfill the sample chamber, as this may lead to sample leakage or interference with the rotating spindle.

- Temperature Control:

Follow the manufacturer’s guidelines for temperature control to maintain the sample at the specified temperature range during viscosity measurements.

Avoid exposure to extreme temperatures or rapid temperature changes, which may damage the viscometer components or affect measurement accuracy.

- Spindle Installation and Removal:

Handle spindles or rotor attachments with care when installing or removing them from the viscometer.

Ensure the spindle is properly aligned and securely attached to the viscometer drive system to prevent accidents or damage to the equipment.

- Power Safety:

Only use the digital rotational viscometer with the specified power source and voltage rating indicated by the manufacturer.

Avoid using damaged power cords or adapters, and never attempt to repair or modify electrical components while the viscometer is powered on.

- Cleaning and Maintenance:

Clean the viscometer components regularly according to the manufacturer’s recommendations to prevent buildup of sample residues or contaminants.

Turn off the viscometer and disconnect power before cleaning or performing maintenance procedures to avoid electric shock or damage to the equipment.

- Emergency Procedures:

Familiarize yourself with the location of emergency shut-off switches or buttons in case of equipment malfunction or emergencies.

Have appropriate spill cleanup materials and first aid supplies readily available in the vicinity of the viscometer.

- Training and Supervision:

Ensure that operators are properly trained in the operation, maintenance, and safety procedures of the digital rotational viscometer.

Provide supervision and guidance to inexperienced users to prevent accidents and ensure proper handling of the equipment.

By following these safe operating procedures, users can minimize risks and ensure the safe and efficient operation of digital rotational viscometers in laboratory or industrial settings.

Conclusion

Digital rotational viscometers represent a significant advancement in viscosity measurement technology, offering unparalleled accuracy, efficiency, and versatility. By harnessing the principles of shear stress and shear rate, these instruments provide invaluable insights into fluid behavior across various industries. With their automated functionalities and real-time data analysis capabilities, digital rotational viscometers have become indispensable tools for research, development, and quality control processes. By understanding the principles and proper procedures, you can effectively utilize these instruments for your viscosity measurement needs. If you are looking for digital rotational viscometers supplier, please feel free to contact Drawell. They can provide you high quality lab equipments.