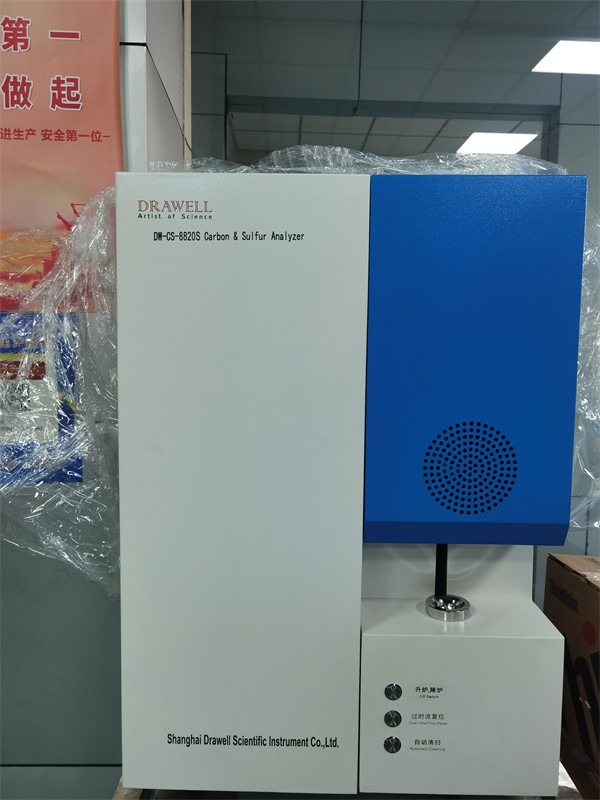

DW-CS-8820S Carbon & Sulfur Analyzer

- Measurement Range: Carbon: 0.0001%-15.0000% (can be expanded to 99.9999%)

Sulfur: 0.0001%-10.0000% (can be expanded to 99.9999%) - Sensitivity: 0.1ppm

- Analysis Time: Adjustable within 25-60 s (Normally around 35s)

- Analysis Error: Carbon meets ISO9556 standard, Sulfur meets ISO4935 standard, Meet the JJG395-97 standard at the same time

- Oscillating frequency: 20MHz

- Combustion power: 2.5KVA—7.5KVA(auto-adjust).

- working environment: Room temperature10℃~30℃. Relative humidity75%

- Voltage: AC220V±5%, frequency 50HZ±2%

Features of DW-CS-8820S Carbon & Sulfur Analyzer

Infrared detect system

The core component of infrared detection pool adopts precious metal miniature infrared light source which is high-efficient and long service life. The modulation system adopts high-precision stepper motor control by the micro controller. It is realized that long-term stability of the modulation frequency and infrared pyroelectric solid light cone sensor, Narrowband filters, these instruments make the host in high detect sensitivity, and it is effective way to detect carbon and sulfur content (ppm). it simplifies the hardware design, adding the whole host reliable and anti-interference ability.

1. The circuit design: the whole machine adopts modular design, highly integrated electronic circuits, it is very stable and reliable, meanwhile, it is adopted multi-level isolation so as to resolve high frequency interference thoroughly.

2. Sampling: it is adopted 32-bit sampling chip which belongs to America Analog Devices Company so it has fast speed and high precision.

The Communication: it is adopted USB new data exchange technology, so it greatly improves the communication speed.

The Power Supply: it is adopted high quality linear integrated military-grade power module, its output stable and there is no problem.

3. Light Source: special new type platinum infrared light source, it is efficient and its spectral stability.

4. The Analysis of Pool: Gold-plated carbon and sulfur analysis pool and High-precision pyroelectric infrared detector.

5. The Motor: special aviation motor, its thermal stability well, it has a long service life.

High Frequency Burning System

1. High Frequency Circuit: it is adopted Self-excited directional couple take power feedback, it ensures that output power is consistent, and it makes samples fully burned. It is stable.

2. High-frequency High Power Circuit Design: it is adopted 7.5kvA high-frequency pipe (actually it uses power more than 2.5kvA, cannot add sample with empty burn), it is reduced the load on high-frequency combustion systems, and it improves service life.

3. Military Products: Ceramic high-power tube and ceramic vacuum capacitor (100A).

4. High-frequency furnace output is power and power adjustable, it is suitable for all kinds of sample combustion analysis, a wide range of test materials, the whole machine adopts Import solenoid valve, high-frequency Ceramic power tube etc.

5. It adopts automatic cleaning of the burner and clean it up.

6. The control by electronic flow, the analysis of gas flow volume, the analysis of result is more stable and reliable.

7. The dust clean in the tube so as to improve measurement stable and precision.

8. Internal oxygen purification has advantages of analysis low content.

9. The main circuit over current and timeout protection. When the loop current exceeds desired point or burning time more than 60s, the system cut the main circuit by itself, and this system can avoid high-power devices overheating damage, eliminating security risks. When the status of over current disappears, the main circuit automatically resume normal.

10. The system of high-frequency combustion and infrared detection system adopt fiber connection, cutting off direct electrical connection between the two, avoiding the burning furnace or external circuit can produce interference by cable transfers to infrared monitoring system and improves the data stable.

The Random Software

1. It is adopted WINDOWS XP color surface in Chinese/English, its interface clear and its operation very convenient.

2. The independent infrared analysis software, complete functions. It has the functions of channel selection, data statistics, break point correction, results corrected, the system of detecting, system diagnostics and more than forty functions.

3. The analysis process of dynamic data integration, sampling every 32 seconds time, A/D change the frequency 150Hz-200Hz and it improves the analysis of sensitivity and accuracy.

4. The signal is tracked and its adjusted by itself.

5. Linear table of linear data high, medium and low can be corrected.

6. The process of analysis displays all kinds of real-time data and carbon and sulfur release curve.

7. There are 20 analysis channels to choose (each carbon and sulfur channels), and they can be arbitrary collocation, the choose range is very wide.

8. There are 100 carbon and sulfur release curves (each 50), it is can be stored at any time, and can be complete with carbon release curve and sulfur release curve.

9. Linearization calibration technology in full range, there are single and multi-point calibration, it can be set up one, two, three and more Linear calibration equation, and it improves Linear calibration equation and the correction of analysis data.

10. It can be communicated with data center or reported in front of the furnace.

11. Any brand of computers can communicate with this system.

12. A variety of print output mode.

13. It can communicate with any brand of electronic balance.

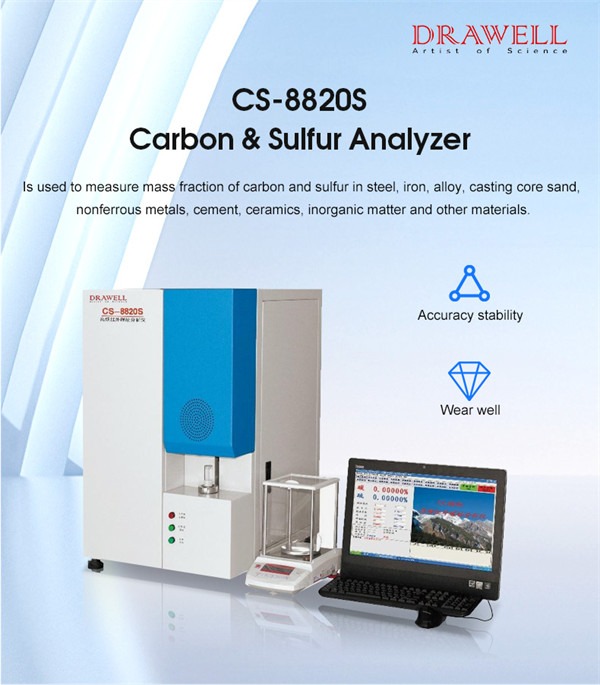

Applications of DW-CS-8820S Carbon & Sulfur Analyzer

DW-CS-8820S High-Frequency Infrared Carbon & Sulfur Analyzer is used to measure mass fraction of carbon and sulfur in steel, iron, alloy, casting core sand, nonferrous metals, cement, ceramics, inorganic matter and other materials.

Key Applications: Mainly used in steel, iron, alloy, casting core sand, nonferrous metals.

Main Configuration of DW-CS-8820S Carbon & Sulfur Analyzer

| No. | Name | Type | Quantity | Unit | Remarks |

| 1 | Infrared host | DW-CS-8820S | 1 | PC | Include in quotation |

| 3 | Computer | 1 | PC | ||

| 4 | Printer | 1 | PC | ||

| 5 | Electronic balance | Sartorius (One ten thousandth) | 1 | PC | |

| 6 | Random spare parts | See the table below | 1 | Set |

Random Spare Parts of DW-CS-8820S Carbon & Sulfur Analyzer

| No. | Name | Specification | Unit | Quantity | Note |

| 1 | Relieve Valve | YQY-6 | pcs | 1 | |

| 2 | Ceramic Crucible | 1000pcs/carton | carton | 1 | |

| 3 | Tungsten Accelerator | Low blank of C & S | bottle | 1 | |

| 4 | Pure Iron Accelerator | Low blank of C & S | bottle | 1 | |

| 5 | Quartz Crucible Holder | pcs | 2 | ||

| 6 | Dust Cleaning Tube | Meter | 1.2 | ||

| 7 | Silicone Ring | Ø40*27*7 | pcs | 1 | |

| 8 | O-Ring | 37mm*3.1mm | pcs | 2 | |

| 9 | O-Ring | 16mm*2.5mm | pcs | 2 | |

| 10 | PVC pipe | 4mm*6mm | Meter | 10 | |

| 11 | Switch | Self-locking | pcs | 1 | |

| 12 | Switch | Not Self-locking | pcs | 1 | |

| 13 | Rocker Switch | Double Row | pcs | 1 | |

| 14 | Fuse | 2A | pcs | 2 | |

| 15 | Porcelain Fuse | 20A | pcs | 2 | |

| 16 | Ash Discharge Tube | pcs | 1 | ||

| 17 | Quartz Tube | pcs | 2 | ||

| 18 | Sampling Spoon | Big, Middle, Small | set | 1 | Stainless Steel |

| 19 | Forceps | pcs | 1 | ||

| 20 | Steel Wire Brush | pcs | 1 | ||

| 21 | Paint Brush | pcs | 1 | ||

| 22 | Stainless Steel Round Brush | pcs | 3 | ||

| 23 | Vacuum Silicone Grease | bottle | 1 | ||

| 24 | Desiccant | 125kg | bottle | 1 | |

| 25 | Print Paper | A4 | pcs | 1 | |

| 26 | Screwdriver | Short Handle | pcs | 1 | |

| 27 | Multi-socket | pcs | 1 |

Installation Conditions of DW-CS-8820S Carbon & Sulfur Analyzer

Note: Installation conditions refer to the conditions that the user must prepare before the installer arrives.

1. Instrument analysis room: Away from the location of corrosive gases, dust, vibration and interference measurement such as acid and alkali

2. Analysis room area: Requires more than 3×3m

3. Working environment: indoor temperature: 10-30℃, relative humidity: <75%

4. Power supply: Requires good grounding, voltage AC220V±5%,frequency 50Hz±2% and no harmonic interference. Wiring socket 16A (Three holes), One 10A (Three holes).

5. Power Supply: Power 5kW, voltage regulation accuracy<2% (If the voltage is unstable, it can be used as a backup)

Note: If the working power supply has harmonic interference such as intermediate frequency furnace, it should be equipped with AC parameter purification power supply.

6. The working gas: Oxygen, purity﹥99.5%

7. Tool: Unpacking and general use tools

Training of DW-CS-8820S Carbon & Sulfur Analyzer

1. On-site technical training

Party A is responsible for the training of Party B personnel in operation, maintenance, daily troubles, etc., and should be able to use the instruments independently and skillfully.

2. System training

Party B may also send personnel to Party A for systematic training.2 trainers, for a period of not less than 3 days (the specific time of the training is decided by both parties), transportation, accommodation and self-care.

Training content includes:

- Carbon and sulfur analyzer analysis principle and method.

- Structure and characteristics of Drawell series carbon and sulfur instruments.

- Operational skills and analytical methods for quantitative analysis of carbon and sulfur analyzers.

- Analysis condition setting, working curve, correction, etc.

- Daily troubleshooting.

- Instrument maintenance and care.

Complete After Sales Service for DW-CS-8820S Carbon & Sulfur Analyzer

1. After-sales service is directly responsible for the local dealers. If there is no dealer in this area, Drawell will be responsible for the repair.

2. The warranty period shall be 12 months from the date of acceptance of the goods or 12 months from the date of receipt of the goods by the buyer, whichever comes first. Lifelong service and various spare parts are available for many years.

3. When the user encounters a problem, he can call the service hotline of 0086-18352836805, and the after-sales service personnel will guide the solution within 24 hours by telephone.

4. When it is confirmed that the instrument is faulty and needs on-site maintenance, the service personnel will not give a solution within 2 working days, and the product will be excluded within 7 working days. In case of special circumstances, it is necessary to arrive at the on-site repair within the agreed time with the customer.

5. Content of on-site repair service: Repair instrument failure, instrumentation indicator, training function operation, to introduce the use experience and overhaul.

6. Provide service communication to users on a regular basis: Introduce the development of the company and the new technical functions of the instrument, introduce the test report and experience of users from all walks of life

7. DW-CS-8820S software is operating software based on the WINDOWS platform. When the operating software version needs to be updated, Drawell provides an upgraded version for free.

Note: Matters not covered in this agreement, the two sides negotiated through friendly negotiation.