X-ray fluorescence (XRF) spectrometry is a powerful analytical technique used to determine the elemental composition of materials. Among the various types of XRF spectrometers available, Wavelength Dispersive X-ray Fluorescence (WDXRF) and Energy Dispersive X-ray Fluorescence (EDXRF) are the most common. Both methods have distinct technical attributes, advantages, and application areas, making the choice between them crucial depending on specific analytical needs. This article aims to compare WDXRF and EDXRF, highlighting their key differences, strengths, weaknesses, and applications to help you decide which spectrometer is best suited for your requirements.

Key Differences Between WDXRF and EDXRF

Technical Differences

WDXRF and EDXRF differ fundamentally in how they detect and measure X-rays emitted by the sample.

WDXRF (Wavelength Dispersive XRF): In WDXRF, X-rays emitted from the sample are dispersed into their component wavelengths by a crystal diffraction grating. These wavelengths are then detected by a detector positioned at a specific angle corresponding to the wavelength of interest. This method offers high resolution and precise quantification due to its ability to differentiate closely spaced wavelengths.

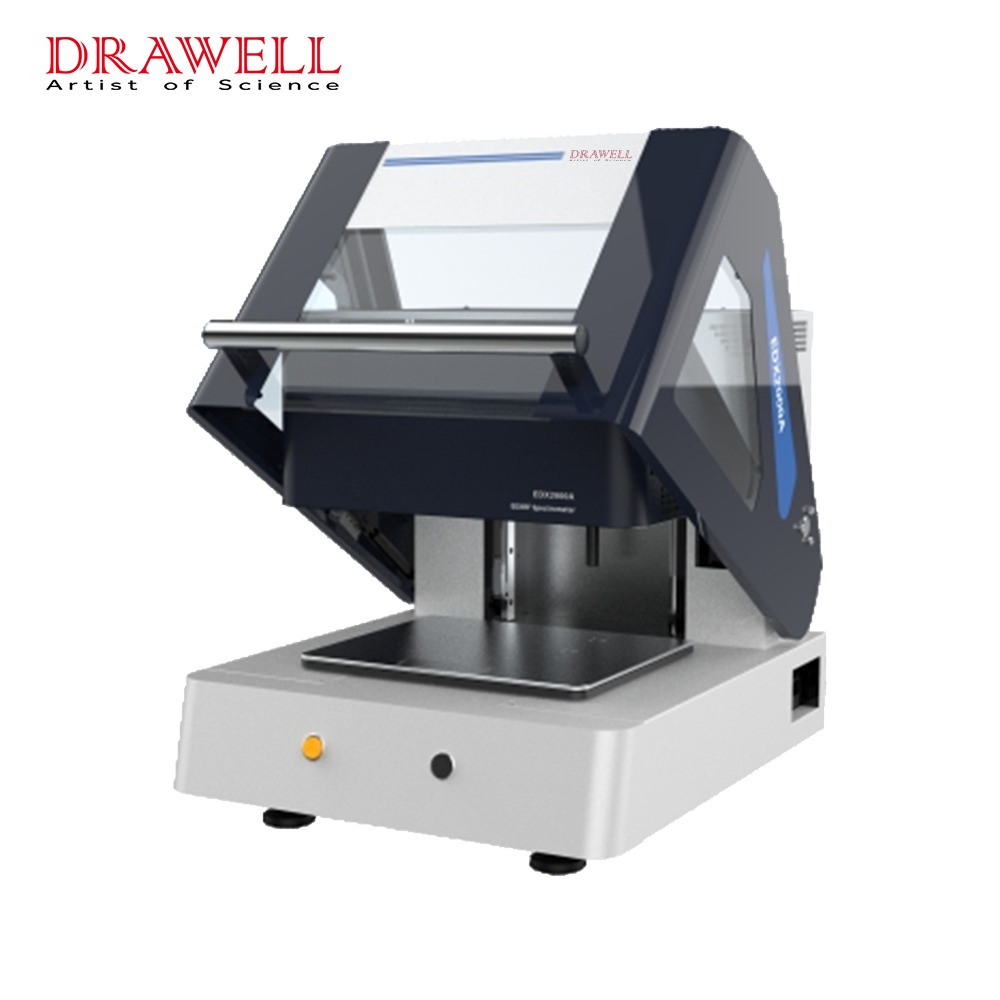

EDXRF (Energy Dispersive XRF): In EDXRF, the emitted X-rays are detected directly by a solid-state detector that measures their energy. The detector converts the energy of each photon into an electrical signal, which is then processed to produce a spectrum. EDXRF is generally faster because it can simultaneously detect a wide range of X-ray energies.

Strengths and Weaknesses:

| Spectrometer | Strengths | Weaknesses |

| WDXRF | High Resolution: Detailed elemental differentiation; Precise quantification | Slower Analysis: Sequential measurement; Time-consuming for multi-element samples |

| Accuracy and Precision: Reproducible results; Minimal matrix effects | Complexity and Cost: Higher initial investment; Maintenance and operation costs | |

| Lower Detection Limits: Trace element analysis | Instrument Size: Bulky equipment | |

| Elemental Range: Broad elemental coverage | ||

| EDXRF | High Resolution: Simultaneous multi-element detection; Quick turnaround | Lower Resolution: Reduced accuracy for complex samples |

| Simplicity and Cost: Ease of use; Lower initial cost | Limited light element detection | |

| Speed: Rapid analysis; High throughput | Higher detection limits; Potential interference | |

| Portability: Compact and portable |

In summary, both WDXRF and EDXRF have unique strengths and weaknesses. WDXRF excels in high-precision, detailed analysis and low detection limits, making it ideal for applications requiring rigorous accuracy. EDXRF, on the other hand, offers speed, simplicity, and portability, which are advantageous for rapid, versatile analysis in various settings. The choice between the two depends on the specific analytical needs and operational constraints of the user.

Applications Differences:

| Applications | WDXRF | EDXRF |

| Mineral Exploration and Mining | Elemental analysis of ores and minerals for mining exploration and resource assessment. | Analysis of geological samples to determine mineral composition and valuable metal concentrations. |

| Cement and Building Materials | Quality control of cement, concrete, and building materials to ensure compliance with standards. | Analysis of construction materials for elemental composition and quality assurance. |

| Metals and Alloys Analysis | Analysis of metals and alloys in metallurgical industries for composition verification and quality control. | Elemental analysis of steel, aluminum, copper, and other alloys for material characterization and quality assessment. |

| Environmental Monitoring | Soil, water, and air analysis for trace element detection and environmental pollution assessment. | Assessment of environmental samples for contamination levels, including air particulate matter and water quality. |

| Pharmaceuticals and Biomedical Research | Elemental analysis of drug formulations, biomaterials, and biological samples for pharmaceutical research and quality assurance. | Analysis of pharmaceutical products, biomaterials, and biomedical samples for compliance with regulatory standards. |

| Glass and Ceramics Production | Composition analysis of raw materials, process monitoring, and quality control in glass and ceramics manufacturing. | Quality assurance of glass and ceramic products, including composition analysis and defect detection. |

| Consumer Product Testing | / | Testing of consumer goods, such as toys, electronics, textiles, and food packaging, for compliance with safety standards and regulations. |

| Art and Archaeology | Non-destructive elemental analysis of artifacts, paintings, sculptures, and historical objects for material composition and authenticity verification. | Analysis of artworks, archaeological artifacts, and cultural heritage objects for provenance determination and conservation purposes. |

| Petroleum Industry | / | Elemental analysis of crude oil, petroleum products, and lubricants for quality control and contamination detection. |

| Recycling and Waste Management | / | Sorting and analysis of recycled materials, such as metals, plastics, and electronic waste, for efficient recycling and waste management. |

| Food and Agriculture | / | Elemental analysis of soil, fertilizers, animal feeds, and food products for nutrient assessment, contaminant detection, and food safety assurance. |

These applications highlight the versatility and utility of both WDXRF and EDXRF spectrometers across various industries and research fields, catering to diverse analytical needs and requirements.

Key Factors to Consider When Choosing the Right XRF Spectrometer

When selecting the appropriate XRF (X-ray fluorescence) spectrometer for your analytical needs, several key factors should be considered to ensure the instrument meets your requirements effectively. Here are the key factors to consider:

Analytical Requirements:

Resolution and Sensitivity: Determine the required level of resolution and sensitivity for your analysis. Higher resolution spectrometers, such as WDXRF, are suitable for detailed elemental differentiation, while lower resolution instruments like EDXRF may suffice for broader analysis.

Elemental Range: Consider the range of elements you need to analyze. Ensure the spectrometer covers the elements of interest, especially if your samples contain both light and heavy elements.

Detection Limits: Evaluate the detection limits of the spectrometer for the elements you need to detect, especially if you require trace element analysis.

Sample Types and Matrices:

Sample Matrix: Consider the type of samples you will be analyzing (e.g., solids, liquids, powders) and their matrices (e.g., geological, environmental, industrial). Choose a spectrometer capable of handling your specific sample types and matrices.

Matrix Effects: Evaluate the susceptibility of the spectrometer to matrix effects, which can affect the accuracy and precision of results, especially in complex sample matrices.

Throughput and Productivity:

Analysis Speed: Determine the required analysis throughput and turnaround time. EDXRF spectrometers typically offer faster analysis times compared to WDXRF due to simultaneous multi-element detection.

Sample Handling: Consider the ease of sample preparation and loading, especially if you have a high sample throughput or need to analyze a large number of samples.

Accuracy and Precision:

Calibration and Standards: Assess the calibration procedures and availability of certified reference materials for accurate calibration and validation of results.

Repeatability and Reproducibility: Evaluate the instrument’s repeatability and reproducibility to ensure consistent and reliable results over time.

Cost and Budget:

Initial Investment: Consider the initial cost of the spectrometer, including purchase price, installation, and setup costs. Determine whether the investment aligns with your budget constraints.

Operating Costs: Factor in ongoing operational costs, including maintenance, consumables, and energy consumption, to ensure the instrument remains within budget over its lifecycle.

Ease of Use and Training:

User Interface: Evaluate the user interface and software provided with the spectrometer. Choose a system that is intuitive and user-friendly, minimizing the need for extensive training.

Technical Support: Consider the availability of technical support, training resources, and service agreements to ensure reliable operation and troubleshooting assistance when needed.

By carefully considering these key factors, you can choose the right XRF spectrometer that meets your analytical needs, budget constraints, and regulatory compliance requirements effectively.

Conclusion

Choosing between WDXRF and EDXRF spectrometers depends on your specific analytical needs and operational context. WDXRF offers high resolution and precision, making it ideal for applications requiring detailed elemental analysis. In contrast, EDXRF provides faster, more versatile analysis, suitable for a wide range of applications and fieldwork. By carefully considering your requirements and the strengths and weaknesses of each method, you can select the spectrometer that best fits your needs, ensuring accurate and efficient elemental analysis.