Accurate moisture measurement ensures product quality, prevents spoilage, and maintains compliance with industry standards. Among the various moisture measurement technologies available, halogen moisture analyzers are widely recognized for their precision and efficiency. However, other types of moisture analyzers, including infrared, microwave, capacitance, and resistance-based analyzers, also serve essential roles in different applications. This article compares halogen moisture analyzers with other moisture measurement methods, highlighting their advantages, limitations, and best-use scenarios.

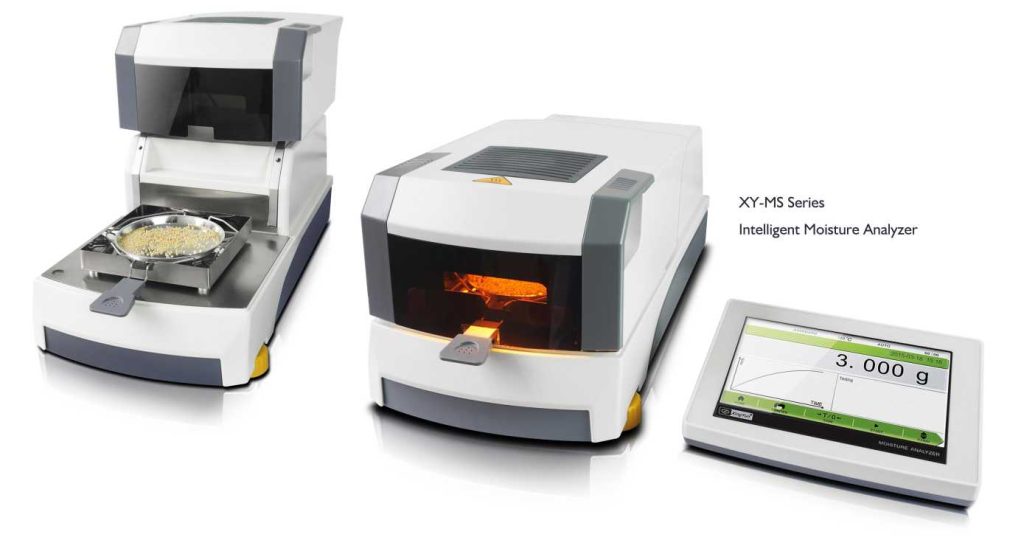

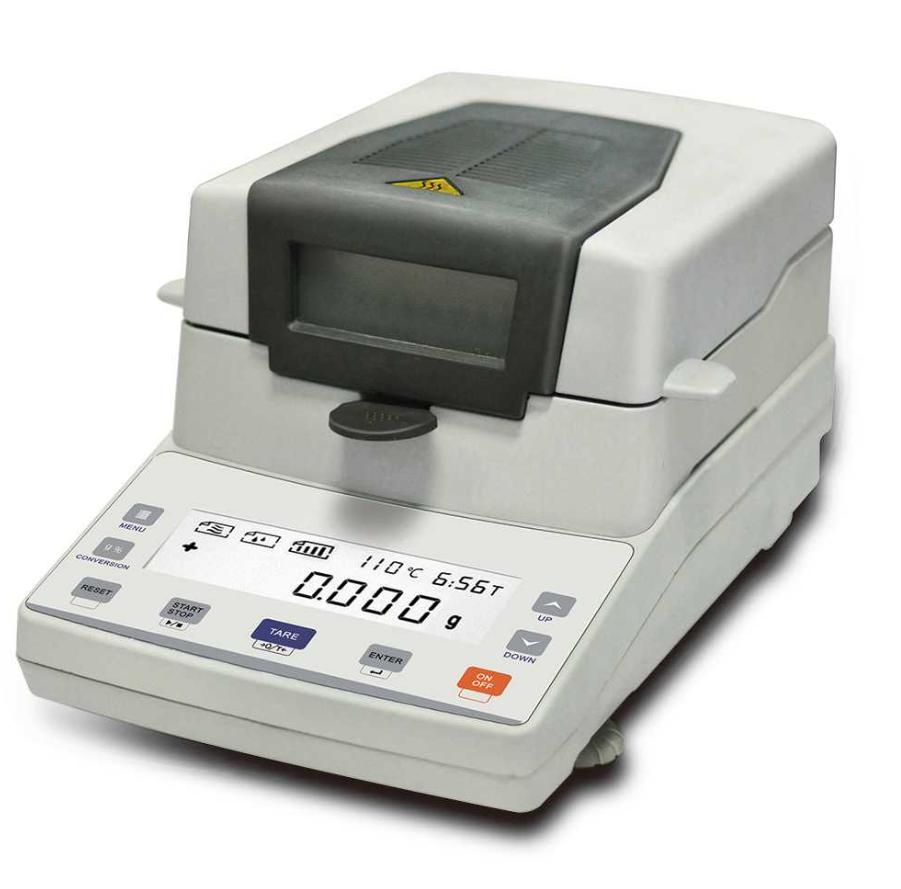

What are Halogen Moisture Analyzers

Halogen moisture analyzers are advanced instruments used to determine the moisture content of a sample by employing a thermogravimetric (loss-on-drying) method. These analyzers utilize a halogen lamp as a heat source to rapidly dry the sample, while continuously measuring its weight loss to calculate moisture content. They are widely used in industries such as food processing, pharmaceuticals, chemicals, agriculture, and plastics, where precise moisture measurement is essential for quality control and compliance with industry standards.

How them Works

Halogen moisture analyzers operate based on the thermogravimetric (loss-on-drying) method, where a halogen lamp is used to heat a sample and measure its moisture content through weight loss.

The process begins by placing a small sample on a weighing pan inside the moisture analyzer. The device records the initial weight before starting the drying process. The halogen lamp emits infrared radiation, which heats the sample, causing moisture to evaporate. This drying method ensures even heat distribution, reducing the chances of overheating or burning the sample.

Throughout the heating process, the built-in balance continuously measures the sample’s weight. The moisture content is determined by comparing the initial and final weights, with the difference representing the evaporated moisture. The moisture analyzer automatically calculates the moisture percentage and displays the final result on the screen.

The process is typically fast and precise, with results available within minutes. Many halogen moisture analyzers feature programmable drying profiles, allowing users to customize settings based on different materials. This makes them ideal for industries such as food, pharmaceuticals, chemicals, and plastics, where accurate moisture analysis is essential for quality control.

Advantages

- High Accuracy: Provides precise moisture content analysis.

- Rapid Testing: The halogen lamp ensures fast drying and quick results.

- Consistent & Repeatable Results: Ideal for quality control in various industries.

- Automated Operation: The automatic moisture analyzer features programmable settings for ease of use.

- Versatile Applications: Suitable for measuring moisture in powders, granules, pastes, and liquids.

Limitations

- Higher Cost: More expensive than basic moisture analyzers.

- Limited Portability: Generally designed for laboratory or industrial settings, not for field use.

- Small Sample Size: Requires controlled sample sizes for accurate measurement.

Common Applications

- Food Industry: Measuring moisture in grains, dairy, coffee, and baked goods.

- Pharmaceuticals: Ensuring proper moisture levels in tablets and powders.

- Chemicals & Plastics: Controlling moisture in raw materials and polymers.

- Agriculture: Determining moisture content in soil, seeds, and animal feed.

Key Differences Between Halogen Moisture Analyzers and Other Moisture Analyzers

This chart offers a side-by-side comparison of halogen moisture analyzers and other common moisture analyzers, outlining their unique features, advantages, and ideal applications.

| Feature | Halogen Moisture Analyzers | Infrared Moisture Analyzers | Microwave Moisture Analyzers | Capacitance Moisture Meters | Resistance Moisture Meters |

| Heating Method | Halogen lamp (infrared radiation) | Infrared radiation | Microwave energy | Dielectric constant measurement | Electrical conductivity |

| Speed of Analysis | Fast (few minutes) | Moderate (slower than halogen) | Very fast (ideal for bulk materials) | Moderate (depends on material) | Slow to moderate (depends on material) |

| Accuracy | High, precise weight loss measurement | High, but slower than halogen | High, but less accurate for small samples | Moderate (less precise than halogen) | Moderate (less accurate for low moisture) |

| Sample Size | Small to medium | Small to medium | Large (bulk material) | Small to medium (wood, grains, etc.) | Small to medium (wood, concrete, etc.) |

| Portability | Not typically portable (lab use) | Can be portable (handheld models) | Usually stationary (lab use) | Portable (ideal for field use) | Portable (ideal for field use) |

| Material Suitability | Powders, granules, pastes, some liquids | Powders, granular materials | Bulk materials, especially agriculture | Wood, textiles, paper, grain | Wood, concrete, building materials |

| Cost | Higher (due to advanced technology) | Moderate | Higher (specialized technology) | Lower (affordable for general use) | Lower (affordable for basic applications) |

| Application | Quality control in labs, manufacturing | Industry-specific, especially food & chemicals | Agriculture, biomass, bulk materials | Field measurements (wood, grains) | Field measurements (wood, construction materials) |

| Non-destructive Testing | Yes | Yes | No | Yes | Yes |

Key Factors to Consider for Choosing the Right Moisture Analyzer

This chart helps in selecting the best moisture analyzer based on specific application needs, accuracy, and budget constraints.

| Factor | Description | Best Suitable Moisture analyzer |

| Measurement Accuracy | High precision needed for critical industries like pharmaceuticals and food. | Halogen, Infrared |

| Speed of Analysis | Fast results required for production efficiency. | Halogen, Infrared, Microwave |

| Material Type | Type of material being tested (powders, grains, wood, etc.). | Halogen (powders), Microwave (bulk), Capacitance (wood, textiles) |

| Portability | Need for field or lab-based testing. | Capacitance, Resistance (handheld); Halogen, Infrared (lab use) |

| Depth of Measurement | Surface-level vs. deep moisture detection. | Microwave (deep), Capacitance (moderate), Halogen/Infrared (surface) |

| Non-Destructive Testing | Whether the material should remain intact after testing. | Microwave, Capacitance |

| Sample Size | Small vs. bulk sample requirements. | Halogen/Infrared (small), Microwave (bulk), Capacitance/Resistance (varies) |

| Cost Considerations | Budget limitations and cost-effectiveness. | Capacitance, Resistance (low cost); Halogen, Infrared (higher cost) |

| Industry Compliance | Need to meet regulatory standards in food, pharmaceuticals, etc. | Halogen, Infrared |

| Ease of Use | Simplicity of operation and automation features. | Capacitance, Resistance (easy); Halogen, Infrared (automated settings) |

Wrap Up

Halogen moisture analyzers excel in accuracy, speed, and reliability, making them a preferred choice for industries that require precise moisture measurement. However, depending on the application, other moisture analyzers such as microwave, infrared, capacitance, and resistance-based devices may offer better portability, cost-effectiveness, or bulk measurement capabilities. Choosing the right moisture analyzer depends on application needs, material type, required accuracy, portability, cost considerations etc. Understanding these factors ensures the selection of a moisture analyzer that meets both technical and operational requirements.

With precise halogen heating technology, halogen moisture analyzers provided by Drawell ensure efficient drying, real-time weight measurement and repeatable results. They are ideal for quality control and compliance with advanced features, user-friendly operation and superior performance for laboratory and industrial applications.