Biosafety cabinets are categorized into Class I, II, and III, each offering different levels of protection and suitable for specific applications. Understanding the differences among these classes is essential for selecting the right biosafety cabinet for your laboratory’s needs.

Understanding Biosafety Cabinets

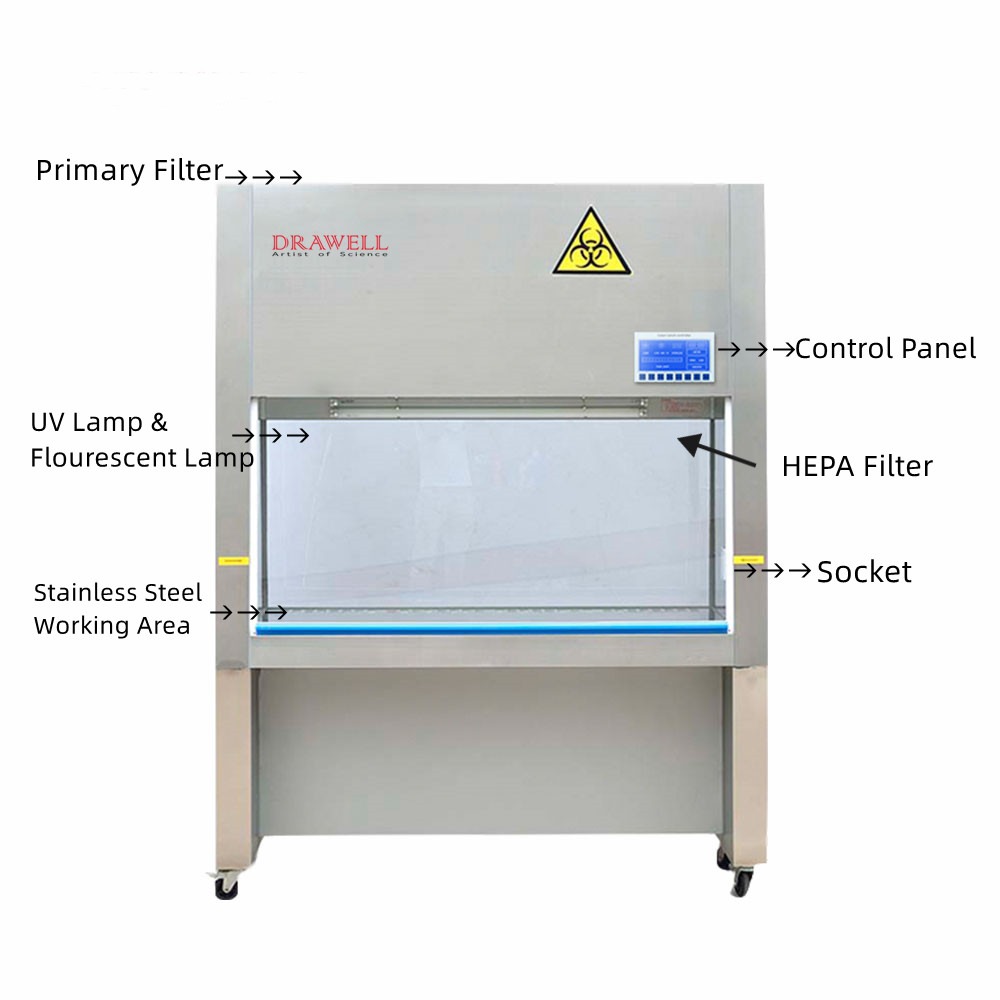

Biosafety cabinets are enclosed, ventilated laboratory workspaces designed to protect personnel, the environment and sometimes the work materials from exposure to biohazardous agents or infectious materials. They use high-efficiency particulate air (HEPA) filtration and controlled airflow to prevent contamination and contain airborne pathogens. Biosafety cabinets are essential in microbiology, biomedical research, and pharmaceutical labs, and are categorized into Class I, II, and III based on the level of protection they provide.

What are Class I Biosafety Cabinets

Class I biosafety cabinets provide protection for personnel and the environment but do not offer product protection. These cabinets operate with unrecirculated airflow and use a High-Efficiency Particulate Air (HEPA) filter to clean the exhaust air before it is released into the environment.

Key Features:

- Inward airflow (typically 75 linear feet per minute)

- HEPA-filtered exhaust

- No protection for the work material inside the cabinet

Applications:

- Safe handling of low- to moderate-risk biological agents (Biosafety Level 1 and 2)

- Use with non-volatile toxic chemicals when appropriate filters are in place

- Common in teaching laboratories or for procedures generating aerosols

Limitations:

- No product protection: unsuitable for sterile culture work.

- Not suitable for volatile chemicals or toxic vapors, unless ducted with proper exhaust systems.

- Limited to procedures that do not generate aerosols or require high containment.

What are Class II Biosafety Cabinets

Class II biosafety cabinets are the most commonly used type in microbiological and biomedical labs. They provide protection for personnel, the environment, and the product. Air is drawn into the front grille (personnel protection), while downward HEPA-filtered laminar airflow protects the materials inside the cabinet.

Class II cabinets are further divided into Type A1, A2, B1, and B2, based on airflow and exhaust system design.

Key Features:

- HEPA-filtered downflow and exhaust

- Partial recirculation of air (except B2 type, which is 100% exhausted)

- Front access opening with inward airflow

Applications:

- Work involving BSL-1, BSL-2, and BSL-3 agents

- Tissue culture, pharmaceutical testing, diagnostics

- Suitable when product protection is critical

Types of Class II Biosafety Cabinets

| Type | Key Feature | Typical Use |

| A1 Cabinets | Recirculates ~70% air inside; low exhaust velocity | Microbiological work (no toxic chemicals) |

| A2 Cabinets | Higher exhaust velocity; ducted or recirculating | Common in research and clinical labs |

| B1Cabinets | 30% recirculation; 70% ducted exhaust | Handling small amounts of toxic chemicals |

| B2 Cabinets | 100% exhausted outside; no air recirculation | Toxic fumes and volatile chemicals |

What are Class III Biosafety Cabinets

Class III cabinets, or “glove boxes,” are gas-tight enclosures offering the highest level of protection for personnel, environment, and product. All operations are conducted through attached gloves, and the cabinet is maintained under negative pressure.

Key Features:

- Fully enclosed and gas-tight

- HEPA filtration for both intake and exhaust air

- Operated through sealed gloves

- Often connected to double-door autoclaves or transfer boxes

Applications:

- Handling of high-risk biological agents (BSL-4)

- Research involving unknown or highly infectious agents

- High-containment labs and biodefense applications

Limitations:

- High cost of purchase, installation, and maintenance

- Requires specialized infrastructure (e.g., secure room, air handling systems)

- Slower workflow due to glove manipulation and pass-through procedures

- Operators require training to maintain performance and safety

Comparison among Class I, II and III Biosafety Cabinets

| Feature | Class I | Class II | Class III |

| Personnel Protection | Yes | Yes | Yes |

| Product Protection | No | Yes | Yes |

| Environment Protection | Yes | Yes | Yes |

| Airflow Direction | Inward | Downward laminar + inward | Sealed, negative pressure |

| Use of Gloves | No | No | Yes |

| HEPA Filters | Exhaust only | Supply and exhaust | Supply and exhaust |

| Typical Use Level | BSL-1, BSL-2 | BSL-1 to BSL-3 | BSL-4 |

| Chemical Use | Limited (if filtered) | Varies by type (A vs. B) | Yes (with proper filtration) |

Key Considerations for Choosing Among Class I, II, and III Biosafety Cabinets

- Nature of the Biological Material

One of the primary factors in choosing a biosafety cabinet is the biosafety level (BSL) of the agents being handled:

- Class I biosafety cabinets are appropriate for low- to moderate-risk (BSL-1 and BSL-2) organisms, especially when the priority is operator protection rather than product sterility.

- Class II biosafety cabinets are suitable for BSL-1 to BSL-3 agents and offer a balance of protection for personnel, environment, and product.

- Class III biosafety cabinets are required for BSL-4 organisms, typically those that are highly infectious or lack known treatments.

- Required Type of Protection

Different applications require different types of protection:

- Personnel protection is essential in all laboratory settings. All BSC classes provide this to varying degrees.

- Product protection is crucial in procedures involving sterile cultures or samples—provided by Class II and III cabinets.

Environmental protection is achieved through HEPA filtration of exhaust air, included in all three classes.

If maintaining the sterility of materials is not necessary, Class I may be sufficient. However, if both sample and personnel safety are priorities, Class II or III is necessary.

- Work Procedures and Airflow Requirements

Understanding how the cabinet handles airflow is critical:

- Class I cabinets pull air inward and exhaust it through a HEPA filter, protecting only the user and environment.

- Class II cabinets use a vertical laminar flow system, with filtered air recirculated within the cabinet to protect the product while exhausting filtered air outside or back into the lab.

- Class III cabinets are fully enclosed, gas-tight units operated with built-in gloves, providing maximum containment and safety.

If the procedure involves open handling of infectious agents or generating aerosols, Class II or III is preferred.

- Use of Hazardous Chemicals

If the laboratory work includes volatile toxic chemicals or radioactive substances, airflow and exhaust design must be considered:

- Class I can accommodate small amounts of chemicals with proper ventilation.

- Class II Type A1 and A2 are not suitable for toxic chemicals unless properly ducted.

- Class II Type B1 and B2 are better suited as they exhaust most or all of the air outside.

- Class III cabinets are safe for use with such materials when integrated with the right filters and exhaust systems.

- Laboratory Infrastructure and Maintenance

The physical setup of the laboratory and capacity for maintenance also impact the choice:

- Class I and II cabinets are relatively straightforward to install and maintain.

- Class III cabinets, on the other hand, require a dedicated containment suite, external exhaust, and specialized training for operation and upkeep.

- Budget and Operational Scale

Cost is another important consideration. Class I cabinets are the most affordable, while Class III cabinets are the most expensive due to their complexity. Class II cabinets offer a middle ground in both functionality and cost, making them the most commonly used in many laboratories.

- Compliance and Regulatory Guidelines

Compliance with biosafety cabinet standards set by agencies such as the CDC, WHO, or local health authorities is mandatory. The cabinet chosen must meet the standards required for the intended work. For example:

- Class I for minimal-risk teaching labs.

- Class II for clinical, pharmaceutical, and diagnostic settings.

- Class III for high-containment labs or government research facilities.

Summary

- For basic protection without product sterility, Class I is sufficient.

- For versatile protection of personnel, environment, sample, etc, across a range of applications, Class II is usually the best fit.

- For work with the most dangerous pathogens, only Class III offers the necessary level of containment.

Final Thoughts

The choice of a biosafety cabinet depends heavily on the biological agents in use and the required level of protection. Careful assessment of laboratory protocols and biosafety levels will ensure the right cabinet is selected to maintain both safety and operational efficiency.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.