Centrifugation is a critical process used in laboratories and industries to separate components of a mixture based on their densities. By applying centrifugal force, particles are separated from solutions or liquids. Centrifuges come in various types, with low speed and high speed centrifuges being two primary categories. Understanding the differences, advantages, and disadvantages of these centrifuges is crucial for selecting the right equipment for specific applications. This article provides a comparative analysis of low speed and high speed centrifuges and highlights why Drawell’s centrifuges are a superior choice.

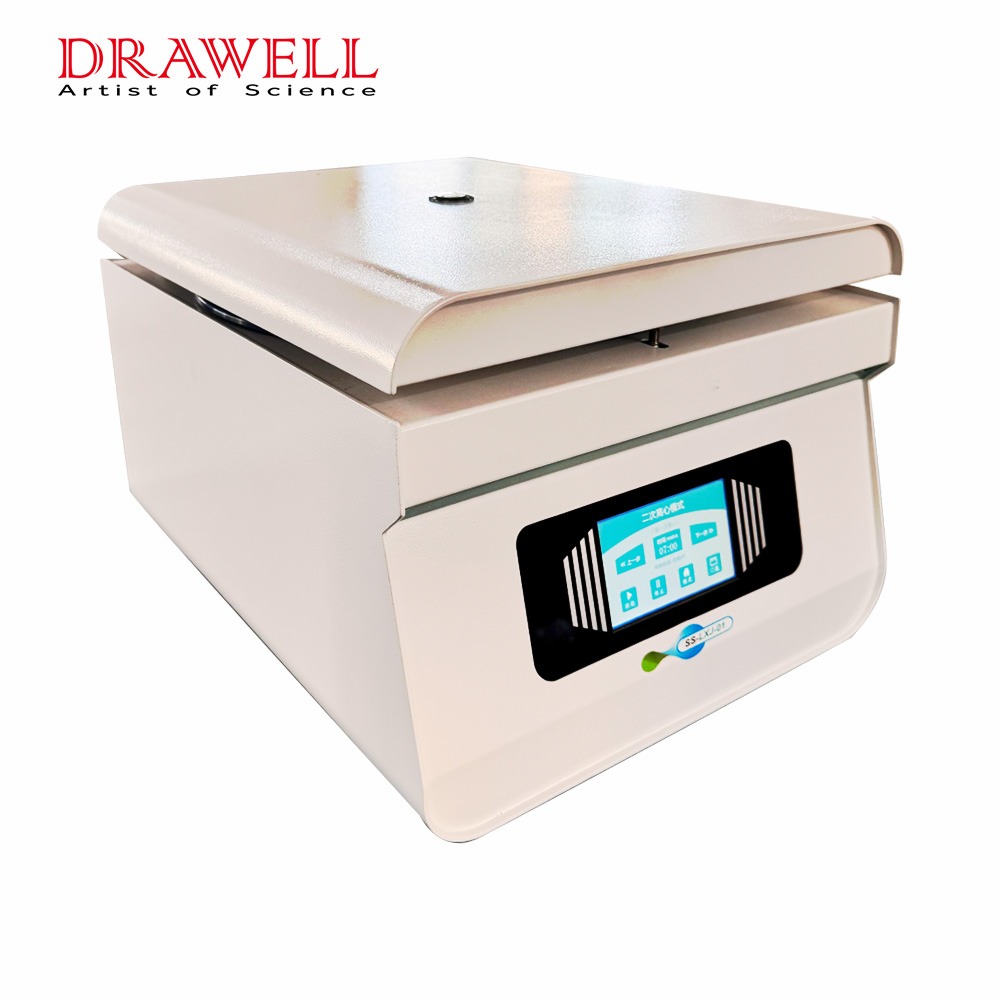

Low Speed Centrifuge

A low speed centrifuge typically operates at speeds ranging from 300 to 6,000 revolutions per minute (rpm). These centrifuges are designed for applications that require moderate centrifugal forces, suitable for separating larger particles or cells. They are commonly used in clinical labs for blood separation, sedimentation of urine samples, and other routine laboratory tasks.

Advantages of Low Speed Centrifuge

- Simplicity and Ease of Use:

Low speed centrifuges are generally straightforward to operate, requiring minimal training for users. Their uncomplicated design makes them accessible for routine laboratory tasks.

- Cost-Effectiveness:

These centrifuges are typically less expensive to purchase compared to high speed models. Maintenance and operational costs are also lower, making them a budget-friendly option for many laboratories.

- Sample Integrity:

The moderate speeds used in low speed centrifuges reduce the risk of damaging delicate samples, such as cells or large biological molecules. This makes them ideal for applications where preserving the integrity of the sample is crucial.

- Versatility in Routine Applications:

Low speed centrifuges are well-suited for common laboratory procedures such as blood separation, sedimentation of urine samples, and other routine sample processing tasks.

- Lower Risk of Heat Generation:

The lower rotational speeds generate less heat, minimizing the risk of heat-induced sample degradation.

Disadvantages of Low Speed Centrifuge

- Limited Speed and RCF:

The lower speed and relative centrifugal force (RCF) limit the range of applications that can be performed with low speed centrifuges.So they are not suitable for separating smaller particles or molecules that require higher centrifugal forces, like viruses, proteins, or subcellular organelles.

- Longer Processing Time:

Due to the lower centrifugal force, low speed centrifuges often require longer run times to achieve the desired separation. This can be a drawback when quick processing is needed.

- Lower Throughput:

They may have limited capacity and throughput, making them less suitable for high-volume processing or large-scale applications.

- Less Advanced Features:

Low speed centrifuges might lack some of the advanced features found in high speed models, such as precise temperature control, advanced rotor options, and more sophisticated programming capabilities.

In summary, while low speed centrifuges offer several advantages such as simplicity, cost-effectiveness, and preserving sample integrity, they also have limitations in terms of speed, range of applications, and throughput. These factors need to be considered when choosing a centrifuge for specific laboratory needs.

High Speed Centrifuge

High speed centrifuges can reach speeds from 10,000 to 30,000 rpm, generating significantly higher centrifugal forces. These centrifuges are designed for more demanding applications, such as isolating smaller particles, pelleting microorganisms, and separating cellular organelles.

Advantages of High Speed Centrifuge

- Higher Speed and RCF (Relative Centrifugal Force):

High speed centrifuges can achieve much higher speeds (10,000 to 30,000 rpm) and greater centrifugal forces compared to low speed centrifuges. This makes them suitable for separating smaller particles, such as subcellular components, proteins, and viruses.

- Versatility:

They can handle a wide range of sample types, including complex mixtures and small particles. Suitable for various applications in molecular biology, biochemistry, and pharmaceutical research.

- Improved Separation Efficiency:

The higher centrifugal force allows for faster and more efficient separation, reducing processing time. This is particularly useful for high-throughput laboratories and time-sensitive applications.

- Advanced Features:

High speed centrifuges often come with sophisticated features like precise temperature control, programmable settings, and multiple rotor options. These features enhance usability and provide greater control over the centrifugation process.

- Enhanced Sample Capacity:

They often have larger rotor capacities, allowing for the processing of more samples in a single run. This increases efficiency and throughput in busy laboratories.

Disadvantages of High Speed Centrifuge

- Higher Cost:

High speed centrifuges are more expensive to purchase due to their advanced capabilities and complex design. Maintenance and operational costs are also higher, which can be a significant investment for some laboratories.

- Complexity:

They require more training to operate safely and effectively. The advanced features and settings can be overwhelming for inexperienced users.

- Potential Sample Damage:

The high centrifugal forces can damage sensitive or fragile samples if not handled properly. Care must be taken to optimize centrifugation conditions to prevent sample degradation.

- Increased Risk of Heat Generation:

High speed operation can generate significant heat, which may affect temperature-sensitive samples. Effective cooling systems are necessary to manage heat generation.

- Safety Considerations:

The high speeds and forces involved pose greater safety risks, requiring stringent safety protocols and equipment handling procedures.

Any imbalance or malfunction can result in severe damage to the centrifuge and potential safety hazards.

In summary, high speed centrifuges offer significant advantages in terms of speed, versatility, and advanced features, making them ideal for complex and high-precision applications. However, they come with higher costs, complexity, and potential risks, which must be carefully managed to ensure safe and effective use.

Comparative Analysis

Here is the comparative analysis of low speed and high speed centrifuges presented in a table sheet:

| Criteria | Low Speed Centrifuge | High Speed Centrifuge |

| Speed and RCF | 300 to 6,000 rpm; moderate centrifugal forces | 10,000 to 30,000 rpm; high centrifugal forces |

| Applications | Blood separation, urine sedimentation, routine lab tasks | Pelleting viruses, separating subcellular components, molecular biology |

| Performance | Suitable for larger particles, longer processing times | Efficient separation of smaller particles, faster processing |

| Cost | Lower purchase and maintenance costs | Higher purchase and maintenance costs |

| Usability | User-friendly, minimal training required | Requires extensive training, more complex operation |

| Sample Integrity | Lower risk of sample damage | Higher risk of sample damage due to high forces |

| Heat Generation | Generates less heat, suitable for heat-sensitive samples | Generates more heat, requires effective cooling systems |

| Advanced Features | Basic features, may lack temperature control and programmability | Advanced features, including precise temperature control and programmability |

| Capacity and Throughput | Limited capacity, lower throughput | Larger capacity, higher throughput |

| Safety Considerations | Lower safety risks, simpler safety protocols | Higher safety risks, stringent safety protocols required |

Choosing between a low speed and high speed centrifuge depends on your specific application needs, budget, and laboratory requirements. Low speed centrifuges are ideal for routine, cost-effective tasks with larger particles, while high speed centrifuges provide the performance and versatility needed for more demanding applications. Here is a guide to help you choosing the right centrifuge:

- Identify Your Application Needs: Determine the types of samples you will be working with and the specific separation tasks required.

- Consider Speed and RCF Requirements: Assess whether your applications require moderate or high centrifugal forces.

- Evaluate Budget Constraints: Consider both the initial purchase cost and ongoing maintenance expenses.

- Assess Throughput Needs: Determine the volume of samples you need to process and choose a centrifuge with appropriate capacity.

- Examine Feature Requirements: Identify any advanced features that may be necessary for your work, such as temperature control or programmable settings.

- Safety and Training: Consider the level of training required and the safety features needed to operate the centrifuge effectively.

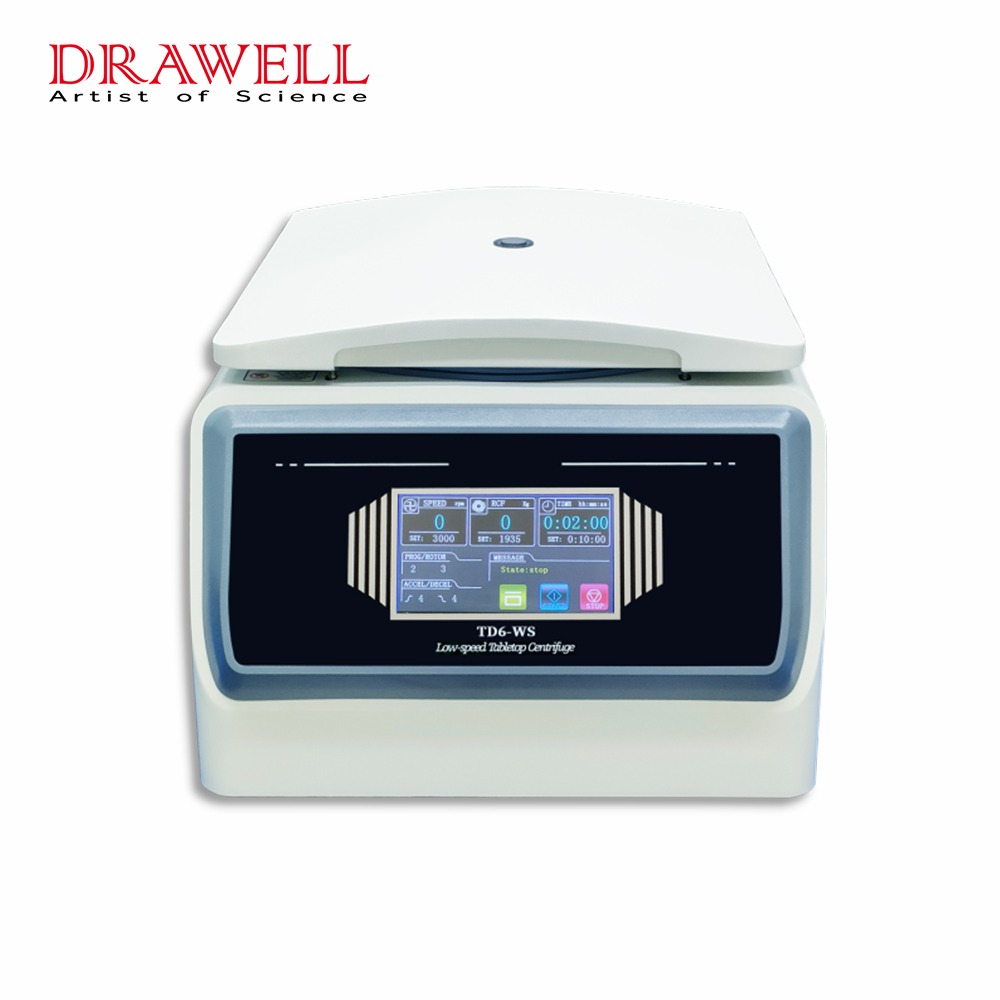

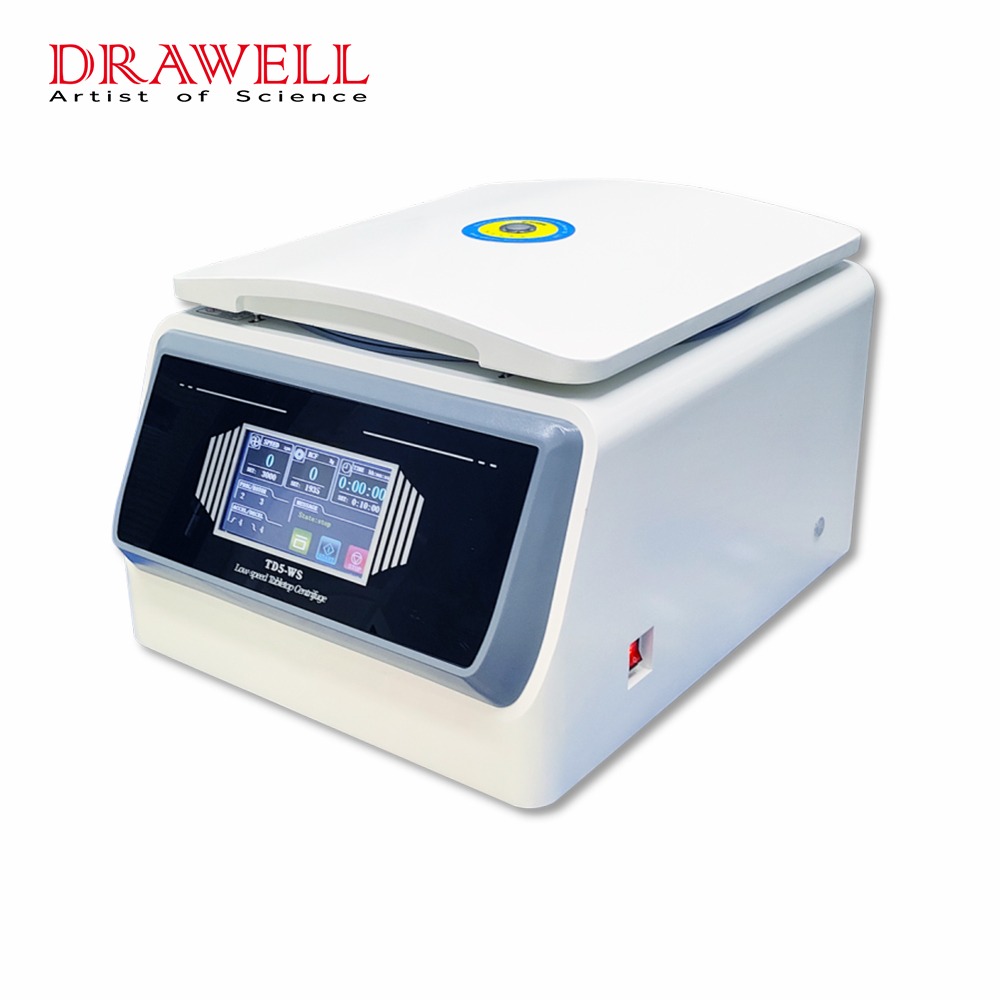

Why Choose Drawell Low Speed and High Speed Centrifuge?

Drawell offers a range of both low speed and high speed centrifuges designed to meet diverse laboratory needs. Here are some reasons to choose Drawell centrifuges:

Quality and Reliability: Drawell centrifuges are built with high-quality materials and advanced technology, ensuring reliable performance and longevity.

Advanced Features: Both low speed and high speed centrifuges from Drawell come with user-friendly interfaces, safety features, and customizable settings to suit various applications.

Comprehensive Support: Drawell provides excellent customer support, including training and maintenance services, ensuring that users can operate their equipment efficiently and safely.

Cost-Effectiveness: While offering advanced features and reliable performance, Drawell centrifuges are competitively priced, providing great value for investment.

In conclusion, selecting the right centrifuge depends on the specific requirements of your applications. Drawell’s range of centrifuges ensures that you can find the perfect fit for your laboratory needs, backed by quality, reliability, and excellent support.