Fourier transform infrared spectrometer (FTIR) is a key tool in the fields of materials science, chemical analysis, etc., which can reveal the molecular structure information of samples through infrared absorption spectra. However, in actual operation, the stability of instrument performance and the quality of the spectrum are highly dependent on the standardization of operation and detailed processing. Here we sorts out the common problems in sample preparation of FTIR spectrophotometer, instrument operation and spectral analysis, and propose targeted solutions and precautions to help experimenters improve test efficiency and result reliability.

Sample Preparation Problems and Precautions

Sample preparation is a basic step in FTIR analysis. The method used depends heavily on the nature of the sample (solid, liquid, gas) and the desired information. Improper handling may lead to spectral distortion or signal loss.

Problems of Different Sample States

Solid Samples

- Insufficient Grinding: Poorly ground samples can result in uneven distribution and weak spectral signals. It’s better to use a mortar and pestle or mechanical grinder to achieve fine and uniform particles.

- Uneven Pressing in KBr Pellets: Uneven distribution of the sample in the KBr pellet may cause light scattering and spectral artifacts. Please ensure thorough mixing of the sample with KBr and use consistent pressure when pressing pellets.

- Hygroscopic KBr: KBr can absorb moisture from the environment, leading to spectral interference. Please store KBr in a desiccator and handle it in a low-humidity environment.

Liquid Samples

- Inappropriate Cell Thickness: Improper path length can result in overly strong or weak absorption bands. Please select the correct spacer to achieve an optimal path length for your liquid sample.

- Sample Volatility: Volatile samples may evaporate during measurements, altering concentration and spectra. Please use sealed cells or rapid data collection methods to minimize evaporation effects.

Gaseous Samples

- Poorly Sealed Gas Cells: Leaks in the gas cell can lead to contamination and incorrect results. Please regularly check and maintain seals to ensure airtight conditions.

- Low Sample Concentration: Insufficient gas concentration can cause weak absorption signals. Please increase sample pressure in the cell or use a gas cell with a longer path length.

Background Interference

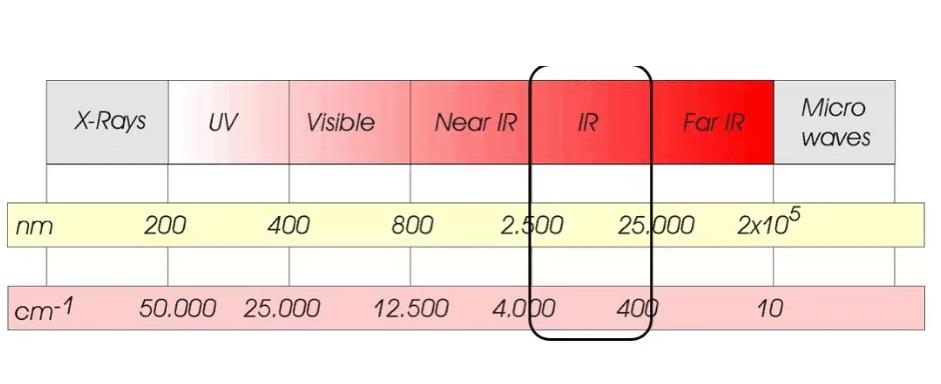

Water Vapor and Carbon Dioxide Peaks

Water vapor and CO₂ in the atmosphere can introduce absorption peaks near 3400 cm⁻¹ and 2300 cm⁻¹, respectively. Please purge the instrument with dry air or inert gas to minimize interference.

Solvent Residue and Sample Contamination

Residual solvents or contaminated samples can obscure the true spectral features. Please ensure thorough drying and cleaning of samples and equipment prior to measurement.

Precautions

- Sample Quantity: Use an appropriate sample quantity based on the selected measurement technique. Insufficient sample amounts may result in weak signals, while excessive amounts can cause scattering.

- Sample-to-KBr Ratio: Usually, the ratio of sample to KBr is 1:100, which can be adjusted according to actual conditions. Incorrect proportions of sample and KBr can lead to uneven pellet distribution and spectral artifacts.

- Sample Preparation Environment: Work in a clean, low-humidity environment and handle samples with care to avoid contamination. High humidity or particulate contamination can degrade sample quality.

- Prevent cross contamination: Clean molds, mortars, and slides thoroughly after each sample preparation.

By addressing these aspects of sample preparation, users can significantly improve the quality and reliability of their FTIR measurements.

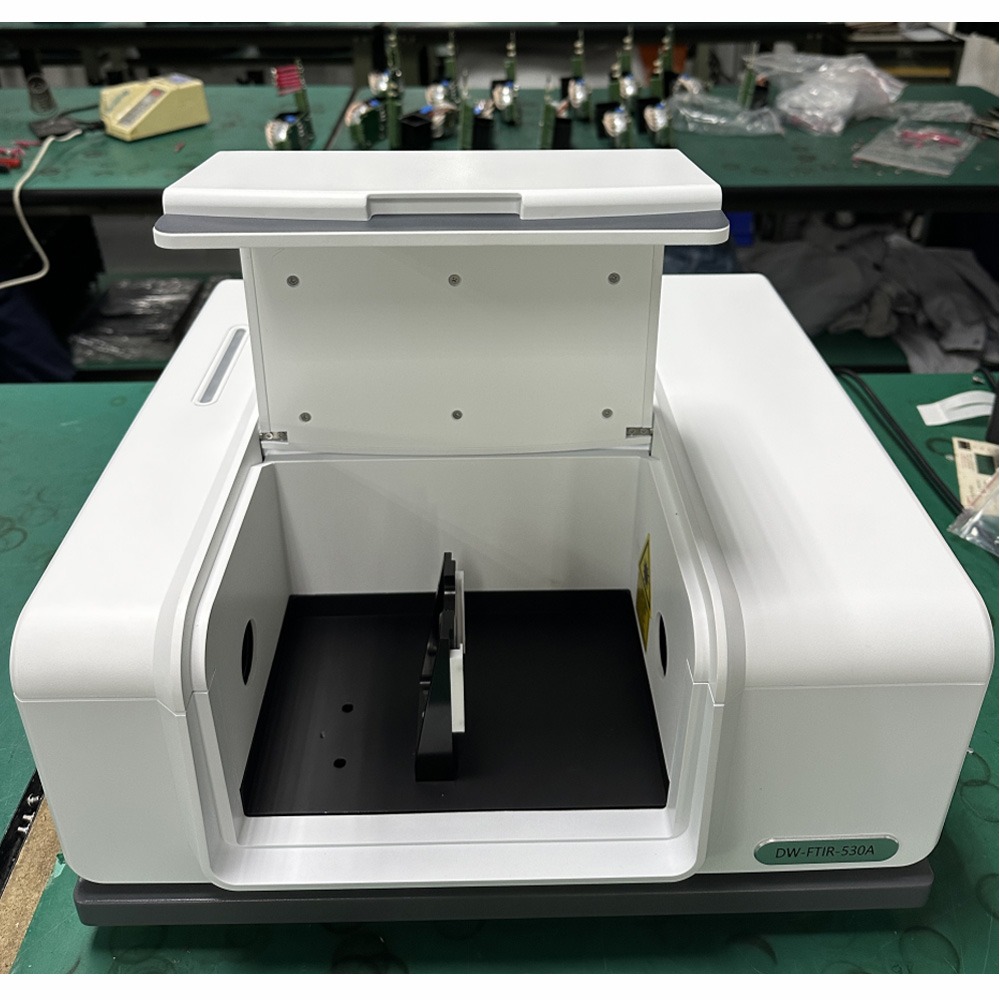

Improper FTIR instrument operation may cause baseline drift, signal-to-noise ratio degradation, and even damage to optical components. Mastering standard procedures and understanding the principles of the instrument are key to avoiding failures.

Common Problems and Solutions:

Laser instability: Fluctuations in the laser can affect the accuracy of the measurements. Allow the instrument to warm up sufficiently before use. If the problem persists, consult the instrument manual or contact service personnel.

Detector saturation: An overly strong signal can saturate the detector, leading to distorted spectra. Adjust the instrument parameters (e.g., gain, aperture) to reduce the signal intensity.

Interferometer misalignment: Misalignment of the interferometer mirrors can degrade the spectral resolution. Regular maintenance is essential.

Background changes: Variations in the background spectrum (due to changes in humidity, temperature, or instrument conditions) can affect the baseline of the sample spectrum. Please run background spectra frequently, especially when environmental conditions change.

Precautions:

- Follow the manufacturer’s recommended operating procedures.

- Allow the instrument to warm up before use.

- Regularly calibrate the instrument.

- Maintain a clean and stable environment around the instrument.

- Keep the instrument software up to date.

The stability of instrument operation depends on environmental control and regular maintenance. It must be performed strictly in accordance with the manual procedures to avoid hardware damage or data abnormalities due to misoperation.

Spectrum Analysis Problems and Precautions

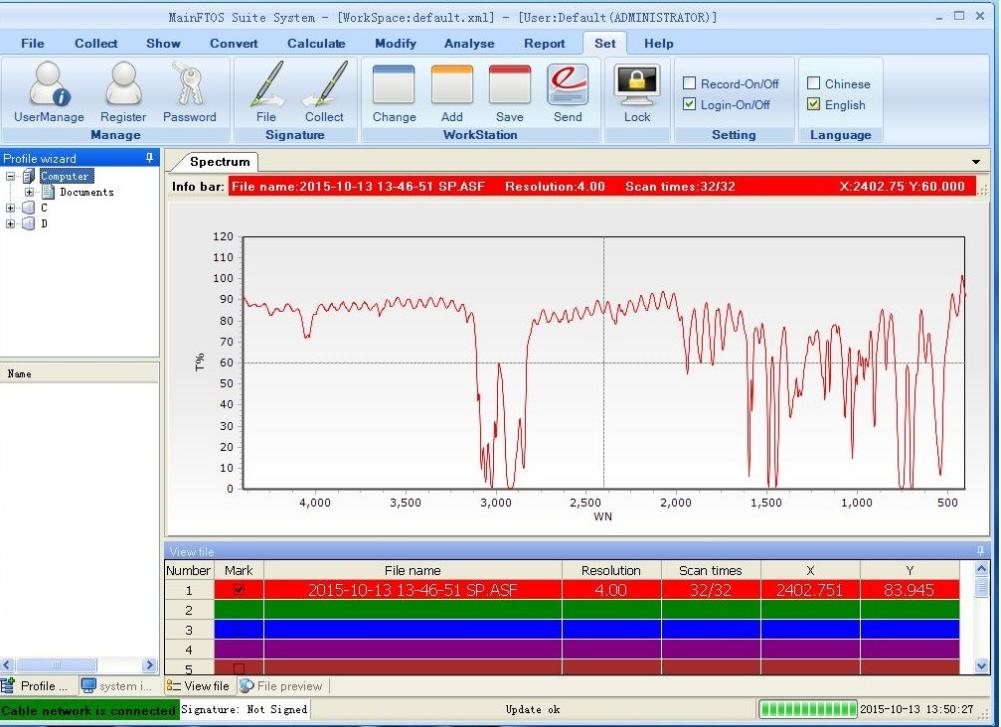

Spectral analysis is the core of FTIR analysis, but peak shift, uneven baseline or abnormal peaks may mislead the conclusion. A comprehensive judgment based on the instrument status and sample properties is required.

Common Problems and Solutions:

Overlapping bands: Closely spaced bands can be difficult to distinguish, especially in complex molecules. You can use spectral deconvolution techniques or consult spectral libraries for assistance. Consider using higher resolution if possible.

Noise: Random noise can obscure weak signals. You can improve the signal-to-noise ratio by increasing the number of scans or optimizing instrument parameters.

Baseline distortion: An uneven baseline can affect the apparent intensities and positions of peaks. Please use baseline correction algorithms to flatten the baseline.

Incorrect peak assignment: Misidentification of peaks can lead to incorrect conclusions about the sample’s composition. Solution: Consult spectral databases, textbooks, and published literature for accurate peak assignments.

Precautions:

- Be familiar with the characteristic absorption bands of common functional groups.

- Use spectral databases and libraries to aid in peak identification.

- Compare the spectrum with reference spectra.

- Consider the chemical context of the sample when interpreting the spectrum.

- Be aware of potential interferences and artifacts.

Some Abnormal Spectral Bands:

Water vapor bands: These appear as sharp peaks in the regions around 3700-3500 cm⁻¹ and 1650 cm⁻¹.

Carbon dioxide bands: These are seen as sharp peaks around 2360-2330 cm⁻¹ and a doublet around 667 cm⁻¹.

Combination bands and overtones: These weaker bands can appear in addition to the fundamental vibrations and can sometimes be mistaken for impurities.

Spectral analysis needs to take into account both instrument calibration and data processing techniques, and the identification of abnormal peaks requires traceability analysis combined with the entire experimental process.

Summary

FTIR analysis is a technology that is highly dependent on operational details, and requires strict control from sample preparation to spectral analysis. Experimenters need to have a deep understanding of the instrument principles, establish standardized operating procedures, and ensure data reliability through regular maintenance and calibration. In the future, with the application of intelligent diagnostic algorithms and high-sensitivity detectors, the automation and accuracy of FTIR will be further improved, but the core position of operational specifications will always be irreplaceable.