Selecting the right metal alloy analyzer is crucial for industries that rely on precise material identification and composition analysis. Whether in manufacturing, aerospace, construction, or recycling, the right analyzer ensures quality control, regulatory compliance, and optimal performance of metal components. This article delves into the essential factors to consider when choosing a metal alloy analyzer, exploring different types of analyzers, and compare their pros and cons. Additionally, we’ll recommened you a trusted metal alloy analyzer supplier.

Understanding Your Metal Analysis Needs

Before diving into the different types of metal alloy analyzers, it’s essential to clearly define your needs. Various factors influence the choice of an analyzer, including the type of metals you work with, the required accuracy and precision, the working environment, and budget constraints, etc.

- Type of Metals: Determine the types of metal alloys you will be analyzing (e.g., ferrous, non-ferrous, precious metals) and their physical forms (e.g., solid, liquid, powder). The type of metal largely dictates the type of analyzer you will need.

- Accuracy and Precision: Determine the level of accuracy and precision required. High-precision industries like aerospace may require more advanced analyzers compared to general manufacturing.

- Throughput: Consider the number of samples you need to analyze per day or hour.

- Working Environment: Consider whether the analyzer will be used in a lab setting or in the field. Portable analyzers are essential for on-site analysis. A benchtop model is often used in laboratory.

- Budget Constraints: Balancing cost with features is critical. High-end analyzers come with advanced features but at a higher price.

Clearly defining your requirements will streamline the selection process, ensuring you choose an analyzer that meets your specific needs and provides the best return on investment.

Types of Metal Alloy Analyzers

Metal alloy analyzers come in various forms, each with its own advantages and suitable applications. Understanding the different types can help you choose the one that aligns best with your operational requirements.

Based on Technology

X-Ray Fluorescence (XRF) Analyzers

X-Ray Fluorescence (XRF) analyzers use X-rays to excite the atoms in a metal sample. When these atoms return to their normal state, they emit secondary X-rays at characteristic energies, allowing for the identification and quantification of the elements present in the sample. It can be divided into:

Handheld XRF Analyzers: Portable devices used for on-site analysis.

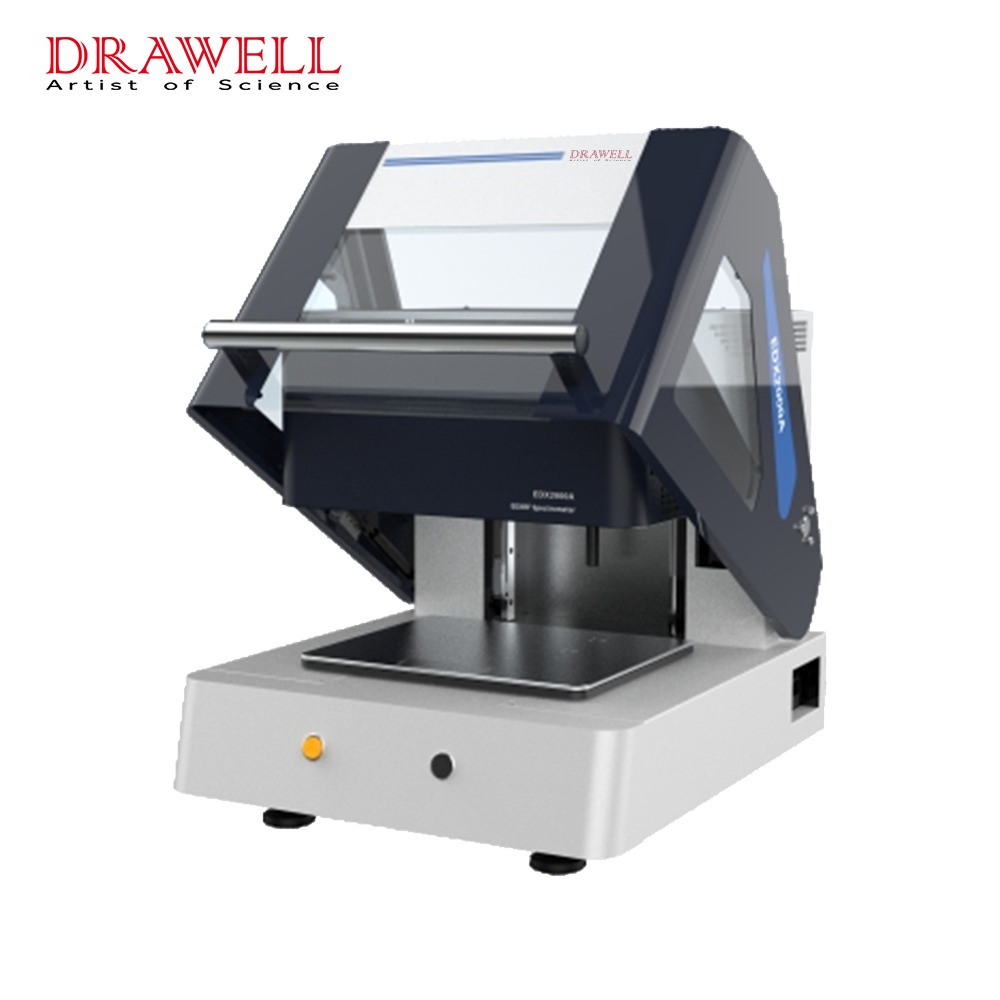

Benchtop XRF Analyzers: Larger, more robust units used in laboratory settings.

Advantages:

- Non-Destructive: Does not alter or damage the sample.

- Quick Results: Provides rapid analysis, often within seconds.

- Versatile: Suitable for a wide range of metals and alloys.

- Portable Options: Handheld models are available for field use.

- Minimal Sample Preparation: Requires little to no sample preparation.

Optical Emission Spectroscopy (OES) Analyzers

Optical Emission Spectroscopy (OES) analyzers use a spark or arc to excite the atoms in a metal sample, causing them to emit light at specific wavelengths. These wavelengths are characteristic of the elements present, allowing for their identification and quantification. It can be divided into:

Arc/Spark OES Analyzers: Use an electric arc or spark to excite the sample.

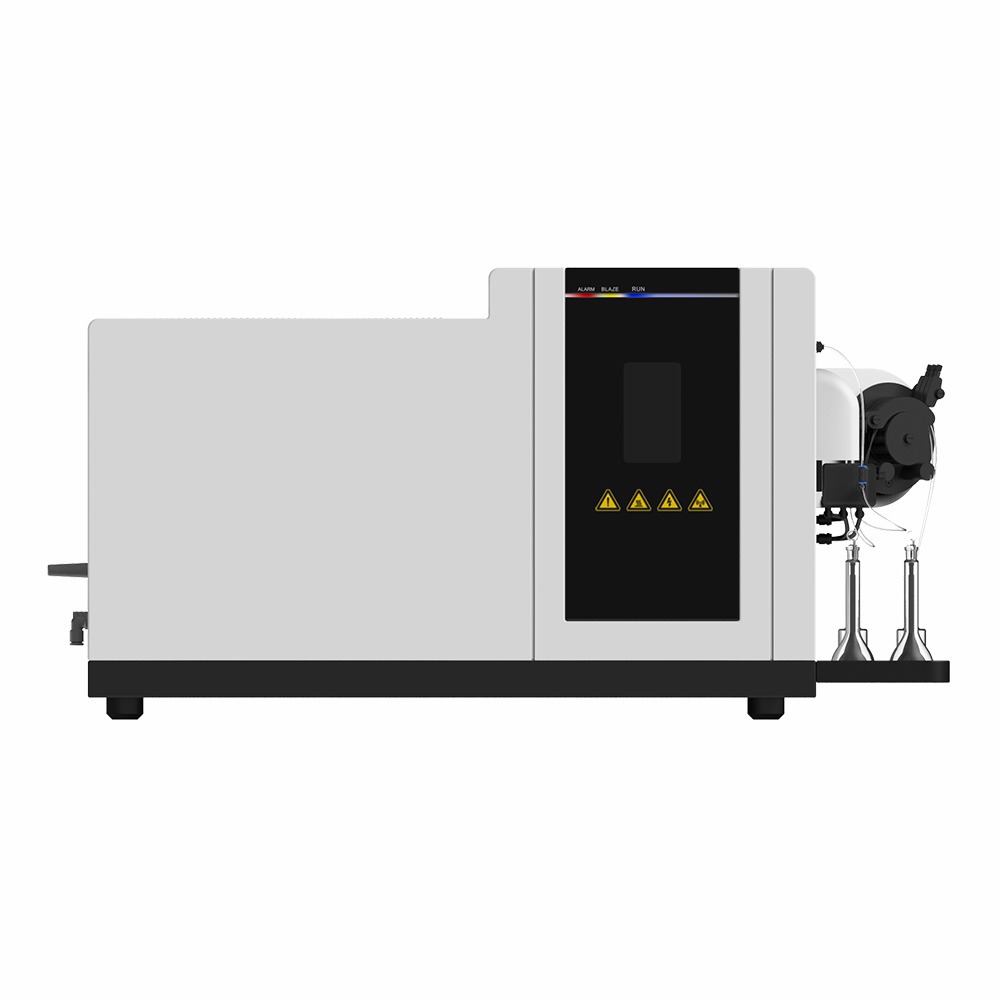

ICP-OES Analyzers: Utilize an inductively coupled plasma source for excitation.

Advantages:

- High Accuracy: Provides highly accurate and precise results.

- Multi-Element Detection: Can analyze multiple elements simultaneously.

- Suitable for Bulk Analysis: Effective for analyzing large volumes of material.

- Wide Elemental Range: Capable of detecting a broad range of elements.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

ICP-MS analyzers use an inductively coupled plasma to ionize the sample. The ions are then separated and quantified based on their mass-to-charge ratio using a mass spectrometer.

Advantages:

- Ultra-High Sensitivity: Can detect trace and ultra-trace elements.

- Isotopic Analysis: Capable of performing isotopic analysis.

- Multi-Element Detection: Analyzes multiple elements simultaneously.

- Wide Elemental Range: Effective for a broad range of elements.

- Low Detection Limits: Ideal for detecting very low concentrations of elements.

Based on Usage Environment

Portable Analyzers

Portable analyzers are compact, lightweight devices designed for on-site and field use. They are ideal for situations where mobility and rapid analysis are essential. The portable XRF analyzers are the representative type.

Advantages:

- Mobility: Easily transported to different locations.

- Rapid Results: Provides quick analysis, often within seconds.

- User-Friendly: Typically designed for easy operation in the field.

- Versatile: Suitable for various applications, including scrap metal sorting, mining, and environmental testing.

- Minimal Sample Preparation: Often requires little to no sample preparation.

Benchtop Analyzers

Benchtop analyzers are larger, more robust devices designed for use in laboratories or controlled environments. They offer high precision and accuracy, making them ideal for detailed analysis.

Advantages:

- High Precision and Accuracy: Provides detailed and accurate results.

- Stable Environment: Operates in a controlled environment, reducing external interference.

- Advanced Features: Often equipped with more advanced features and capabilities.

- Suitable for Complex Analysis: Ideal for in-depth and complex analytical needs.

- High Throughput: Capable of processing a large number of samples efficiently.

Choosing the right metal alloy analyzer involves understanding the different technologies and their applications. XRF, OES, ICP-OES, and ICP-MS analyzers each offer unique advantages for specific needs.

Comparing Different Analyzers

Here is the comparison of different analyzers:

| Criteria | XRF Analyzers | OES Analyzers | ICP-OES Analyzers | ICP-MS Analyzers |

| Portability | Handheld and benchtop models available | Typically benchtop, some portable options | Primarily benchtop | Primarily benchtop |

| Accuracy and Precision | Moderate to high | High | Very high | Ultra-high |

| Sensitivity | Moderate | High | Very high | Ultra-high |

| Sample Preparation | Minimal to none | Requires sample preparation | Requires sample preparation | Requires sample preparation |

| Speed of Analysis | Rapid (seconds) | Moderate (minutes) | Moderate to fast | Fast to moderate |

| Non-Destructive | Yes | No | No | No |

| Elemental Range | Broad range, but surface-focused | Very broad, including bulk analysis | Very broad | Very broad |

| Multi-Element Analysis | Yes | Yes | Yes | Yes |

| Field Use | Suitable (handheld models) | Limited (portable models) | Not suitable | Not suitable |

| Applications | General metal analysis, recycling, manufacturing | Metallurgy, manufacturing, high-precision applications | High-precision applications, research | Trace element analysis, research, high-tech applications |

| Cost | Moderate to high | High | High to very high | Very high |

| Advantages | Non-destructive, quick results, minimal prep | High accuracy, multi-element, bulk analysis | High sensitivity, wide dynamic range, multi-element | Ultra-high sensitivity, isotopic analysis, low detection limits |

| Disadvantages | Surface analysis only, high initial cost | Destructive testing, sample preparation needed | Destructive testing, sample preparation needed | Destructive testing, sample preparation needed |

By carefully comparing different analyzers based on your specific needs, you can identify the most suitable option for your application.

Get Metal Alloy Analyzer from Drawell

When it comes to sourcing reliable and high-quality metal alloy analyzers, Drawell stands out as a trusted supplier. Drawell offers a range of advanced analyzers tailored to various industry needs, ensuring you get accurate and reliable results every time.

Why Choose Drawell?

- Wide Range of Products: Drawell provides a comprehensive selection of XRF, OES, ICP-OES and ICP-MS analyzers, catering to diverse analytical requirements.

- Advanced Technology: Their analyzers incorporate the latest technological advancements for precise and rapid analysis.

- Customer Support: Drawell offers excellent customer service, including training, technical support, and maintenance.

- Cost-Effective Solutions: They provide competitive pricing without compromising on quality and performance.

Choosing the right metal alloy analyzer is crucial for ensuring the quality and integrity of your metal products. With Drawell, you can be confident in the accuracy, reliability, and efficiency of your metal analysis, backed by a trusted supplier committed to your success.