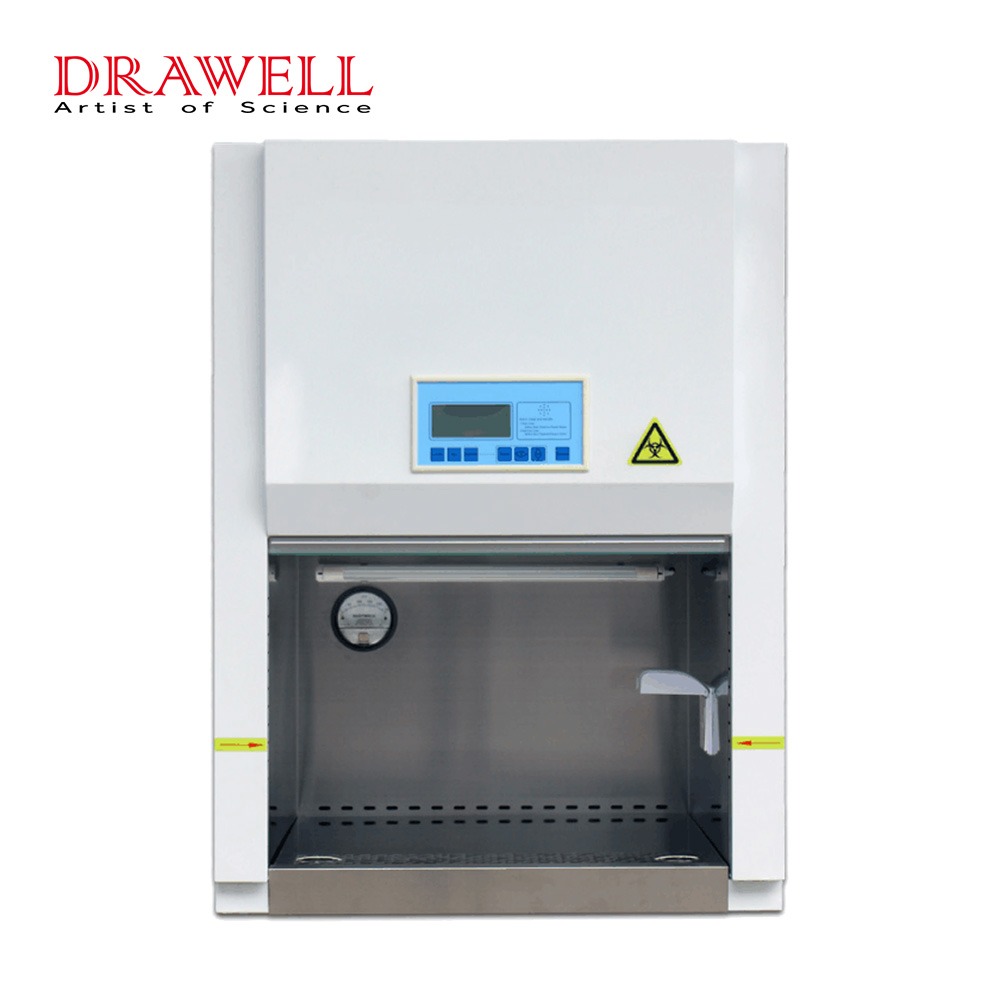

Biosafety Cabinet

The biosafety cabinet provided by Drawell is designed to offer a controlled environment for safe handling of sensitive biological materials. These cabinets protect operators, products, and the surrounding environment from contamination by ensuring the workspace is free of harmful particles. Equipped with HEPA filtration systems, they effectively prevent airborne particles and pathogens from escaping, ensuring compliance with biosafety standards. With ergonomic design, advanced airflow technology, and user-friendly controls, Drawell biosafety cabinets are ideal for laboratories handling biological research, diagnostics, and pharmaceutical applications.

Features of the Biosafety Cabinet

- 10°tilt design, more ergonomic.

- Vertical flow negative pressure machine type, A2: 30% of air is filtered and recycled, 70% of air is filtered and then discharged into the room or connected to the exhaust system. B2: 100% air is filtered and then discharged into the room or connected to the exhaust system.

- Lighting and sterilization system safety interlock.

- HEPA high-efficiency filter can filter more than 99.99% of 0.3um dust particles.

- Digital display LCD control interface, fast, medium. Slow three-speed.

- The working area is SUS304 brushed stainless steel, strong, durable, easy to clean, and anti-corrosion.

- Standard configuration diameter 160mm, 1-meter long exhaust duct and elbow.

- The work area is equipped with a five-hole socket.

Classification of Biosafety Cabinet

All Steel Class II A2 Biological Safety Cabinet

• Working area size: 1040*650*620/1340*650*620/1640*650*620mm

• Fluorescent/UV lamp: 12W×②/20W×①; 20W×②/30W×①; 20W×②/30W×①

All Steel Class II B2 Biological Safety Cabinet

• Working area size: 1040*650*620/1340*650*620/1640*650*620mm

• Fluorescent/UV lamp: 12W×②/20W×①; 30W×②/30W×①; 30W×②/30W×①

Class II A2 Biological Safety Cabinet

• Working area size: 1000*650*620/1300*650*620/1600*650*620mm

• Fluorescent/UV lamp: 20W*1PC/20W*1PC; 30W*2PC/30W*1PC; 30W*2PC/30W*2PC.

Class II B2 Biological Safety Cabinet

• Working area size: 1000*650*620/1300*650*620/1600*650*620mm

Desktop Bio-safety Cabinet BSC-700IIA2-EP

• Filtration Level/Filtration Efficiency: ≥99.995%, @0.3μm

• Working area size: 600×500×520mm

• LED/UV lamp: 8W×① / 20W×①

Types of Biosafety Cabinet

Bio-safety Cabinets are divided into three categories: Class I, II, and III according to their protection capabilities and design differences. The following are their core differences:

1. Class I Biological Safety Cabinets

Features:

- The front is open, and the operator conducts experiments through the opening. Negative pressure is maintained inside to prevent aerosol leakage.

- Exhaust air is only filtered through HEPA, and unfiltered airflow directly enters the work area.

Object of protection:

Protect the operator and the environment, but not the experimental samples (which may be contaminated). For this reason, this type of biological safety cabinet is rarely used in laboratories.

Airflow pattern:

Inlet airflow (unfiltered) → work area → Exhaust air is filtered by HEPA and then discharged (can be circulated indoors or discharged outdoors).

2. Class II Biological Safety Cabinets

Features:

The front is open, but a barrier is formed by vertical laminar HEPA filtered airflow (30% external exhaust, 70% circulation).

It is divided into subcategories: A1, A2, B1, B2, and the difference lies in the airflow ratio and exhaust method.

Protection object:

It protects the operator, sample and environment at the same time (triple protection), which is also the most widely used biological safety cabinet at present.

Application:

It is suitable for BSL-2 and BSL-3 pathogens (such as hepatitis virus and tuberculosis).

Type B needs to be exhausted (suitable for volatile toxic chemicals), and type A can be circulated internally.

Airflow mode:

Inlet airflow (entering the working area after HEPA filtration) → downward laminar flow to protect the sample → exhaust air secondary filtration (partial external exhaust).

3. Class III biological safety cabinet

Features:

- Completely enclosed, operation is performed through gloves, and there is no direct opening.

- Both the inlet and exhaust air are double HEPA filtered (or combined with incineration).

Protection object:

The highest level of protection, comprehensive protection of personnel, samples and environment.

Application:

Handling high-risk pathogens (BSL-4, such as Ebola virus, smallpox virus).

Need to be linked with the laboratory negative pressure system and independently supply oxygen.

Airflow mode:

Fully enclosed negative pressure → All gases are forced to be discharged after HEPA filtration, without circulation.

The Differences Between Type A1 A2 B1 and B2 Biosafety Cabinet

Type A1

Features:

- 30% of the air is exhausted, and 70% of the air is recycled after HEPA filtration.

- No external exhaust duct is required, relying on internal ventilation in the laboratory.

- The air flow rate of the front window is low (about 0.38-0.51 m/s).

Application: Ordinary microbiological experiments without volatile/low-toxic chemicals (such as cell culture, BSL-1/2 pathogen operations).

Type A2 (upgraded version of Type A1)

Features:

- The air flow rate of the front window is higher (≥0.51 m/s), and the safety is improved.

- Some models support full exhaust mode (such as when handling a small amount of volatile reagents).

- Still mainly circulating (70% circulation, 30% exhaust).

Application:

- Experiments with trace volatile reagents (such as a small amount of ethanol and formaldehyde), but still need to be cautious.

- Conventional molecular biology experiments, clinical tests, etc.

Type B1

Features:

- 70% external exhaust, 30% air circulation (only the downdraft part is circulated).

- External exhaust duct is required to force the contaminated air to be exhausted.

- Better protection against chemical reagents and radioactive materials than Type A.

Application:

- Experiments containing a small amount of volatile toxic reagents (such as benzene and chloroform).

- Low-dose radioisotope operations (such as labeling experiments).

Type B2

Features:

- 100% external exhaust, no air circulation.

- All airflows (inlet, downdraft, exhaust) are discharged after HEPA filtration.

- The highest safety, but high energy consumption and requires the support of a strong laboratory exhaust system.

Application:

- Operation of highly volatile/highly toxic chemicals (such as strong acids and carcinogens).

- High-risk radioactive experiments or pathogen research at Bio-safety Level 3 (BSL-3).

Biosafety Cabinet Application

The Drawell’s primary purpose of a biosafety cabinet is to protect the operator and the surrounding environment from biological contaminants and other hazardous materials. There are various classes of biological safety cabinets, each defined by the required level of biosafety and containment as well as the required configuration of the cabinetry. The proper class and type is selected in accordance with the requirements for the specific application and level of bio-containment needed. It is widely used in scientific research, teaching, clinical testing and production in the fields of microbiology, biomedicine, genetic engineering, biological products, etc. It is the most basic safety protection equipment in the first-level protective barrier in laboratory biosafety.

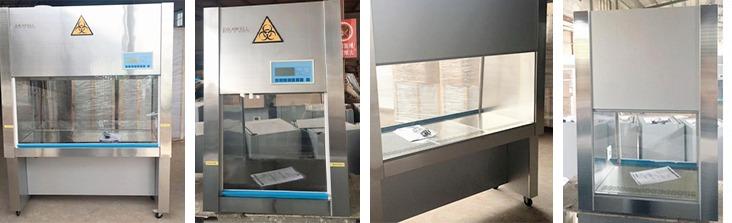

Biosafety Cabinet Display

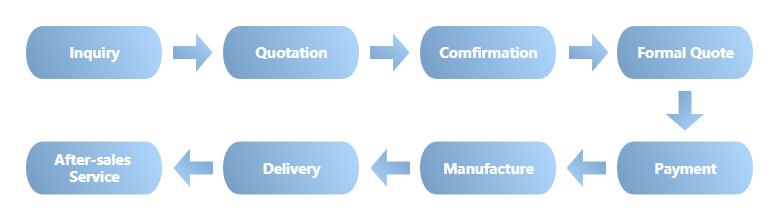

Why Choose Us?

Drawell as the top five instrument export trader in China, our products are highly sought after by customers in America, South America, Asia, and Africa.

The drawell’s complete machine warranty is 12 months, and we provide lifetime technical service support.

During the warranty period, if the product has quality problems under normal use, after verification by Party B, free maintenance services will be provided without charging any fees to Party A; if the quality problem is not the problem of the instrument itself, it is caused by the user’s human factors. Party B shall charge for the repair or replacement of parts.

Response time: within 24 hours. Any problem, our professional team can check for you remotely.