Accurate density measurements are critical in various fields such as chemistry, material science, quality control, and manufacturing. To ensure the precision and reliability of these measurements, proper calibration and standardization practices must be adhered to. This article explores the essential practices for calibrating and standardizing density balances, ensuring the highest standards of measurement are met.

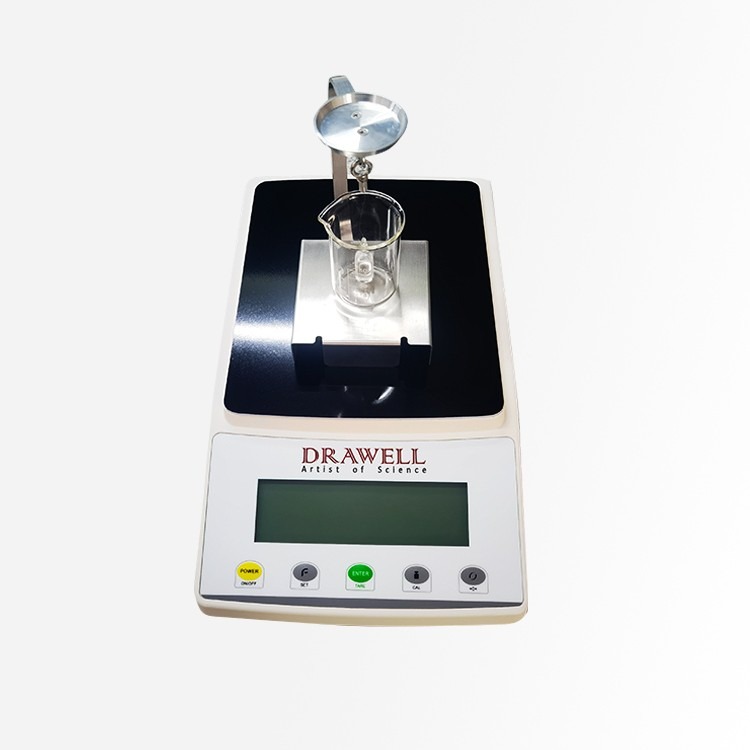

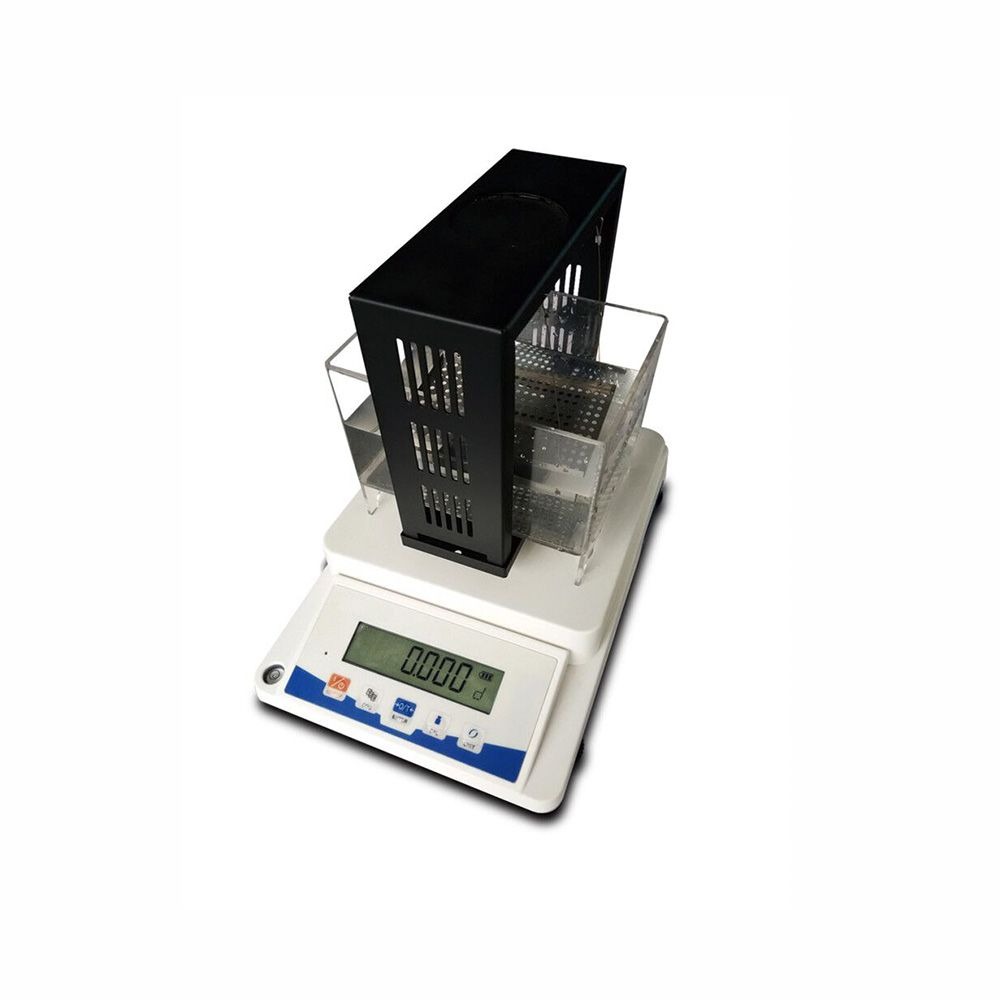

Understanding Density Balances

This chart provides a concise overview of the essential aspects of understanding a density balance

| Aspect | Description |

| Definition | An instrument used to measure the density of a sample by determining its mass and volume. |

| Purpose | Provides accurate measurements of density, critical for scientific research, quality control, and industrial processes. |

| Measurement Formula | Density = Mass / Volume (expressed in units such as g/cm³ or kg/m³). |

| Applications | ChemistryMaterials ScienceQuality ControlManufacturing |

| Components | Weighing Mechanism: Measures the mass of the sampleVolume Determination: Measures the volume of the sample (often using displacement or geometrical calculations) |

| Types of Samples | SolidsLiquidsGases (with specialized equipment) |

| Factors Affecting Accuracy | TemperatureHumidityAir Pressure |

| Key Features | High Precision WeighingVolume Measurement CapabilityDigital DisplayCalibration Functionality |

Importance of Calibration and Standardization in Density Balances

1. Accuracy of Measurements

- Precision and Reliability: Calibration ensures that the density balance provides precise and reliable measurements by comparing the balance’s readings with known standards. Accurate measurements are crucial for research validity and product quality.

- Error Minimization: Regular calibration helps identify and correct systematic errors, minimizing measurement inaccuracies caused by instrument drift, environmental changes, or wear and tear.

2. Consistency and Comparability

- Standardization: Ensures that measurements are consistent over time and across different instruments. This consistency is vital for comparing results from different batches, locations, or periods.

- Uniform Procedures: Following standardized procedures allows different operators and laboratories to produce comparable results, which is essential for collaborative research and quality assurance in manufacturing.

3. Compliance with Standards and Regulations

- Regulatory Requirements: Many industries are subject to strict regulatory standards that mandate regular calibration and standardization of measurement instruments. Compliance ensures that products meet safety, quality, and performance standards.

- Audit Readiness: Proper documentation of calibration and standardization practices ensures that an organization is prepared for audits by regulatory bodies or customers.

4. Quality Control and Assurance

- Product Consistency: In manufacturing, accurate density measurements are crucial for maintaining the consistency and quality of products, such as pharmaceuticals, chemicals, and food products.

- Process Control: Regular calibration and standardization help in monitoring and controlling production processes, leading to reduced variability and improved process efficiency.

- Cost Efficiency

- Reduced Waste: Accurate density measurements help in optimizing material usage, reducing waste, and saving costs. Incorrect measurements can lead to product recalls, rework, and financial losses.

- Extended Equipment Life: Regular maintenance and calibration can extend the life of the density balance by ensuring it operates within its optimal performance range.

6. Scientific Integrity

- Research Validity: In scientific research, accurate measurements are essential for the validity and reproducibility of experimental results. Calibration and standardization are fundamental to maintaining the integrity of scientific data.

- Publication Standards: Many scientific journals and funding agencies require detailed documentation of measurement accuracy and standardization procedures to ensure the credibility of published research.

7. Troubleshooting and Problem Solving

- Identifying Issues: Regular calibration helps identify potential issues with the density balance early, allowing for timely troubleshooting and repairs.

- Continuous Improvement: Monitoring calibration data over time can provide insights into instrument performance, leading to continuous improvement in measurement practices.

8. Trust and Credibility

- Customer Confidence: Consistently accurate and reliable measurements build trust with customers, stakeholders, and regulatory bodies. This credibility is crucial for maintaining a positive reputation and competitive advantage.

- Data Integrity: Ensures that the data generated is trustworthy, which is essential for decision-making processes in research, quality control, and production management.

Calibration and Standardization Practices in Density Balance

Calibration of a density balance is crucial for ensuring accurate and reliable measurements of the density of various materials.

1. Initial Setup and Environmental Considerations

- Placement: Ensure the density balance is placed on a stable, vibration-free surface.

- Environmental Conditions: Control the temperature, humidity, and air currents in the laboratory as these can affect measurements. The instrument should be at thermal equilibrium with the room.

- Cleaning: Clean the instrument and any containers used in the measurements to avoid contamination and ensure accuracy.

2. Calibration Procedure

- Zero Calibration (Tare): Before starting any measurements, the balance should be zeroed to eliminate the weight of any container used.

- Internal Calibration: Many modern density balances have an internal calibration function. This should be used according to the manufacturer’s instructions.

- External Calibration: If external calibration is required, use calibrated weights that conform to the balance’s specifications.

3. Standard Solutions and Calibration Materials

- Reference Standards: Use reference standards of known density, typically distilled water and certified calibration weights, to calibrate the density balance.

- Water: Distilled or deionized water at a known temperature is often used because its density is well-documented.

- Certified Density Standards: Use certified liquids or solid materials with known densities for calibration.

- Temperature Control: Measure the temperature of the calibration standard as density varies with temperature. Use a thermometer with a known accuracy.

4. Calibration Steps

- Prepare the Standard: Pour distilled water or another standard liquid into the measuring container.

- Temperature Equilibrium: Allow the liquid to reach room temperature and measure the temperature accurately.

- Measure Density: Place the container in the balance and measure the density.

- Adjust Calibration: Compare the measured density to the known value at the measured temperature. Adjust the calibration settings of the balance if necessary.

- Repeat for Accuracy: Perform the calibration procedure multiple times to ensure consistency and accuracy.

5. Regular Calibration and Maintenance

- Daily Checks: Perform a quick calibration check at the start of each day or shift.

- Periodic Calibration: Conduct a more thorough calibration at regular intervals, as recommended by the manufacturer or based on the frequency of use.

- Service and Maintenance: Schedule regular maintenance and servicing by qualified personnel to keep the balance in optimal condition.

6. Documentation

- Record Keeping: Document all calibration activities, including date, time, standards used, environmental conditions, and any adjustments made.

- Calibration Certificates: Maintain certificates for the reference standards and calibration weights used.

7. Troubleshooting

- Consistency Checks: Regularly check the consistency of measurements using different standards.

- Error Identification: Identify and correct any deviations or errors promptly. Common issues include air bubbles in liquids, contamination, or environmental fluctuations.

8. Advanced Techniques

- Automation: Some advanced density balances allow for automated calibration and measurement, improving accuracy and reducing user error.

- Software Integration: Use software provided by the manufacturer for data analysis and calibration tracking.

Conclusion

Calibration and standardization are critical practices for ensuring the accuracy and reliability of density balances. By adhering to best practices, laboratories can maintain high standards of measurement, ensuring that the data obtained is accurate and reliable.