Laboratory basic equipment is the first equipment for scientific research and clinical medicine, but many laboratories often focus on analytical clinical tests and ignore basic equipment.

The laboratory centrifuge is one of the basic equipment of the laboratory. It is widely used in hospital laboratories. A centrifuge is an indispensable tool for separating serum, precipitating tangible cells, concentrating bacteria, and PCR tests.

How Does a Laboratory Centrifuge Work?

During the high-speed rotation of the laboratory centrifuge, the movement caused by the centrifugal force causes the solid matter suspended in the liquid to form a sediment, that is, the mass or volume of the object in the suspended liquid moves in the direction of the largest radius of the rotor, while the mass or Smaller volumes are deposited at closer rotor radii.

We mentioned the concept of centrifugal force above. A centrifuge is a machine that generates centrifugal force. The centrifugal force is related to the rotor radius, rotational speed, and sample quality: F=Rmω2F: centrifugal force: R: radius: m: sample quality: to rotational speed, centrifugal force is one of the most important parameters to measure the laboratory centrifuge. First, it is also one of the different standards of the centrifuge grade. The laboratory centrifuge will give the maximum centrifugal force of the centrifuge when it leaves the factory.

We all know that the radius of the rotor and the quality of the sample are constant during operation, only the speed can be changed through control, so we are often used to describe a centrifuge by the speed. Such as high-speed centrifuges, and ultra-high-speed centrifuges.

Classification and the Basic Structure of Centrifuge

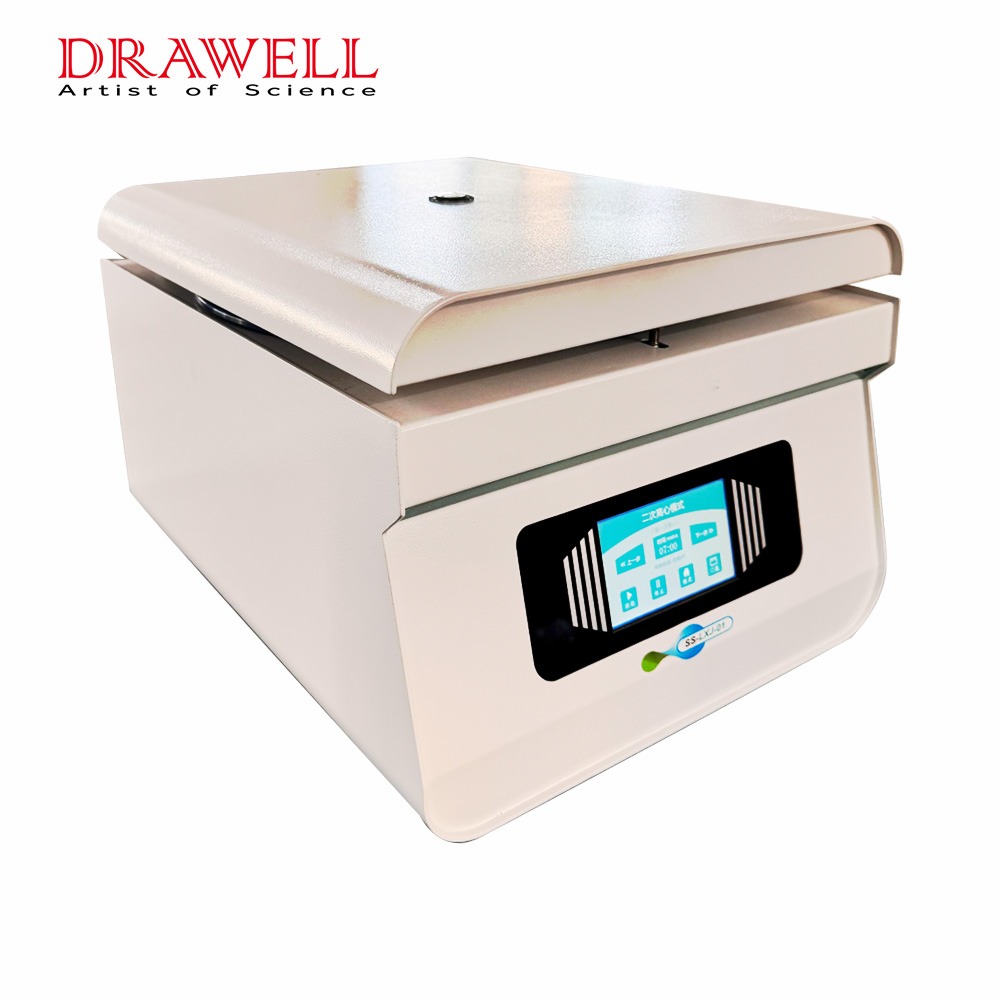

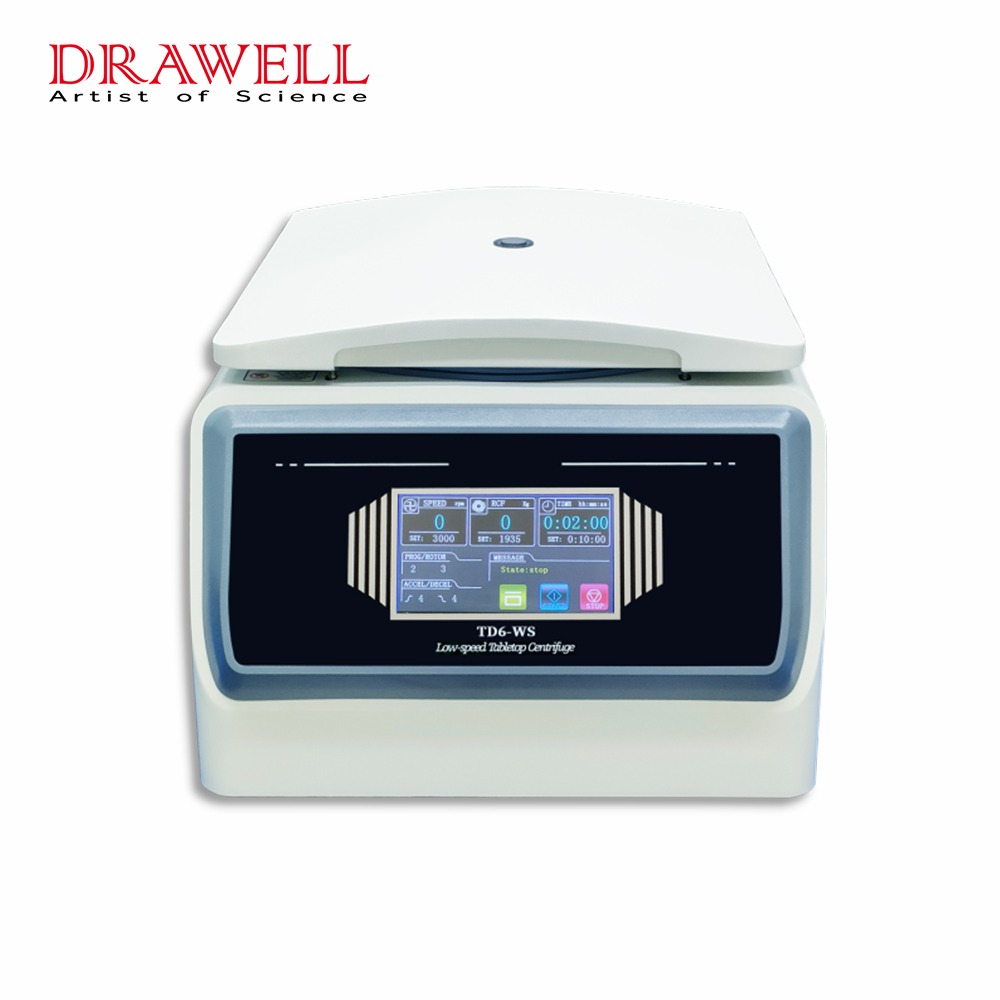

1. Low-speed centrifuge

Its maximum speed is within 10000r/min, relative centrifugal force is within 15000×g, the capacity is tens of milliliters to several liters, and the separation form is solid-liquid sedimentation separation. Clinical laboratories are mainly used for the separation of plasma and serum, as well as the separation of cerebrospinal fluid, pleural effusion, urine, and other formed components. Its structure is relatively simple, and it consists of main components such as a motor, centrifugal turntable (rotor), governor, timer, laboratory centrifuge sleeve, and base.

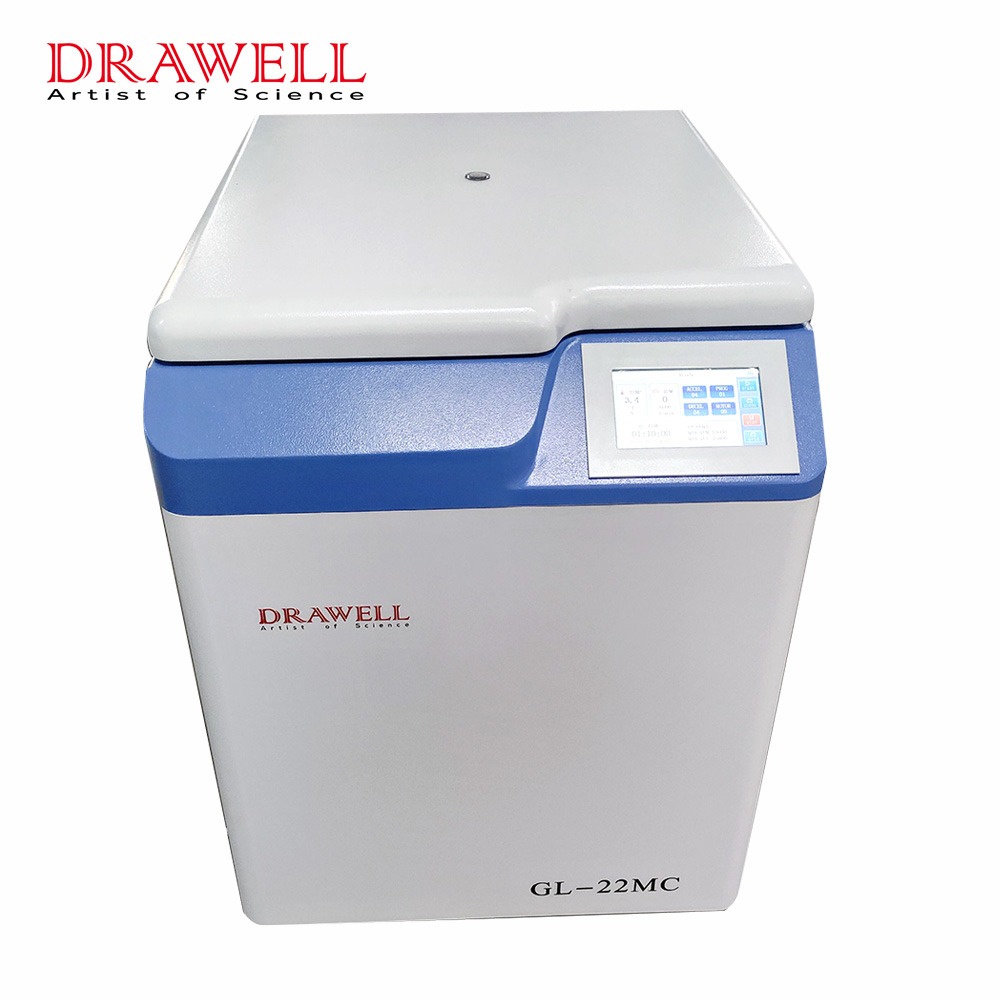

2. High-speed (refrigerated) centrifuge

Its maximum rotational speed is 20000~25000r/min, its maximum relative laboratory centrifuge force is 89000×g, and its maximum capacity can reach 3 liters. The separation form is solid-liquid sedimentation separation.

The clinical laboratory is mainly used for the separation of DNA and RNA in molecular biology and the separation, concentration, and purification of various biological cells, inorganic solutions, suspensions, and colloidal solutions in basic laboratories.

The structure includes a rotating device, a speed control system, a temperature control system, a vacuum system, a centrifugal chamber, a centrifugal rotor, and safety protection devices.

3. laboratory centrifuge for customers:

Widely used in biology, chemistry, petroleum industry, food research, agricultural research, medicine and other scientific research education, schools and production departments, etc., suitable for rapid separation and synthesis of trace samples.

How to Choose a Refrigerated Centrifuge?

To choose an ordinary laboratory centrifuge, according to the size of the workload, is mainly selected from two aspects of speed and capacity. The following is a detailed introduction to the issues that should be paid attention to when purchasing a precision centrifuge:

1. Rotational speed: According to the maximum rotational speed, centrifuges are divided into low-speed centrifuges <10000 rpm/min, high-speed laboratory centrifuges from 10000 rpm/min to 30000 rpm/min, ultra-high-speed centrifuges >30000 rpm/min, each centrifuge All have a rated maximum speed, the maximum speed refers to the speed under no-load conditions, but the maximum speed varies according to the type of rotor and the quality of the sample.

For example, the rated speed of a centrifuge is 16000 rpm/min, which means that the rotor rotates 16000 times per minute when it is empty, and after adding samples, the speed will be less than 16000 rpm/min. Depending on the rotor, the maximum speed is also different. An imported centrifuge can be equipped with multiple rotors. The horizontal rotor can reach 15000 rpm/min, but the angular rotor can reach about 14000 rpm/min.

For specific differences, you need to consult product sales personnel and relevant technical personnel of the manufacturer in detail, so you must be cautious in the selection of the speed, and the maximum speed of the selected centrifuge should be higher than the target speed. For example: if the target speed is 16000 rpm/min, the maximum speed of the selected centrifuge must be higher than 16000 rpm/min.

2. Temperature: Some samples such as protein and cells will be destroyed in a high-temperature environment, so it is necessary to choose a refrigerated centrifuge, which has a rated temperature range. When the laboratory centrifuge is running at high speed, the heat generated by the centrifuge and the cooling system of the centrifuge is balanced at a certain temperature. Generally, the samples that are refrigerated and centrifuged need to be kept at 3°C to 8°C.

The specific temperature is also related to the rotor, such as the rated temperature of a laboratory centrifuge. The temperature range is -10°C to 60°C. When the horizontal rotor is installed, it can reach about 3°C when it rotates. If it is an angle rotor, it may only reach about 7°C. This point should also be consulted in detail with product sales personnel and relevant technical personnel of the production plant.

3. Capacity: How many sample tubes need to be centrifuged each time? How much capacity is required for each sample tube? These factors determine the total capacity of a centrifuge. Simply put, the total capacity of a centrifuge = the capacity of each centrifuge tube × centrifuge tube number, the total capacity, and the size of the workload are matched.

4 Rotors: The rotors of the laboratory centrifuge are mainly divided into two types. Horizontal rotor: the hanging blue is in a horizontal state during operation, and is at right angles to the rotating shaft. The sample will concentrate the sediment at the bottom of the centrifuge tube: Angle rotor: the centrifuge container and the rotating shaft form a fixed angle. The sample concentrates the sediment at the bottom of the centrifuge tube and the side wall near the bottom.

If you want the separated sample to concentrate on the bottom of the laboratory centrifuge tube, choose a horizontal rotor. If you want the sample to concentrate on the bottom of the centrifuge tube and the side wall near the bottom, you should choose an angle rotor.

There are also some special tests or special samples that require special rotors, such as large-capacity hanging baskets are mostly used in blood banks, microplate rotors, slide rotors, PCR rotors, test tube rack rotors, capillary rotors, etc. Rotors have fixed specifications, which are combined with the capacity of the centrifuge, such as a 36×5 ml angle rotor, which determines both the type of rotor and the capacity of the centrifuge, so the selection of the rotor is very important.

5. Control system: High-end centrifuges all adopt microcomputer control systems. These control systems can not only ensure the safe operation of the centrifuge but also automatically complete the work tasks.

Many centrifuges now have better-humanized control systems. For example rotor identification function, safety lock function, fault prompt function, acceleration and deceleration curves, etc. In addition to the above points, pay attention to some details and necessary accessories.

The main component of the laboratory centrifuge is the motor. The motor is divided into a motor with a carbon brush and a motor without a carbon brush. The former has been eliminated. Most of the centrifuges now are brushless motors, and some motors also have a brake function. There are also differences in refrigeration for refrigerated centrifuges. The current environmentally friendly technology is of course fluorine-free refrigeration.

In addition, the noise problem must also be considered. Try to choose a centrifuge with less noise, to maintain a comfortable experimental environment. Be cautious about accessories, some experiments need to use special centrifuge tubes to centrifuge toxic samples or require ultra-

For high-speed centrifuged samples, such centrifuge tubes must be equipped with corresponding sleeves to be safer. There are also some special sample containers, irregular sample bottles, blood bags, etc. These details and accessories must be carefully considered when choosing a centrifuge, otherwise, it will not be able to work normally.

The Price of the Centrifuge

The main reason for the difference in the price of different brands of centrifuges is the performance of the machine.

Centrifuges with refrigeration are much more expensive than ordinary centrifuges. Some centrifuges also have a heating function. The more control programs the higher the price of the centrifuge. The biggest difference is in the configuration. Sometimes the price of the accessories is higher than the price of the host.

When purchasing, you should pay attention to the number and type of rotors selected, plus the necessary centrifuge tubes, tube sleeves, special centrifuge bottles or blood bags, all of which add up to the price of a complete centrifuge.