A bench top centrifuge is a laboratory instrument used to separate substances of different densities within a sample. It consists of a motorized rotor that spins at high speeds, creating centrifugal force. When a sample is placed in the rotor and spun, the centrifugal force causes the denser particles to move towards the outer edges of the rotor, while the lighter components remain closer to the center. This separation allows for the isolation and analysis of different components within a sample, such as cells, proteins, or DNA. Bench top centrifuges are commonly used in various scientific and medical research applications.

What Are the Types of Bench Top Centrifuges?

There are several types of bench top centrifuges commonly used in laboratories.

- Fixed-angle centrifuge: This type of centrifuge has a fixed rotor angle, typically around 45 degrees. It is suitable for pelleting or separating dense particles, such as cell sedimentation.

- Swing-out centrifuge: It has a rotor that swings outward during operation. This type is useful for separating components with varying densities or collecting samples from the bottom of the tubes.

- Microcentrifuge: Microcentrifuges are compact bench top centrifuges designed for small volume samples, typically in microcentrifuge tubes. They offer high speeds and are commonly used in molecular biology and biochemistry applications.

- Refrigerated centrifuge: This type of centrifuge includes a cooling system to maintain low temperatures during operation. It is used when samples require temperature control to prevent degradation or for applications involving sensitive materials like enzymes or proteins.

- High-speed centrifuge: High-speed centrifuges are designed to achieve very high rotational speeds, typically above 10,000 revolutions per minute (rpm). They are used for applications that require efficient separation and pelleting of particles or substances.

What is the Principle of Bench Top Centrifuges?

- The principle of bench top centrifuges is based on the application of centrifugal force to separate and sediment particles or components in a sample. Centrifugal force is generated by rotating the sample at high speeds, causing a radial acceleration that drives the particles away from the center of rotation.

- When a bench top centrifuge is operational, the sample-containing tubes or containers are loaded into the rotor, which is then tightly sealed with a lid. Upon starting the centrifuge, the rotor begins to spin, and the sample experiences an outward force due to the centrifugal acceleration caused by rotation.

- The heavier particles or components in the sample have a greater mass and consequently experience a higher centrifugal force, causing them to move outward and sediment. Separation occurs based on the relative density or mass of the components present in the sample. Heavier particles sediment more quickly and settle at the bottom of the tube, while lighter components remain closer to the top.

- Once the centrifugation process is complete, the rotor slows down or stops, allowing for the retrieval of the separated components. By carefully opening the chamber and removing the tubes, the sedimented materials can be collected or processed further, depending on the specific application.

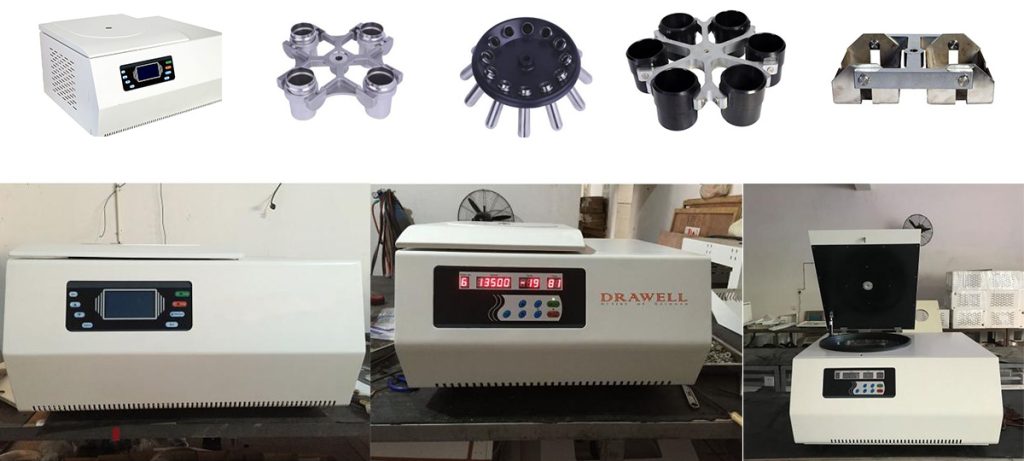

What Are the Parts of Bench Top Centrifuges?

Bench Top centrifuges consist of several essential parts that work together to perform the separation and centrifugation process. Here are the main components:

- Rotor: The rotor is part of the centrifuge that holds the sample tubes or containers. It rotates at high speeds, generating the centrifugal force necessary for separation. The design of the rotor may vary depending on the type and capacity of the centrifuge.

- Motor: The motor is responsible for driving the rotation of the rotor. It provides the power required to spin the samples at high speeds. The motor can be controlled to adjust the speed and duration of centrifugation.

- Control Panel: The control panel allows the operator to set and adjust various parameters, such as speed, time, temperature (in refrigerated centrifuges), and other operating modes specific to the centrifuge model.

- Lid and Safety Features: The centrifuge is typically equipped with a lid that securely seals the centrifuge chamber during operation. Safety features like lid-locking mechanisms and automatic rotor imbalance detection help ensure safe usage by preventing the lid from opening while the rotor is spinning.

- Display: A digital display screen provides information about the centrifuge parameters and settings, such as speed, time remaining, and temperature (in refrigerated centrifuges). It allows the operator to monitor the progress of the centrifugation process.

- Centrifuge Tubes or Carriers: These are containers that hold the samples during centrifugation. They can be in the form of tubes or specialized carriers designed to fit into the rotor. The centrifuge tubes should be matched to the compatibility and capacity specifications of the centrifuge.

- Cooling System (in refrigerated centrifuges): Some bench top centrifuges are equipped with a cooling system, usually in the form of a refrigeration unit, to maintain low temperatures during centrifugation. This feature is beneficial for preserving the stability and integrity of temperature-sensitive samples.

These are the basic components of bench top centrifuges, but additional features and accessories may be present depending on the specific model and intended applications of the centrifuge.

What’re the Applications of Bench Top Centrifuges?

Bench Top centrifuges have a wide range of applications in various fields of research, medicine, and industry. Here are some common applications:

- Cell and Tissue Culture: Bench Top centrifuges are used for pelleting cells and separating cell culture media or components. They are essential for tasks such as cell harvesting, cell fractionation, and isolating cellular organelles.

- Clinical Diagnostics: Centrifugation is a crucial step in clinical diagnostics, enabling the separation of blood components for analysis. Bench Top centrifuges are commonly used in clinical laboratories for tasks such as blood cell counting, serum/plasma separation, and coagulation studies.

- Molecular Biology and Genetics: Bench Top centrifuges are extensively used in molecular biology labs for DNA, RNA, and protein purification, isolation, and extraction. They are employed in techniques such as polymerase chain reaction (PCR), DNA sequencing, and cell lysis.

- Microbiology: Centrifugation is employed in various microbiological applications, including the separation of microorganisms from culture media, the concentration of bacteria or viruses from liquid samples, and antibiotic susceptibility testing.

- Biochemistry and Proteomics: Bench Top centrifuges play a crucial role in biochemical and proteomic research by facilitating the isolation and purification of proteins, subcellular fractions, and protein complexes. They are used in techniques such as Western blotting, immunoprecipitation, and enzyme assays.

- Pharmaceutical Research: Bench Top centrifuges are utilized in drug discovery and development processes, including formulation, purification, and analysis of pharmaceutical compounds. They are used to separate particles, precipitates, and impurities from drug formulations.

- Environmental Science: Centrifugation is employed in environmental research for tasks such as the separation of suspended solids and sediments from water or soil samples. It aids in studying pollutants, environmental contaminants, and microbiological analysis of environmental samples.

- Quality Control and Industrial Applications: find applications in industries such as food processing, biotechnology, and manufacturing, where separation and purification of substances are required for quality control and analysis.

The Pros & Cons of Benchtop Centrifuges

Pros of Bench Top Centrifuges:

- Compact and Portable: Bench Top centrifuges are typically small and easy to fit on laboratory benches. Their portability allows for convenient placement and uses in various settings.

- Cost-effective: Bench Top centrifuges are generally more affordable compared to larger, floor-standing centrifuges, making them more accessible to smaller laboratories or research facilities with limited budgets.

- Versatility: Bench Top centrifuges come in different models with various rotor options, allowing for a wide range of applications. They can accommodate different sample volumes and types, providing versatility in laboratory work.

- Fast Operation: Bench Top centrifuges can reach high rotational speeds quickly, ensuring efficient and rapid separation of samples.

- Ease of Use: These centrifuges are designed for easy operation, often featuring user-friendly controls and interfaces that make them accessible to researchers with varying levels of experience.

Cons of Bench Top Centrifuges:

- Limited Capacity: The sample capacity of Bench Top centrifuges is generally smaller compared to larger models. This can be a limiting factor when working with large sample volumes or when scaling up experiments.

- Lower Maximum Speed: While Bench Top centrifuges can reach high speeds, they often have lower maximum speeds compared to larger floor-standing centrifuges. This can restrict certain applications that require ultra-high centrifugal forces.

- Lack of Advanced Features: Some advanced features, such as refrigeration, automatic rotor identification, or specialized rotors, may be limited in Bench Top centrifuges. These features are typically found in larger, more sophisticated centrifuge models.

- Noise and Vibrations: Bench Top centrifuges, particularly when running at high speeds, can generate noticeable noise and vibrations. This may require additional measures to minimize their impact, such as the use of noise-reduction enclosures or vibration-dampening equipment.

- Limited Cooling Options: Not all Bench Top centrifuges have built-in refrigeration capabilities. This can be a drawback when working with temperature-sensitive samples that require low-temperature environments.