The vacuum drying oven is specially designed for drying heat-sensitive, easily decomposed, and easily oxidized substances. It can maintain a certain degree of vacuum in the workroom during work and can fill the interior with inert gas, especially for some items with complex components. Besides, it can dry quickly, and use an intelligent digital temperature controller to set, display, and control the temperature.

Vacuum drying is a drying method in which the material is placed under negative pressure conditions, and the material is appropriately heated to the boiling point under negative pressure, or the material is solidified and then dried by the melting point by cooling down.

Vacuum Drying Oven Uses

A vacuum drying oven is suitable for heat treatment in a vacuum environment such as defoaming, dehydration, hardening, and drying after cleaning treatment in the production process of electronic products, especially suitable for fast and efficient drying of heat-sensitive items. It is widely used in electronic products and research and application fields such as biochemistry, chemical pharmaceuticals, medical treatment, agriculture, and environmental protection. It is also used for powder drying, baking and disinfection, and sterilization of various glass containers.

How Does a Vacuum-drying Oven Work?

Here is the vacuum drying oven principle. The working space in the vacuum drying oven can be kept to a specified vacuum level, and the temperature is set, displayed, and controlled by an intelligent digital temperature controller. The temperature regulator adopts computer technology to collect and process the temperature signal in the workroom so that the temperature in the workroom can be automatically maintained at a constant temperature.

Intelligent temperature regulators have over-temperature protection functions. During the working process of the equipment, if the temperature in the workroom exceeds the set temperature value, the over-temperature protection circuit will act to cut off the heating circuit.

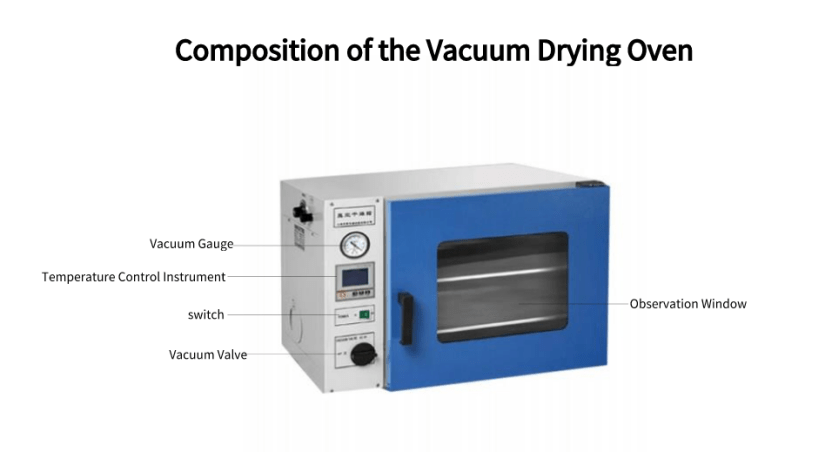

What Is the Composition of the Vacuum Drying Oven?

1. Box structure of the vacuum drying oven

External material: high-quality stainless steel chamber with an anti-static spray treatment. Thus, it is bright clean, and beautiful.

Liner material: Made of high-quality mirror 304 stainless steel. So it is easy to clean.

Shelf material: The aluminum shelf is stamped by a special process, which is not easy to oxidize at high temperatures, conducts heat quickly, and reduces heat loss.

Sealing design: the integrally formed silicone rubber door seal ensures a high vacuum in the box.

Observation window: double-glazed windows are convenient for observing the items in the box.

2. Control system of the vacuum drying oven

Microcomputer temperature controller, accurate and reliable temperature control.

3. Vacuum degree display of the vacuum drying oven

Digital display of vacuum degree is using digital technology to control vacuum degree.

Use Environment Requirements of Vacuum Drying Oven

Here are some conditions of a vacuum drying oven in the following:

1. Temperature: 5~250℃.

2. Relative humidity: ≤85% RH.

3. Power supply voltage: AC 220, V50 Hz.

4. There is no strong vibration or corrosive gas around.

How to Use the Vacuum Drying Oven?

Here is the step-by-step guide for using the vacuum drying oven.

1. Put the samples to be dried into the vacuum drying oven

2. Close the door tightly and release the air valve

3. Connect the vacuum pump to the vacuum valve, open the vacuum valve, and evacuate

4. The vacuum pump’s limit value when the pressure gauge is pumped shall prevail based on its performance.

5. After vacuuming, first close the vacuum valve. If the vacuum valve is not tightly closed, please replace it, and then turn off or remove the power of the vacuum pump. (to prevent the phenomenon of sucking back)

6. The drying cycle needs to be observed every once in a while, and the calendar, the temperature meter, and the changes in the box need to deal with it. If the pressure gauge index drops, there may be air leakage, and the pumping operation can be performed again.

7. After the drying is completed, first open the air release valve to release the gas inside, then open the door of the vacuum drying box and take out the samples after vacuum drying.

Why Is a Vacuum-drying Oven Necessary?

Compared with conventional drying technology, vacuum technology drying has the following advantages:

1. The vacuum environment greatly reduces the boiling point of the liquid to be removed, so vacuum drying can be easily applied to heat-sensitive substances.

2. Vacuum drying can effectively reduce drying time for samples that are difficult to dry, such as powder or other granular materials.

3. Various mechanical parts with complex structures or other porous samples are cleaned and dried by vacuum drying, and no residual substances are left after they are completely dried.

4. Safer to use—-under vacuum or inert conditions, eliminate the possibility of oxides exploding when exposed to heat.

5. Compared with ordinary drying that relies on air circulation, powdered samples are not blown or moved by flowing air.