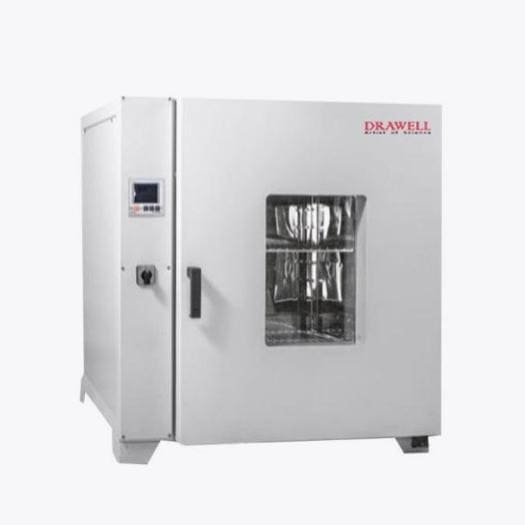

The Infrared Fast Drying Oven adopts the new infrared heating technology. After the infrared element is heated, it can radiate infrared rays above 2-15 microns. When it is absorbed by the heated object, it can be directly converted into heat energy, to obtain the effect of rapid drying, shorten the production cycle, save energy, improve product quality, and achieve other purposes. The Infrared Fast Drying Oven is composed of an infrared radiation source, a drying chamber, an exhaust system, and a mechanical transfer system.

Infrared is an invisible electromagnetic wave with a wavelength range of 0.80 to 1000 μm. Regions with wavelengths below 5.6 μm are usually called near-infrared rays, and areas with wavelengths between 5.6 and 1000 μm are called far-infrared rays. After being radiated by the dry material by infrared energy, the moisture in the material is gasification and drying, so infrared drying is also known as infrared radiation heating and drying. Because most of the absorption bands of infrared radiation are mostly in far-infrared areas, such as water, organic matter, and polymer compounds in far-infrared areas, they have a wide absorption band in the far-infrared areas. Therefore, far-infrared drying is better than near-infrared drying.

Temperature Control of the Infrared Fast Drying Oven

The Infrared Fast Drying Oven adopts an intelligent temperature controller to control temperature, PID parameter self-tuning, solid-state relay to adjust power, non-contact continuous adjustment, and automatically completes the whole drying process, which can meet the temperature control requirements of most users in general. It is easy to operate and reliable in performance. It is equipped with a thermosensitive element probe to form an automatic constant temperature control. The temperature control accuracy is ±1 degree, and the room temperature of ~250 °C can be set arbitrarily. The temperature in the working room can be read directly from the meter. Constant temperature time can be adjusted according to user requirements 0-99.99H.

Advantages of the Infrared Fast Drying Oven

It is a piece of simple equipment and low cost. Besides, it is a convenient and flexible operation. It can adjust the temperature in a short time without interrupting production.

It has a fast drying speed, compared with a hot air dryer. The drying time can be shortened by about 1/3. It has high thermal efficiency and no need to dry Medium. The quality of the dried product is good because both the surface layer and the subsurface layer of the material absorb infrared rays, which can ensure that the drying effect of the product is the same when various materials are made into different shapes.

It can be used in conjunction with other dryers and is easy to be automatically controlled. The system has good airtightness, can avoid the volatilization of solvents or other toxic substances in the drying process, no environmental pollution.

It is no risk of wave leakage and is easy to maintain.

Disadvantages of the Infrared Fast Drying Oven

It is high power consumption. Due to the high frequency and short wavelength of solid heat radiation, the depth of penetration into the material is small, and it is only limited to the drying of thin-layer materials.

Precautions for Using the Infrared Fast Drying Oven

1. There must be a certain space for the place where the Infrared Fast Drying Oven

is placed, and there must be a certain distance between the four sides and the wall. It is recommended to have more than 2M.

2. The arrangement of baked items should not be too dense. Do not place items on the bottom (radiating plate) of the Infrared Fast Drying Oven, so as not to affect the hot air circulation.

3. It is forbidden to bake flammable, explosive items, volatile and corrosive items.

4. Cut off the power supply after baking, and then open the studio door. Remember not to touch the baked items directly with your hands. Use special tools or heat-insulated gloves to pick up the baked items to avoid burns.

5. When using an Infrared Fast Drying Oven, the temperature cannot exceed the maximum operating temperature of the far-infrared drying oven. Generally, the far-infrared drying oven is below 250 degrees.

6. When baking items, the exhaust port on the top must be opened, and the size can be adjusted according to requirements.

7. You must have special instrument control when using it to prevent arbitrary personnel from operating it at will. This is to avoid problems such as confusion in the operation of temperature control instruments.

8. You with special requirements can purchase special Infrared Fast Drying Oven, such as explosion-proof ovens, high-temperature ovens, and program-controlled ovens.