The high pressure homogenizer is also called high-pressure fluid nano-homogenizer, which can make the material in the suspension state flow through the cavity (high pressure homogenizer Cavity)with a special internal structure at a high speed under the action of ultra-high pressure (up to 60,000 psi), so that the material undergoes a series of changes in physical, chemical, structural properties, etc., and finally achieves a homogeneous effect. The pressure of an ordinary homogenizer is within 15000psi, the pressure of high pressure homogenizer is within 30000psi, and the pressure of ultra high pressure homogenizer is within 60000psi.

The Composition Structure of the High Pressure Homogenizer

The high-pressure homogenizer is mainly composed of a high-pressure homogenization chamber and a booster mechanism.

High Pressure Homogenizer Working Principle

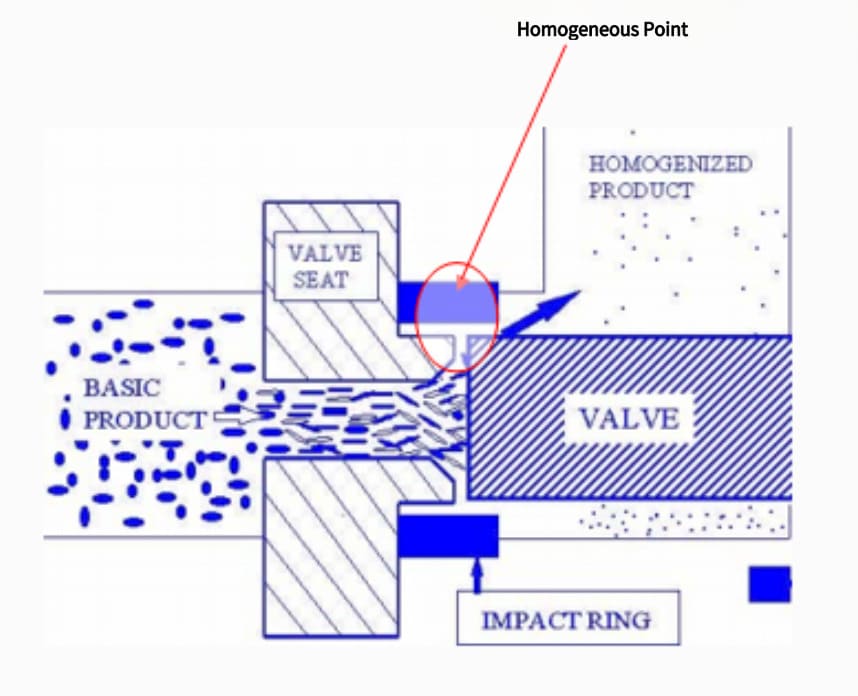

The interior of the high-pressure homogeneous chamber has a specially designed geometry. Under the action of the pressurization mechanism, the high-pressure solution passes through the homogeneous chamber quickly, and the material will be subjected to mechanical mechanisms such as high-speed shearing, high-frequency oscillation, cavitation, and convective impact at the same time. The resulting mechanical force and chemical effect can induce changes in the physical, chemical, and structural properties of material macromolecules, and finally, achieve a homogeneous effect.

Therefore, the high-pressure homogeneous chamber is the core component of the high pressure homogenizer, and its unique internal geometric structure is the main factor that determines the homogenization effect. The booster mechanism provides the required pressure for the fluid material to pass through the homogeneous chamber at high speed. And stability will also affect the quality of the product.

High Pressure Homogenizer Applications

The High-pressure homogenizer is mainly used in biology, medicine, food, chemical industry, and other industries, for cell crushing, drink homogenization, fine chemical industry, preparation of liposome, fat emulsion, nanosuspension, microemulsion, lipid microsphere, vaccines, emulsions, dairy products, infusion solutions, dyes, graphene carbon nanotubes, conductive coatings, and nano-oxide dispersion. Among them, the production of pharmaceutical emulsions must use ultra-high pressure homogenizers, with a pressure of at least 20,000 psi, and high-quality diamond interactive homogeneous chambers to achieve a uniform and safe pharmaceutical-grade particle size distribution.

- The high-pressure homogenizer is used for the preparation of fat particles, microemulsions, liposomes, nanosuspensions, nanoparticles, and microcapsules in the pharmaceutical industry.

- The high-pressure homogenizer is used for cell disruption, microemulsion, and liposome adjuvants of bioengineering products.

- The high-pressure homogenizer is used for the homogenization and emulsification of food and beverage industry products, improving product stability, taste, appearance, and effective packaging of nutrients.

- The high-pressure homogenizer is used for the homogeneous dispersion of products in cosmetics, fine chemicals, and other industries to improve functionality, differentiate and increase added value, and ensure process stability, etc.

- The high-pressure homogenizer is used for dispersion and stripping of conductive paste, resistive paste, graphene, carbon nanotube, nano oxide, etc.

Sample examples by using the High Pressure Homogenizer

1. Vegetable protein: soybean protein, peanut protein, sweet potato protein, etc.

2. Plant tissue: tremella spores, hawthorn leaves, loquat leaves, rhizomes of ginger plants, etc.

3. Algal cells: Spirulina cells, Nostoc hairy cells, Chlorella cells, etc.

4. Microorganisms: Yeast, Escherichia coli, Schizochytrium, etc.

5. Liquid food: food and beverage, dairy products, jelly, etc.

6. Paint color paste: carbon black paint color paste, phthalocyanine green paint color paste, phthalocyanine blue paint color paste, purple 23 paint color paste, etc.

When you talk about the multi-faceted application of high-pressure homogenizers, only Drawell products have extensive experience in this area and have countless practical application examples and technologies. This also means that you can select the most suitable high pressure homogenizer for your actual needs and use it here. As long as you contact us, you will be pleasantly surprised to find that we are trying to understand and study the basic knowledge of your industry and the actual preparation and other specialized technologies. Our team, as an equipment supplier and after-sales service provider of the high pressure homogenizer.