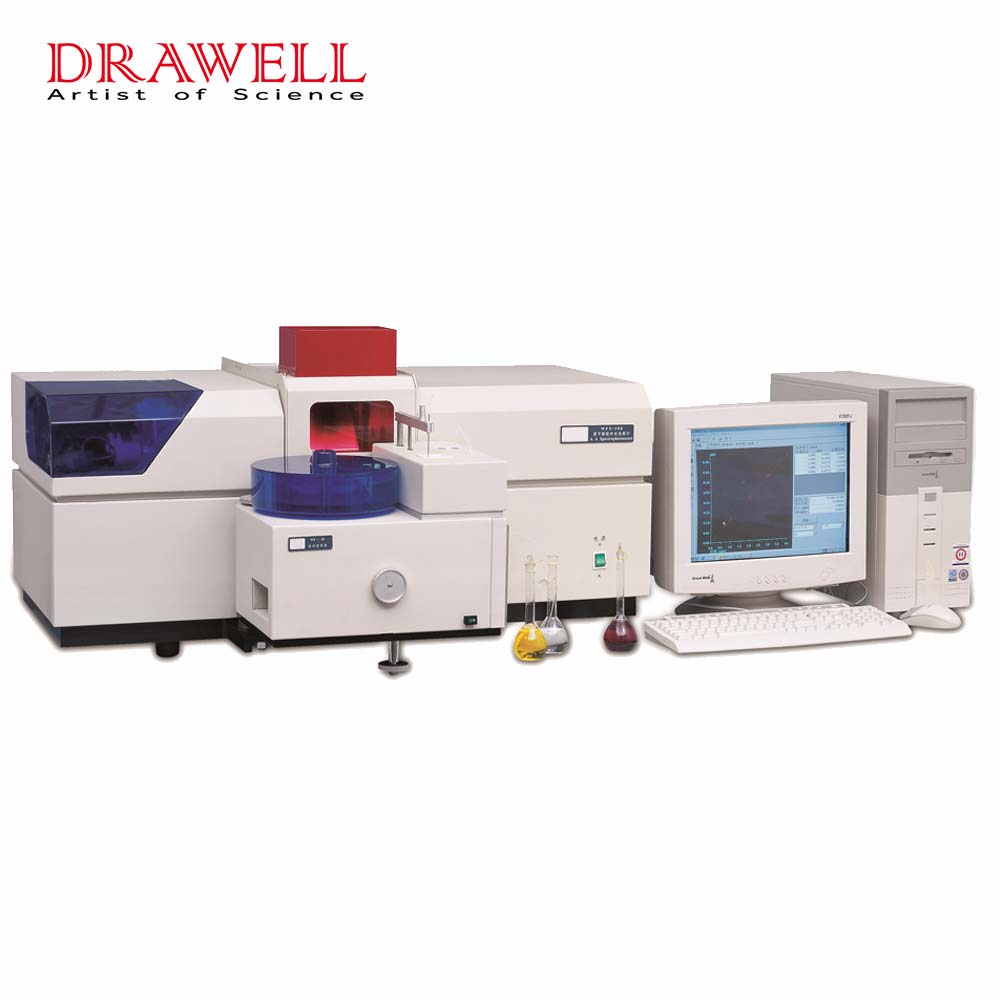

Feature of Atomic Absorption Spectrophotometer DW-200

Integrated flame/graphite furnace atomization system, changeable with flame emission burner

- Automatically controlled changeover of the integrated flame and graphite furnace atomizer featuring easy operation and time-saving eliminate human labor.

- A flame emission burner head can be installed to perform flame emission analysis on Alkali metals such as K, Na, etc.

Accurate fully automated control system

- Automatic 6-lamp turret, automatic adjustment of lamp current, and optimization of light beam position.

- Automatic wavelength scanning and peak picking

- Automatic spectral bandwidth changing

- Automatic changeover between flame and graphite furnace operation, automatic optimization of position parameters, automatic ignition, and automatic gas flow setting

Reliable fully automatic graphite furnace analysis

- Adopting FUZZY-PID and dual curve mode light-controlled temperature control technique, temperature auto-correction technique, ensures fast heating, good temperature reproducibility, and high analytical sensitivity. The temperature control accuracy is less than 1%.

- Graphite furnace with pneumatic control and pressure lock ensures constant pressure and reliable contact.

- The multi-function auto sampler features automatic standard sample preparation, automatic correction of sampling probe depth, automatic tracing, and correction of liquid surface height in the sample vessel, with a sampling accuracy of 1% and reproducibility of 0.3%, realizing full automation of graphite furnace analysis.

Perfect safety protection measures

- Alarm and automatic protection to fuel gas leakage, abnormal flow, insufficient air pressure, and abnormal flame extinction in the flame system;

- Alarm and protection function to insufficient carrier gas and protective gas pressure, insufficient cooling water supply, and overheating in a graphite furnace system.

Advanced and reliable electronic design

- Adopting large-scale programmable logic array and Inter I2C bus technology

- European-type sockets and AMP adapters with high reliability to ensure long-term reliability of the whole electronic system.

Easy and practical analysis software

- Easy-to-use AAS analysis software is made under the Windows operating system, realizing fast parameter setting and optimization.

- Automatic sample dilution, automatic curve fitting, automatic sensitivity correction.

- Automatic calculation of sample concentration (content), mean value, standard deviation, and relative standard deviation calculation.

- Multi-elements determination in sequence to the same sample.

- Measured data and final results can be printed out and edited in Excel format.

SPECIFICATIONS

| Main Specification | Wavelength range | 190-900nm |

| Wavelength accuracy | Better than ±0.25nm | |

| Resolution | Two spectral lines of Mn at 279.5nm and 279.8nm can be separated with the spectral bandwidth of 0.2nm and valley-peak energy ratio less than 30%. | |

| Baseline stability | 0.004A/30min | |

| Background correction | The D2 lamp background correction capability at 1A is better than 30 times. | |

| The S-H background correction capability at 1.8A is better than 30 times. | ||

| Light Source System | Lamp turret | Motorized 6-lamp turret (Two high performance HCLs can be mounted on the turret to increase the sensitivity in flame analysis.) |

| Lamp current adjustment | Wide pulse current: 0~25mA, Narrow pulse current: 0~10mA. | |

| Lamp power supply mode | 400Hz square wave pulse; | |

| 100Hz narrow square wave pulse + 400Hz wide square pulse wave. | ||

| Optical System | Monochomator | Single beam, Czerny-Turner design grating monochromator |

| Grating | 1800 l/mm | |

| Focal length | 277mm | |

| Blazed Wavelength | 250nm | |

| Spectral Bandwidth | 0.1nm, 0.2nm, 0.4nm, 1.2nm, auto switch over | |

| Flame Atomizer | Burner | 10cm single slot all-titanium burner |

| Spray chamber | Corrosion resistant all-plastic spray chamber. | |

| Nebulizer | High efficiency glass nebulizer with metal sleeve, sucking up rate: 6-7mL/min | |

| Emission burner provided | ||

| Graphite Furnace | Temperature range | Room temperature~3000ºC |

| Heating rate | 2000℃/s | |

| Graphite tube dimensions | 28mm (L) x 8mm (OD) | |

| Characteristic mass | Cd≤0.8 ×10-12g, Cu≤5 ×10-12g, Mo≤1×10-11g | |

| Precision | Cd≤3%, Cu≤3%, Mo≤4% | |

| Detection and Data Processing System | Detector | R928 photomultiplier with high sensitivity and wide spectral range. |

| Software | Under Windows operating system | |

| Analytical method | Working curve auto-fitting; standard addition method; automatic sensitivity correction; automatic calculation of concentration and content. | |

| Repeat times | 1~99 times, automatic calculation of mean value, standard deviation and relative standard deviation. | |

| Multi-task Functions | Sequential determination of multi-elements in the same sample. | |

| Condition reading | With model function | |

| Result printing | Measurement data and final analytical report printout, editing with Excel. | |

| Standard RS-232 serial port communication | ||

| Graphite Furnace Autosampler | Sample tray capacity | 55 sample vessels and 5 reagent vessels |

| Vessel material | Polypropylene | |

| Vessel volume | 3ml for sample vessel, 20ml for reagent vessel | |

| Minimum sampling volume | 1μl | |

| Repeatable sampling times | 1~99 times | |

| Sampling system | Accurate dual pump system, with 100μl and 1ml injectors. | |

| Characteristic Concentration and Detection Limit | Air-C2H2 flame | Cu: Characteristic concentration ≤ 0.025 mg/L, Detection limit≤0.006mg/L; |

| Function Expansion | Hydride vapor generator can be connected for hydride analysis. | |

| Dimensions and Weight | Main unit | 107X49x58cm, 140kg |

| Graphite furnace | 42X42X46cm, 65kg | |

| Autosampler | 40X29X29cm, 15kg | |