Alloy analysis is crucial in various industries to ensure material quality, compliance with regulations, and the integrity of manufactured products. Among the many tools available for alloy analysis, Drawell Handheld XRF Analyzers stand out for their portability, accuracy, and ease of use. This article delves into the importance of alloy analysis, the different types of alloy analyzers available, and why Drawell Handheld XRF Analyzers are a preferred choice.

Importance of Alloy Analysis

Alloys are combinations of metals designed to have specific properties for different applications. Accurate alloy analysis is vital for several reasons:

- Quality Control: Ensures that the materials used meet the required specifications and standards.

- Regulatory Compliance: Helps in adhering to industry regulations and standards, such as those in the aerospace and automotive sectors.

- Material Verification: Verifies the composition of materials to prevent costly errors and ensure the safety and performance of products.

- Cost Savings: Identifies the correct materials, reducing waste and avoiding the use of expensive or inappropriate metals.

In industries such as aerospace, automotive, construction, and manufacturing, the importance of reliable and accurate alloy analysis cannot be overstated.

Different Types of Alloy Analyzers

Different alloy analyzers are used in various industries to identify and quantify the composition of metallic materials. Each type of analyzer employs a different technology suited to specific applications and requirements. Here are some of the most common types of alloy analyzers:

| Type of Analyzer | Principles | Applications |

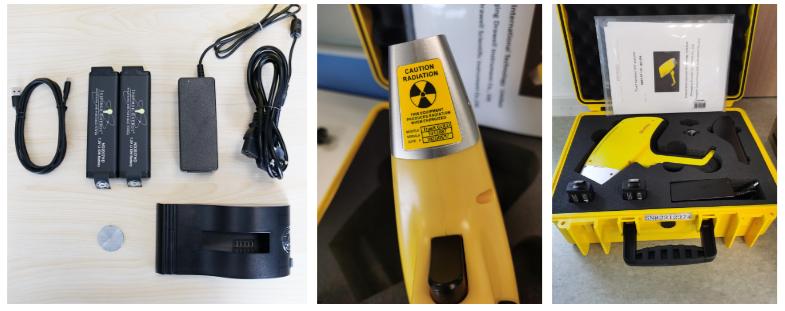

| Handheld XRF Analyzers | Use X-ray fluorescence to excite atoms in the sample and measure the emitted secondary X-rays. | Scrap metal recycling, quality control, field inspections. |

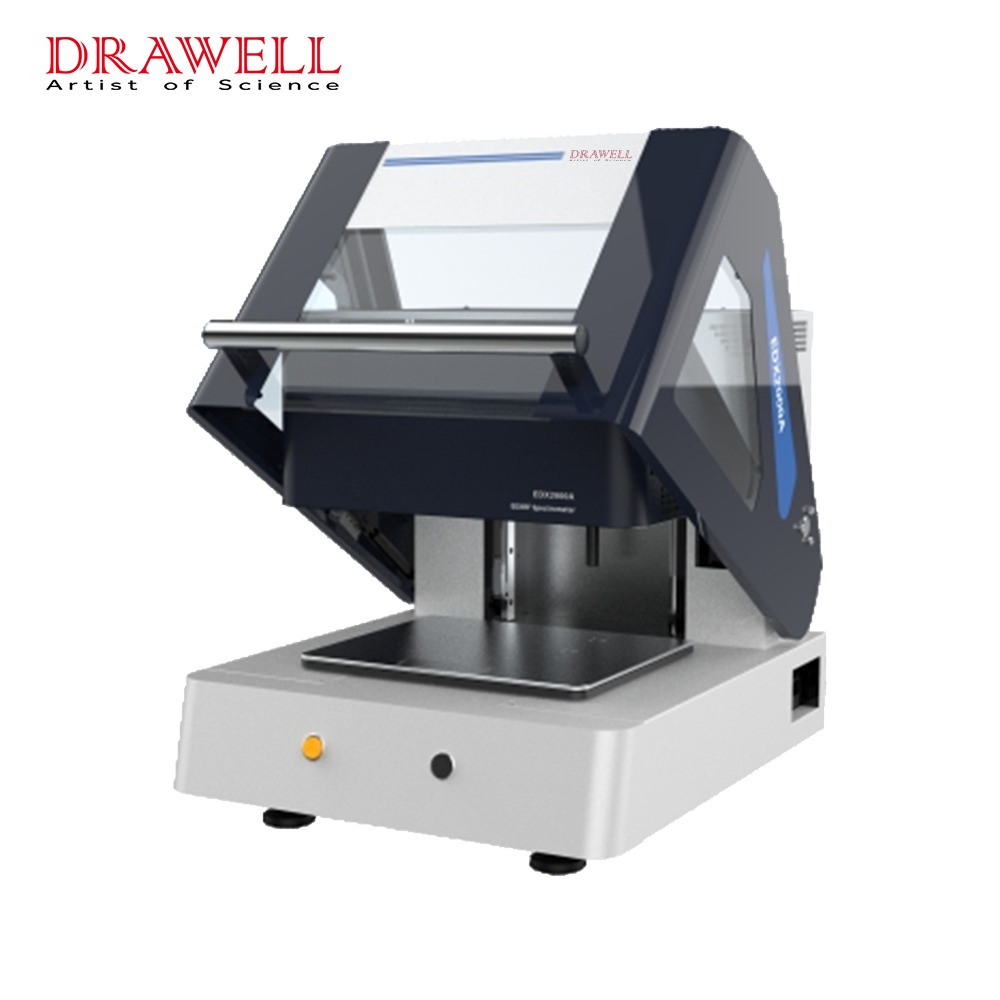

| Benchtop XRF Analyzers | Use X-ray fluorescence in a larger, stationary unit for more detailed analysis. | Laboratory settings, detailed material research, high-precision quality control. |

| Mobile OES Analyzers | Use spark or arc excitation to excite atoms in the sample and measure the emitted light. | On-site metal sorting, PMI (Positive Material Identification), large component analysis. |

| Stationary OES Analyzers | Use spark or arc excitation in a fixed unit for high-precision analysis. | Metallurgical labs, foundries, detailed alloy characterization. |

| Handheld LIBS Analyzers | Use laser pulses to ablate the sample surface and analyze the emitted light. | Real-time alloy identification, scrap sorting, fieldwork requiring fast results. |

| Benchtop LIBS Analyzers | Use laser pulses in a larger, lab-based unit for more detailed analysis. | Research laboratories, quality control, precise material analysis. |

| ICP-OES Analyzers | Use plasma to excite atoms and measure the emitted light in a lab-based setup. | Detailed compositional analysis, trace element detection, high-purity material analysis. |

| Atomic Absorption Spectroscopy (AAS) | Measure the absorption of light by vaporized atoms in a lab-based setup. | Trace metal analysis, environmental testing, laboratory research. |

| Mass Spectrometry (MS) Analyzers | Ionize the sample and measure mass-to-charge ratios of ions in a sophisticated lab-based instrument. | Ultra-trace analysis, isotopic analysis, detailed compositional studies. |

The choice of an alloy analyzer depends on specific needs, including the required precision, speed, portability, and budget. Handheld XRF analyzers like those from Drawell are popular for their convenience and quick results, making them suitable for many industrial applications. More advanced techniques like ICP-OES and MS are used for detailed analysis in laboratory settings.

Why Choose Drawell Handheld XRF Analyzers?

Available for Various Alloy Types

Drawell Handheld XRF Analyzers are capable of testing a wide range of alloy types across various industries. Here are the primary categories of alloys that can be analyzed using these devices:

1. Ferrous Alloys

Steel: Including various grades such as carbon steel, stainless steel, tool steel, and alloy steel.

Cast Iron: Different types like gray iron, ductile iron, and white iron.

2. Non-Ferrous Alloys

Aluminum Alloys: Common types like 1000, 2000, 3000, 5000, 6000, and 7000 series.

Copper Alloys: Including brass, bronze, and other copper-based alloys.

Nickel Alloys: Various nickel-chromium, nickel-iron, and nickel-copper alloys.

Titanium Alloys: Such as commercially pure titanium and titanium-aluminum-vanadium alloys.

3. Precious Metal Alloys

Gold Alloys: Including various karat golds and gold-silver-copper alloys.

Silver Alloys: Sterling silver, coin silver, and other silver-based alloys.

Platinum Group Metals: Alloys containing platinum, palladium, rhodium, and other platinum group elements.

4. Specialty Alloys

Superalloys: Nickel-based, cobalt-based, and iron-based superalloys used in high-temperature applications.

10 Key Features

Drawell Handheld XRF Analyzers are equipped with various features that make them effective and user-friendly for alloy analysis. Here are some of the key features:

1. Portability and Convenience

Compact Design: Lightweight and handheld, making them easy to carry and use in the field.

Ergonomic Grip: Designed for comfortable handling during prolonged use.

2. Advanced Technology

High-Resolution Detectors: Equipped with advanced detectors that provide accurate and reliable results.

X-ray Tube: Utilizes a powerful X-ray tube for efficient excitation of sample elements.

Multiple Calibration Modes: Offers various calibration options to enhance accuracy for different types of materials and alloys.

3. User-Friendly Interface

Touchscreen Display: Intuitive, easy-to-navigate touchscreen interface.

Pre-Installed Software: Comes with user-friendly software for quick setup and operation.

Real-Time Data: Displays real-time analysis results on the screen for immediate decision-making.

4. Accuracy and Precision

High Sensitivity: Capable of detecting trace elements and providing precise compositional analysis.

Repeatability: Ensures consistent results across multiple measurements.

5. Speed and Efficiency

Rapid Analysis: Provides fast results, typically within seconds, enabling quick decision-making.

On-Site Testing: Eliminates the need for sample transport to a laboratory, saving time and costs.

6. Data Management and Connectivity

Data Storage: Internal memory for storing thousands of test results.

Data Export: Options for exporting data via USB, Bluetooth, or Wi-Fi for further analysis and reporting.

Report Generation: Built-in capability to generate detailed reports directly from the device.

7. Versatility

Multi-Element Detection: Can analyze a wide range of elements simultaneously, suitable for various alloy types.

Adjustable Settings: Flexible settings to accommodate different analysis needs and sample types.

8. Safety Features

Radiation Safety: Built-in safety features to protect users from X-ray exposure, including automatic shutdown and interlocks.

Robust Design: Durable construction to withstand harsh environments and rigorous use.

9. Additional Features

Battery Life: Long-lasting battery for extended field use without the need for frequent recharging.

GPS Functionality: Built-in GPS for geolocation tagging of analysis results, useful for field applications.

Customizable Libraries: Allows customization of element libraries to tailor the device to specific applications or industry standards.

10. Support and Service

Training and Support: Comprehensive user manuals, training materials, and customer support to ensure users can effectively operate the device.

Maintenance and Calibration: Services for regular maintenance and calibration to keep the device performing optimally.

Various Applications

- Quality Control: Ensuring materials meet required specifications in manufacturing processes.

- Scrap Metal Recycling: Identifying and sorting different types of metals for recycling purposes.

- Regulatory Compliance: Ensuring materials comply with industry standards and regulations.

- Field Inspections: On-site analysis of materials in construction, mining, and other industries.

In summary, Drawell Handheld XRF Analyzers are versatile, accurate, and efficient tools designed for a wide range of alloy analysis applications. Their advanced technology, user-friendly interface, and robust features make them a valuable asset for professionals in various industries.