Refrigerated centrifuges provide precise temperature control for sensitive biological samples. Recent advancements in refrigeration technology have significantly enhanced the performance, efficiency, and versatility of these critical instruments.

What are Refrigerated Centrifuges

Refrigerated centrifuges are specialized laboratory instruments designed to separate samples based on their density through high-speed spinning. By spinning samples at high speeds, refrigerated centrifuges create centrifugal force that separates components based on their density, with heavier particles moving to the bottom of the tubes and lighter ones remaining closer to the top. They incorporate refrigeration systems to maintain precise, low temperatures during the centrifugation process, which is crucial for preserving the integrity of temperature-sensitive samples such as biological specimens and chemical solutions.

Importance of Refrigeration Technology Used in Refrigerated Centrifuges

Refrigeration technology in refrigerated centrifuges is crucial for several reasons:

- Temperature Control: Many biological and chemical samples need to be processed at specific temperatures to maintain their stability and integrity. Refrigeration ensures that the samples are kept at the required temperature throughout the centrifugation process.

- Preventing Sample Degradation: Temperature-sensitive samples, such as enzymes, proteins, and certain chemicals, can degrade if exposed to high temperatures. Refrigeration prevents this degradation by keeping the samples cool.

- Improving Separation Efficiency: The efficiency of centrifugation can be affected by temperature. Lower temperatures can help to increase the density difference between the components being separated, leading to more effective separation.

- Preserving Sample Integrity: For long-term storage or multiple-step processes, maintaining a consistent temperature is crucial to ensure the samples’ quality and accuracy of results.

- Reducing Risk of Heat-Generated Artifacts: During high-speed centrifugation, heat is generated. Refrigeration helps mitigate the heat buildup, which could otherwise affect the sample and the centrifuge’s performance.

- Compliance with Protocols: Many scientific protocols and procedures require specific temperature conditions. Refrigerated centrifuges ensure that these conditions are met, facilitating compliance with research and clinical standards.

Traditional Refrigeration Technology Used in Refrigerated Centrifuges

This chart highlights some of the main aspects of traditional refrigeration technology used in refrigerated centrifuges, focusing on factors like refrigerants, control system, efficiency, and environmental impact.

| Components and Features | Traditional Refrigeration Technology |

| Refrigerant Used | Freon (e.g., R-12, R-22) or other chlorofluorocarbons (CFCs) |

| Cooling Mechanism | Vapor-compression refrigeration cycle |

| Temperature Range | Typically from 4°C to 25°C |

| Energy Efficiency | Generally less efficient, higher energy consumption |

| Environmental Impact | High global warming potential and ozone depletion |

| Maintenance Requirements | Regular maintenance required to handle refrigerant leaks |

| Cost | Moderate initial cost but higher operational costs due to energy consumption |

| Control System | Mechanical thermostats or basic electronic controls |

| Design Complexity | Relatively simple and robust design |

| Noise Level | Moderate to high noise levels due to compressor operation |

| Compressor | Electric motor that pumps refrigerant gas through the system, creating pressure difference for cooling. |

| Refrigerant Gas | Specialized fluid that undergoes phase changes (liquid to gas and vice versa) to absorb and release heat during the refrigeration cycle. |

| Capillary Tube (Optional) | Thin tube that restricts refrigerant flow, acting as a simple pressure control mechanism. (Less common in modern centrifuges) |

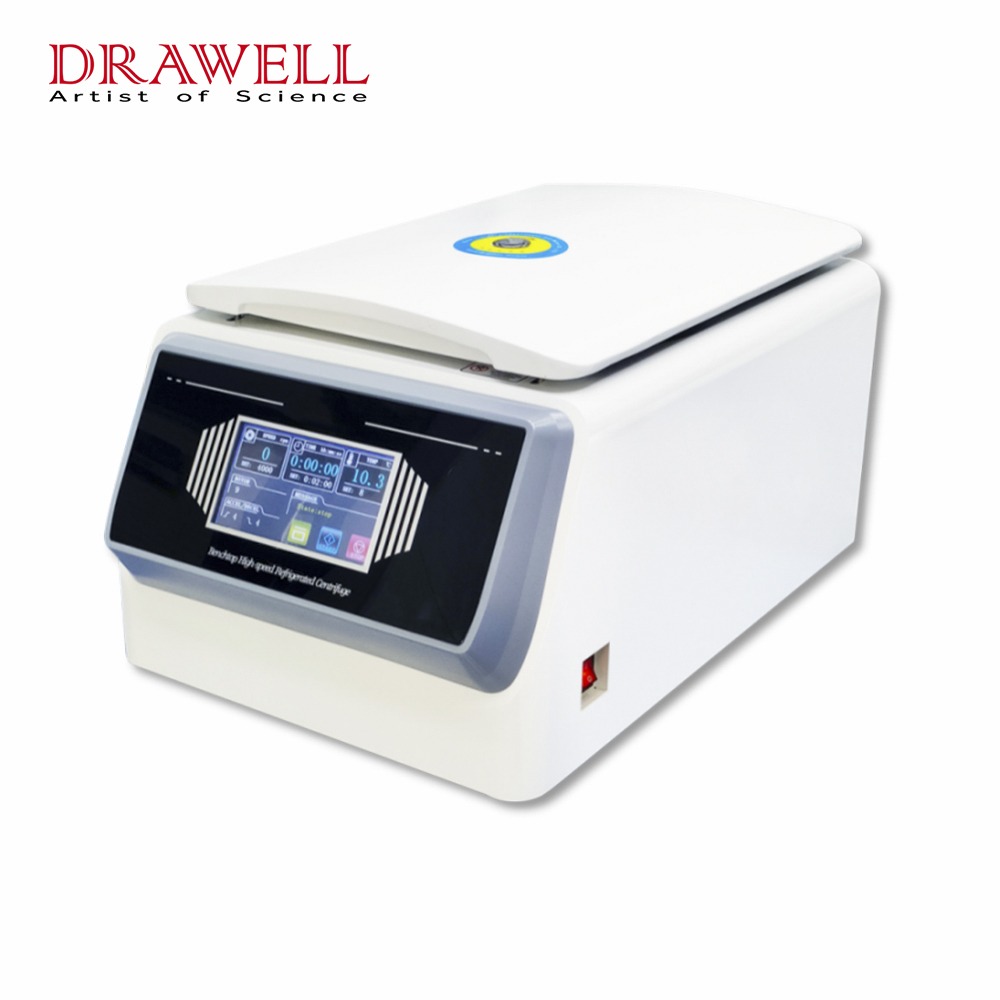

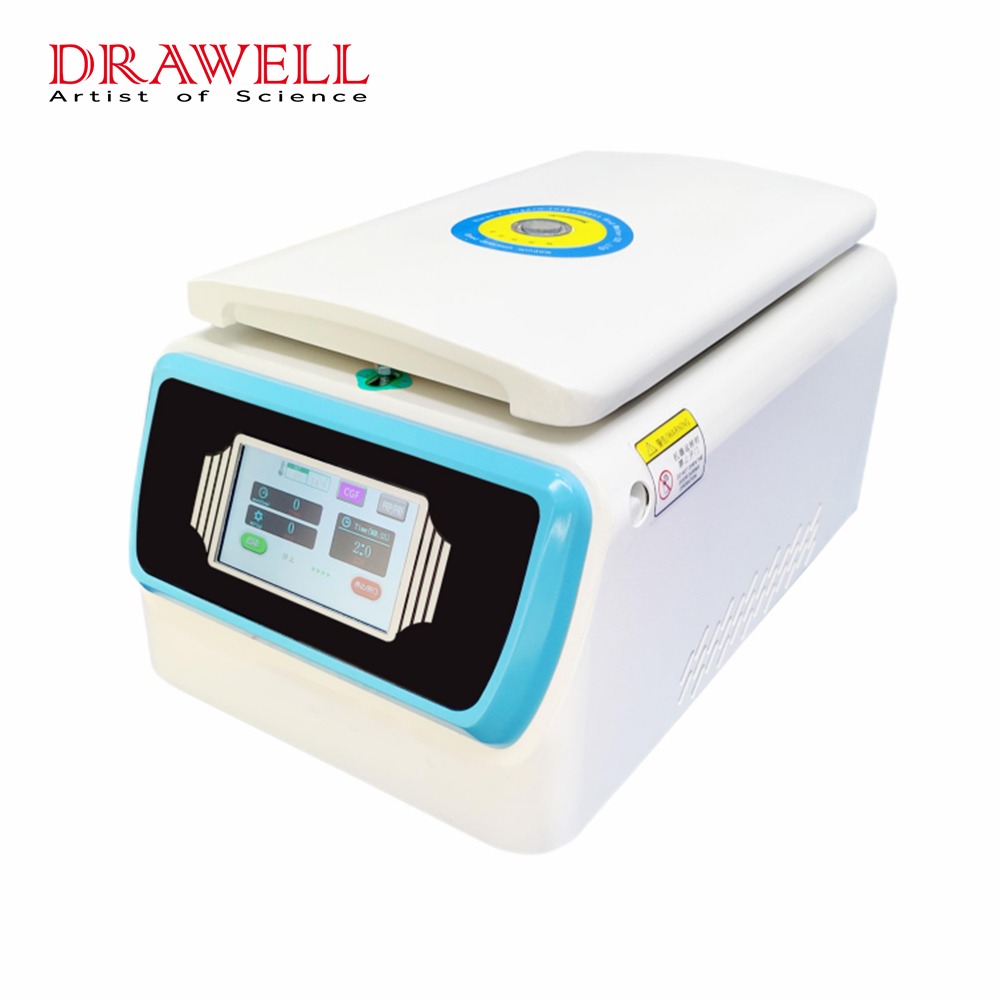

Refrigerated Centrifuge display

Key Innovations in Refrigeration Technology Used for Refrigerated Centrifuges

1. Energy Efficiency and Eco-Friendly Refrigerants

Modern refrigerated centrifuges are designed with enhanced energy efficiency in mind. Recent innovations include the use of variable speed compressors and advanced thermal insulation materials that reduce power consumption. Variable speed compressors adjust their operation based on the cooling demand, which minimizes energy waste.

Additionally, the shift to eco-friendly refrigerants marks a major step forward. Traditional refrigerants like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) have been replaced with more sustainable options such as hydrofluoroolefins (HFOs) and hydrocarbons (HCs). These new refrigerants have lower global warming potential (GWP) and are less harmful to the environment, aligning with global efforts to reduce greenhouse gas emissions.

2. Advanced Temperature Control

The precision of temperature control in refrigerated centrifuges has improved significantly. Modern centrifuges are equipped with high-accuracy sensors and advanced control systems that ensure stable and consistent temperatures. This level of control is crucial for experiments that require strict temperature conditions to avoid sample degradation and ensure reliable results.

3. Rapid Cooling and Heating

New refrigeration technologies have introduced rapid cooling and heating capabilities in refrigerated centrifuges. This feature is particularly useful for processes that require quick temperature adjustments. Fast cooling systems can bring the centrifuge chamber to the desired temperature much more quickly than older models, streamlining workflows and reducing processing times.

4. Noise Reduction

Recent developments have also focused on reducing the operational noise of refrigerated centrifuges. Quieter compressors and improved vibration isolation have led to lower noise levels, making laboratory environments more comfortable and less disruptive. This is especially important in labs where multiple centrifuges are operating simultaneously.

5. Digital Integration and Smart Features

The integration of digital technology has transformed the operation of centrifuges. Many modern intelligent refrigerated centrifuges feature user-friendly touchscreens, wireless connectivity, and advanced software that allow for remote monitoring and control. These digital features enable users to track performance metrics, adjust settings, and receive real-time alerts, enhancing operational efficiency and reliability.

6. Enhanced Safety Features

Safety remains a top priority in laboratory equipment design. Advances in refrigeration technology have led to improved safety features in refrigerated centrifuges. Modern units often include enhanced insulation, automatic shut-off systems, and fail-safes that protect both the samples and the equipment from potential failures or malfunctions.

7. User-Friendly Designs

Ergonomics and ease of use have been major considerations in recent centrifuge designs. Improvements in user interfaces, ease of maintenance, and intuitive controls contribute to a more user-friendly experience. Features such as easy-to-clean surfaces and modular designs for simple part replacement make these instruments more accessible and easier to operate.

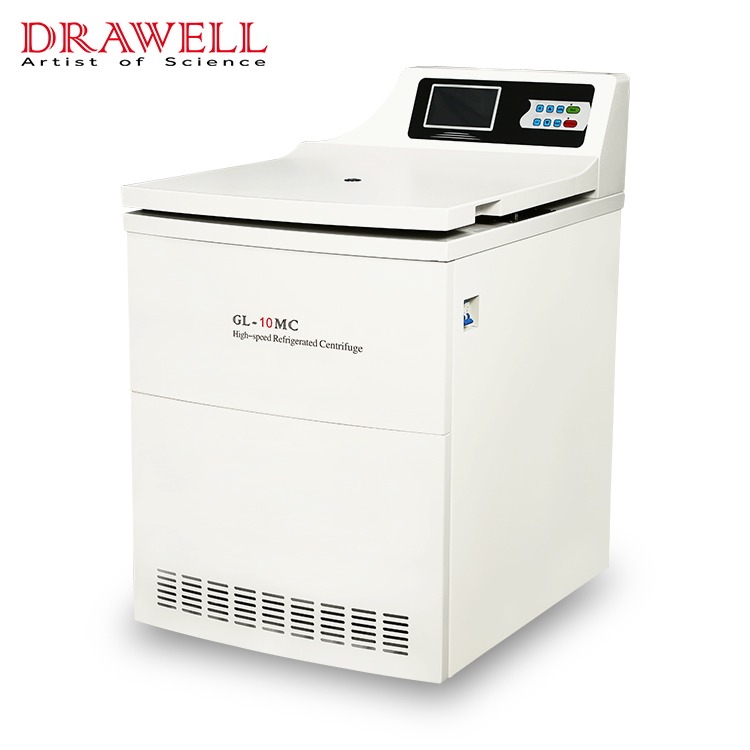

Get Advanced Refrigerated Centrifuges from Drawell

Drawell provides a range of refrigerated centrifuges adopting advanced refrigeration technology, suitable for various laboratory applications. These centrifuges are designed to provide precise temperature control and high-speed performance, ensuring the stability and integrity of temperature-sensitive samples.

Key features of Drawell Refrigerated Centrifuges

- Temperature Control: Precise temperature regulation to protect heat-sensitive samples.

- High Speed: High-speed refrigerated centrifuge is capable of reaching high speeds for efficient separation processes.

- Versatility: Compatible with a variety of rotors and tubes to accommodate different sample types.

- Safety Features: Equipped with safety mechanisms such as imbalance detection, lid lock, and emergency stop functions.

- User-Friendly Interface: Intuitive controls and digital displays for easy operation and monitoring.

Drawell centrifuges are ideal for use in molecular biology, biochemistry, clinical lab and other research field which require reliable and efficient sample processing.