A centrifuge is a vital laboratory tool that is utilized for a wide range of scientific, medical, and industrial purposes. Centrifugal force is used by these powerful devices to separate and analyze distinct components inside a sample. Centrifuges generate enormous gravitational forces by spinning samples at high speeds, resulting in the separation of components depending on density and molecular weight. In this article, we will discuss the topic of how a centrifuge works from 4 key points including principle, key components, centrifugation process, and types of centrifugation.

Principle of Centrifugal Force in a Centrifuge

The centrifugal force principle is essential to the operation of a centrifuge. The apparent outward force experienced by an item moving in a circular direction is known as centrifugal force. This force is generated in a centrifuge by the high-speed rotation of the rotor, which causes the material within the centrifuge tubes to separate based on density and molecular weight.

When a rotor spins quickly, it generates a centrifugal or gravitational field that acts perpendicular to the axis of revolution. The centrifugal force pushes the particles or components of the sample away from the center of rotation. The magnitude of the centrifugal force depends on the rotational speed of the rotor and the distance of the particles from the axis of rotation. As a result, denser particles tend to migrate to the sample container’s bottom, whereas lighter particles or components migrate to the top.

The working principle of centrifugal force allows for the separation and stratification of substances within a sample. Denser particles, with a higher mass or density, have a larger centrifugal force and are forced to travel to the sample container’s outer edges. Lighter particles, on the other hand, receive less centrifugal force and prefer to stay closer to the center.

It is possible to modify the centrifugal force to achieve specific separation goals by altering the rotating speed, duration of centrifugation, and other parameters. Cells, organelles, and particulate debris, for example, can be isolated from the sample based on their densities and molecular weight.

The principle of centrifugal force enables efficient and rapid separation, making centrifugation a valuable technique in various fields including biology, chemistry, medicine, and industry, due to the notion of centrifugal force. It enables the isolation, purification, and analysis of various components inside a sample, which helps with research, diagnostics, and process improvement.

Key Components of a Centrifuge

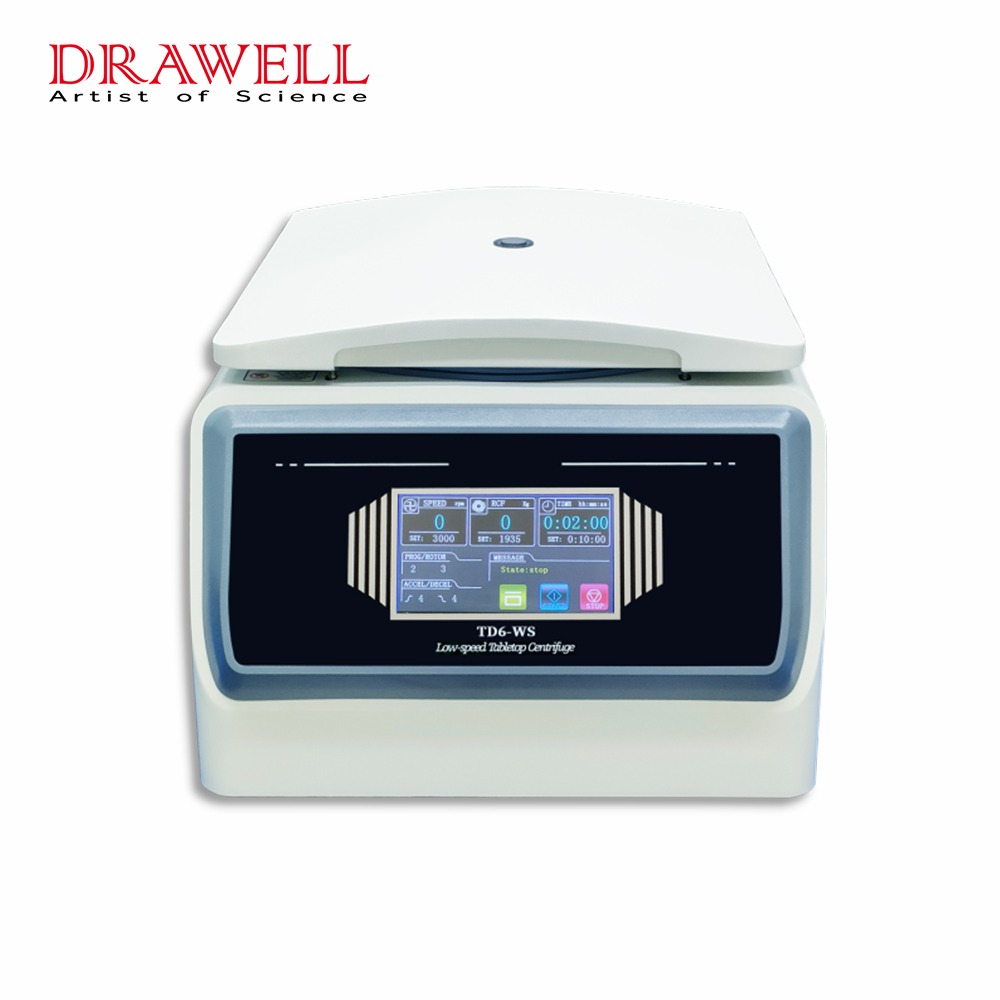

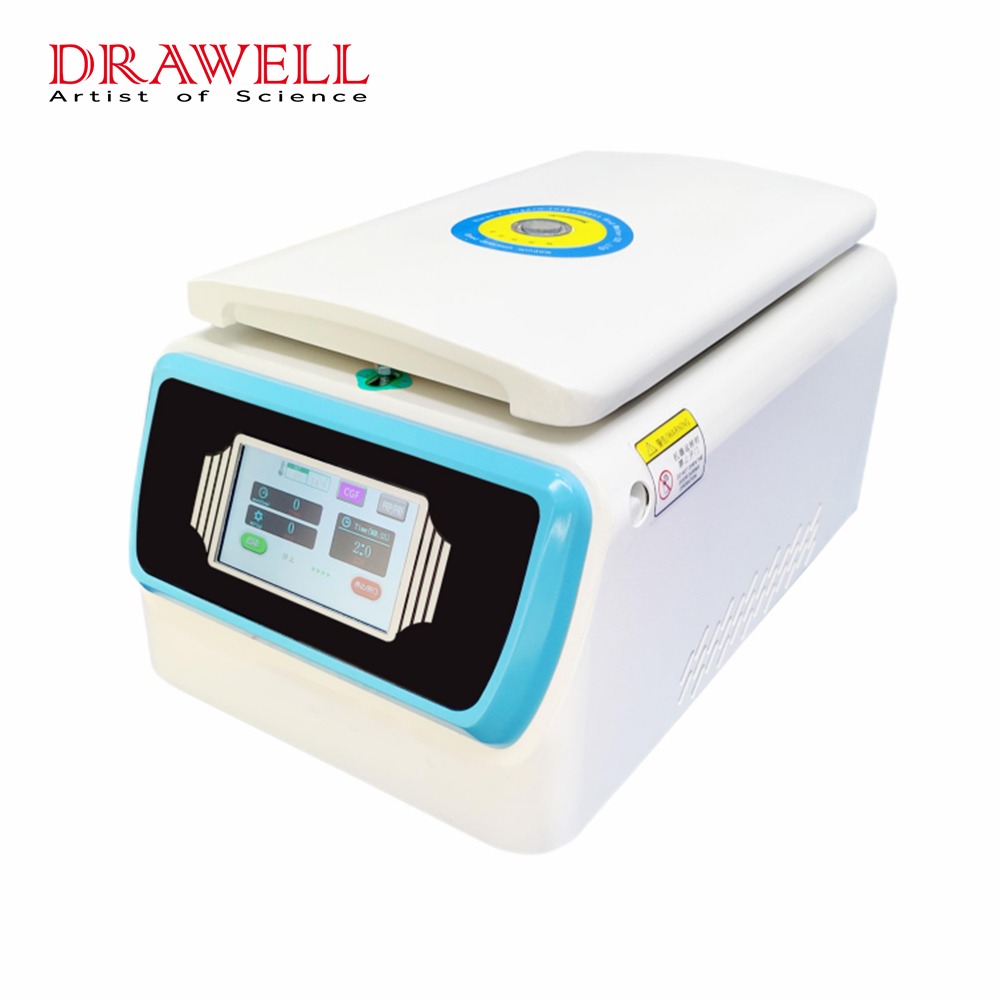

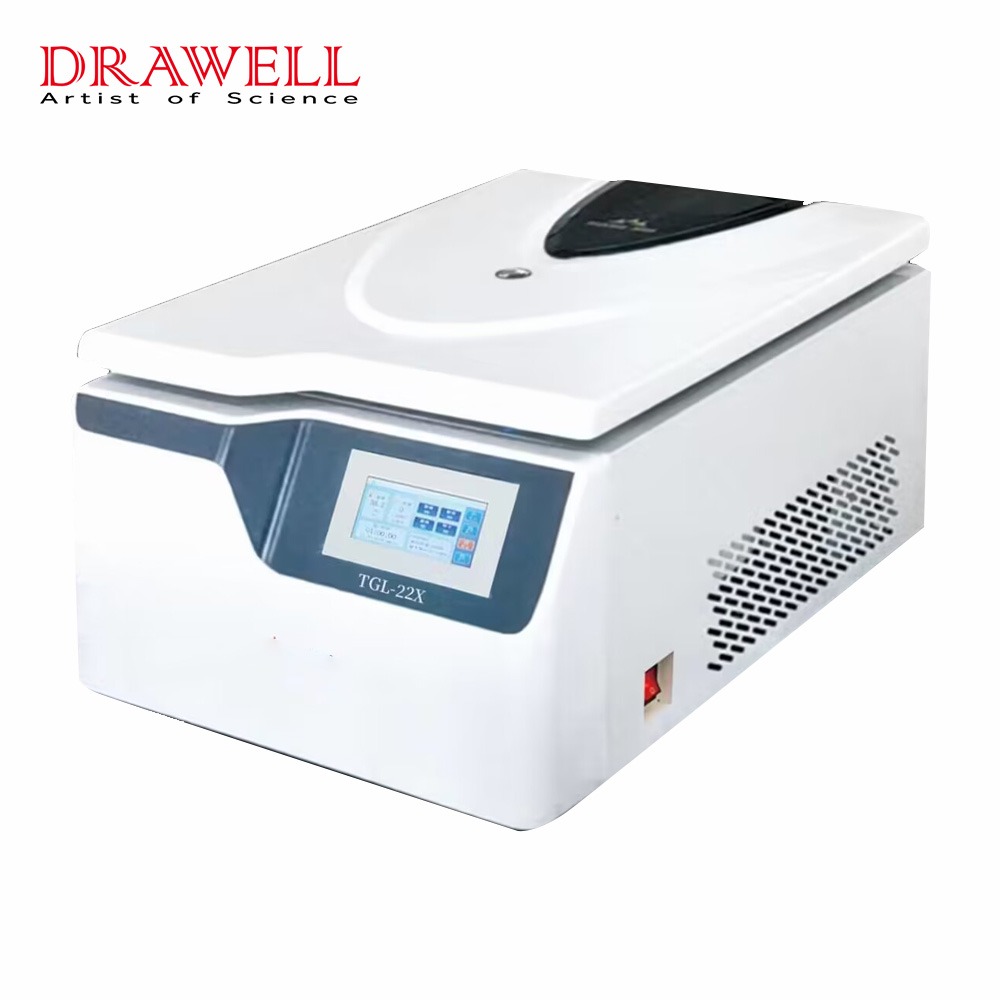

A centrifuge is a sophisticated piece of equipment with numerous components that work together to separate and analyze material.

- Rotor

The rotor is the centrifuge’s revolving component that contains sample containers such as centrifuge tubes or bottles. It is built to endure high speeds and comes in a variety of sizes and configurations to suit varied sample volumes and types. To provide the centrifugal force required for separation, the rotor rotates at high speeds.

- Motor

The motor drives the rotor’s rotation. It turns electrical energy into mechanical energy, which is then used to spin the rotor at the correct speed. The centrifuge’s control panel controls the motor, allowing users to set and alter the spinning speed to meet their unique needs.

- Control Panel

The control panel serves as the user interface for interacting with the centrifuge. It is made up of many buttons, knobs, and a digital display. Users can enter parameters like as speed, time, and temperature into the control panel. It also gives information on the centrifuge’s current operational state, such as rotation speed and remaining time.

- Safety Features

Centrifuges are outfitted with a variety of safety mechanisms to ensure their safe functioning. Lid locks, for example, prevent the lid from being opened while the rotor is spinning, ensuring the user’s safety. Imbalance detectors are also often used to detect any imbalance in the rotor and stop the centrifuge automatically to prevent damage or mishaps. Overheat protection, emergency stop buttons, and alarms are all possible safety measures.

- Lid and Interlock Mechanism

During operation, centrifuges feature a lid that covers the rotor and sample containers. The lid helps to keep the system closed, preventing sample contamination or leakage. The lid is frequently fitted with an interlock mechanism that prevents the centrifuge from operating until the lid is securely closed and locked in place.

- Display and Readout

A digital display or readout on centrifuges gives real-time information regarding the centrifugation process. This may include the current speed, elapsed time, remaining time, and other important statistics, allowing users to track the centrifugation’s progress.

Centrifugation Process in a Centrifuge

A centrifuge’s spinning process consists of multiple phases that allow things to be separated based on their density and molecular weight.

- Sample Preparation

The first step is to prepare the sample that will be centrifuged. The sample can be a liquid or a suspension comprising particles or components that need to be separated. To prevent leakage during centrifugation, ensure that the sample is correctly prepared and placed into appropriate containers, such as centrifuge tubes or bottles with secure lids.

- Loading of Sample Containers

The prepared sample is loaded into the sample containers with care. To ensure balance during centrifugation, the sample must be uniformly distributed between the containers. Imbalanced loading can create excessive vibration, which might damage the centrifuge or result in incorrect separation.

- Setting Parameters

The centrifuge has a control panel that allows users to configure various centrifugation parameters. These parameters are typically the intended rotating speed, time, and, in some cases, temperature. The specific parameters are determined by the type of the sample and the separation objectives.

- Acceleration

The centrifuge is started when the parameters have been established. Initially, the rotor gradually accelerates from a low speed to the ideal rotational speed. This acceleration phase allows for a steady increase in centrifugal force, which prevents sample disruption or spilling.

- Centrifugation

After reaching the desired speed, the centrifuge operates at a constant spinning speed. The high-speed rotation creates a centrifugal force that acts outward, causing denser particles or components within the sample to migrate to the sample container’s bottom. Lighter particles or components stay near the top.

- Deceleration and Braking

The centrifuge begins to decelerate at the end of the centrifugation phase. This progressive slowing helps the divided components to settle into their proper locations. The divided layers or components remain in place when the centrifuge comes to a complete halt.

- Sample Retrieval

The separated components can be carefully collected once the centrifuge has stopped for additional analysis or processing. Opening the sample containers, the desired components are removed using appropriate techniques such as pipetting or decanting.

The centrifugation process in a centrifuge allows for the effective separation and analysis of substances based on density and molecular weight, making it an important tool in a wide range of scientific, medicinal, and industrial applications.

Types of Centrifugation Used by a Centrifugation

Depending on the specific requirements of the separation process, many types of centrifugation procedures are used.

- Differential Centrifugation

The various sedimentation rates of particles or components in a sample due to their variable densities are the basis for this technique. It entails several rounds of increasing-speed centrifugation. Particles with greater densities sediment faster and form a pellet at the bottom of the tube on each round, whereas particles with lower densities remain in the supernatant. It is possible to separate particles based on their size and density by altering the centrifugation parameters and the number of rounds.

- Density Gradient Centrifugation

A density gradient medium, such as sucrose or cesium chloride, is used in this approach to establish a density gradient within the sample. The sample is put on top of the density gradient medium before centrifugation. As the rotor spins, particles or components migrate through the density gradient and settle at positions where their density matches the local density of the gradient. This technique enables the separation of particles based on their buoyant density, resulting in the formation of distinct bands or zones.

- Isopycnic Centrifugation

Isopycnic centrifugation separates particles purely on the basis of their buoyant density. A density gradient medium is meticulously created in this process to have a uniform density throughout. The sample is layered on top of the gradient, and centrifugation is done until the particles reach equilibrium, where their density equals that of the gradient medium. This method is very useful for sorting particles that have comparable densities but differ in size or form.

- Preparative Centrifugation

Preparative centrifugation is performed on a large scale to separate particles or components into purified samples. It entails the use of large-capacity centrifuges and sample containers. This technology enables greater sample volumes to be processed and bigger quantities of separated components to be collected for downstream applications.

- Analytical Centrifugation

Analytical centrifugation is a technique used to characterize and analyze particles or macromolecules in a sample. This method provides information about the components’ size, shape, and molecular weight. Sedimentation velocity, in which the movement of particles in response to centrifugal force is tracked over time, and sedimentation equilibrium, in which the sample is allowed to establish a steady-state particle distribution, are two analytical centrifugation procedures.

Each type of centrifugation process has distinct advantages and is best suited to specific applications. The technique used is determined by the nature of the sample, the desired separation goals, and the equipment available. Centrifugation techniques are critical in many domains, including molecular biology, biochemistry, clinical diagnostics, and pharmaceutical research.

Summary

A centrifuge is a powerful and flexible apparatus that separates materials depending on their density and molecular weight using centrifugal force. A centrifuge works by utilizing the power of centrifugal force to achieve efficient separation, making it a vital tool in a variety of industries where sample separation and analysis are necessary.